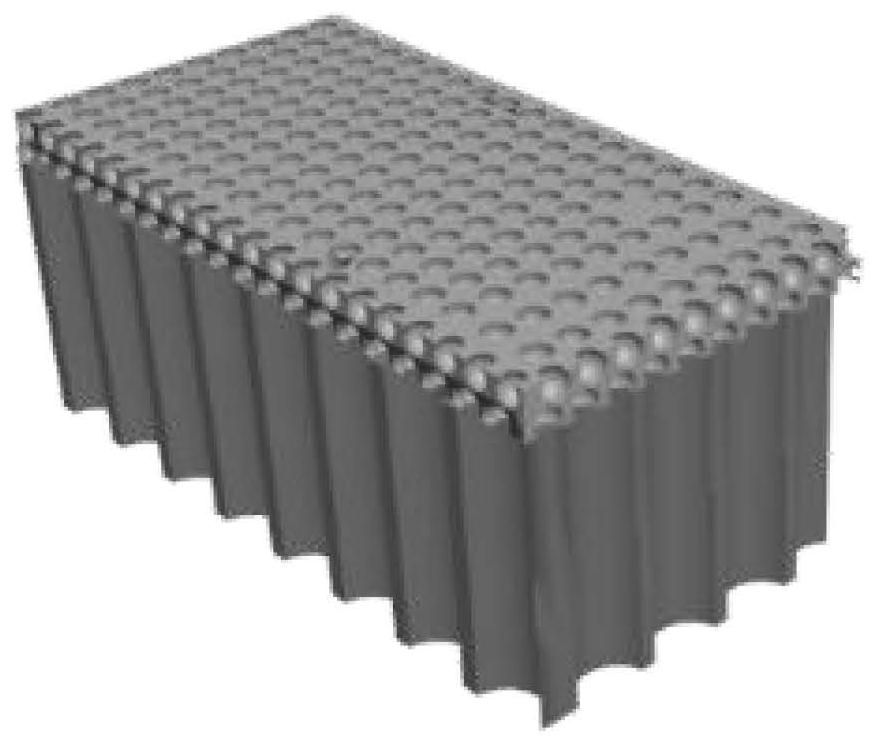

Mesoporous silica/anodic aluminum oxide heterojunction membrane as well as super-assembly preparation method and application thereof

A technology of anodized aluminum and mesoporous silicon oxide, applied in mechanical equipment, liquid chemical plating, machines/engines, etc., can solve problems such as unfavorable energy capture and increased ion transmission resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This example describes in detail the mesoporous silica / anodized alumina heterojunction, its preparation method and application.

[0051] In step S0, an AAO film with a diameter of 15 mm, a thickness of 60 μm, and a pore diameter of 80 nm is used as a base, and 8 wt % polymethyl methacrylate (PMMA) is used to spin-coat the surface of the anodized aluminum film to plug the pores, and then polished for later use .

[0052] Step 1, prepare the silicon precursor solution: Weigh 0.9g of the template agent F127 and dissolve it in 10g of absolute ethanol to obtain the template agent solution, mix 0.4g of 0.1M dilute hydrochloric acid, 0.5g of deionized water and 10.0g of After mixing absolute ethanol, stir magnetically to obtain a mixed solution, then slowly add 2.08g of silicon source tetraethyl orthosilicate (TEOS) dropwise into the mixed solution, stir at room temperature for 30min, and then heat at 60°C for 1h to obtain a silica gel. After cooling to room temperature, the ...

Embodiment 2

[0060] This example describes in detail the MS / AAO heterogeneous conjunctiva, preparation method and application.

[0061] In this embodiment, except for the spin-coating step, other operations are the same as those in Embodiment 1, and will not be repeated here.

[0062] The mass molar ratio of template agent F127 to tetraethyl orthosilicate is 90 g / mol.

[0063] In step 2, the silicon precursor solution is spin-coated on one side of the AAO with plugged pores at a speed of 1000 r to obtain a composite membrane. The time for one spin coating is 30s, and the number of spin coatings is 2 times.

Embodiment 3

[0065] This example describes in detail the MS / AAO heterogeneous conjunctiva, preparation method and application.

[0066] In this embodiment, except for the spin-coating step, other operations are the same as those in Embodiment 1, and will not be repeated here.

[0067] The mass molar ratio of template agent F127 to tetraethyl orthosilicate is 90 g / mol.

