Tempering process based on metal heat treatment

A technology of metal heat treatment and process, which is applied in the direction of metal material coating process, heating inorganic powder coating, coating, etc., can solve the problems of the influence of the overall strength of the metal, the reduction of the service life, the influence of the metal strength, etc., and achieve good bonding, The effect of high metal strength and guaranteed efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

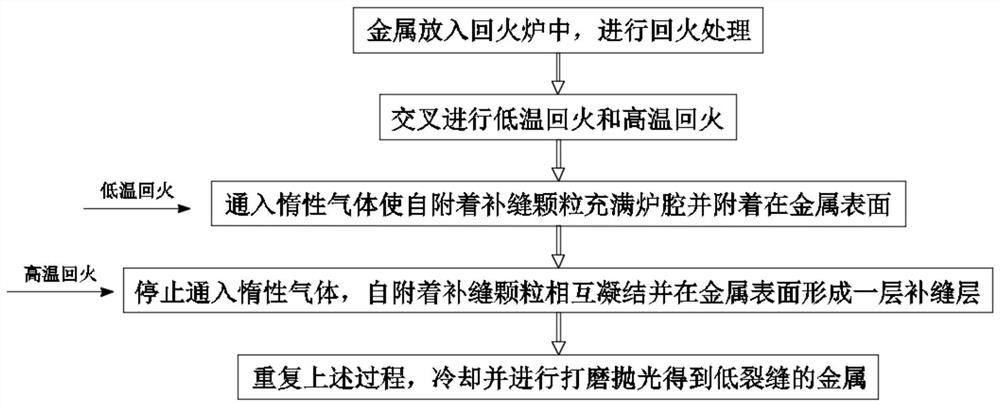

[0049] see figure 1 , a tempering process based on metal heat treatment, comprising the following steps:

[0050] S1, first put the metal that has been annealed, normalized, and quenched into the tempering furnace for tempering treatment;

[0051] S2. Low-