[0068] Step 2: Spin-coat the silicon precursor solution onto one side of the AAO with plugged pores at a speed of 2000 r to obtain a composite membrane. The time for one spin coating is 30s, and the number of spin coatings is 3 times.

[0069] The MS / AAO heterogeneous conjunctiva prepared in Examples 2 and 3 were tested, and the test results are shown in Figure 5 , 7 .

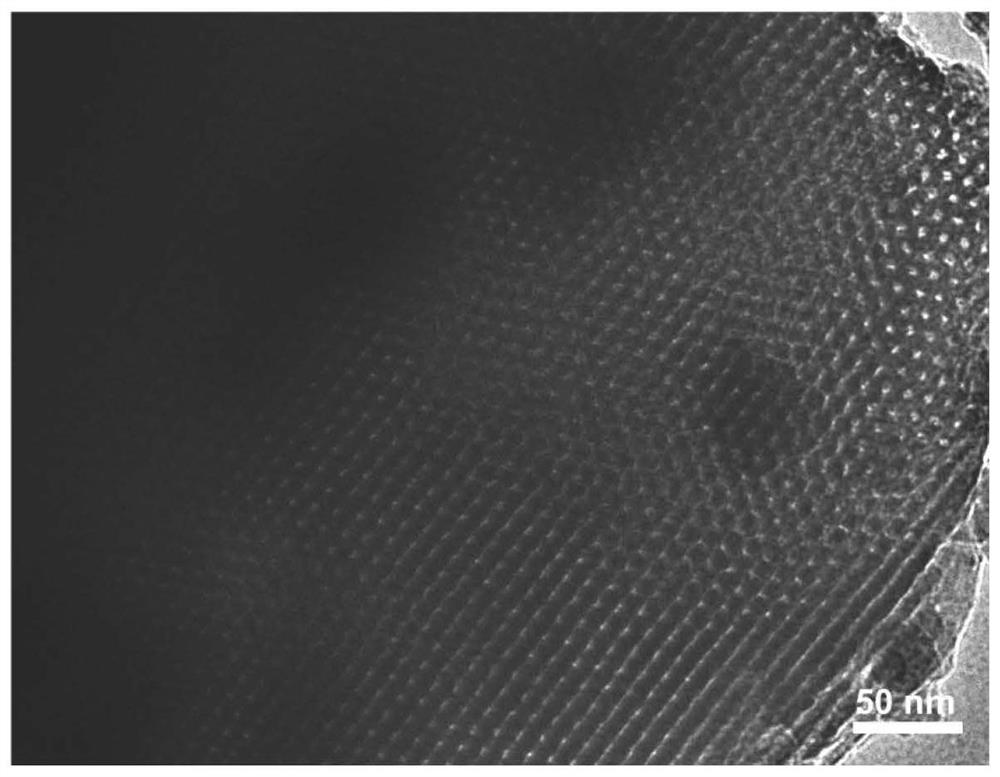

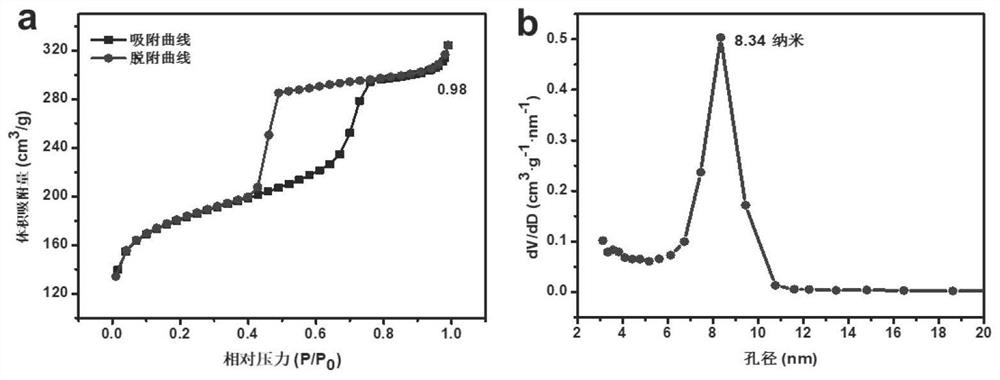

[0070] Figure 5 It is a scanning electron microscope image of the mesoporous silicon oxide / anodized aluminum oxide heterojunction film in Examples 2 and 3 of the present invention; Figure 6 It is a cross-sectional scanning electron microscope image...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com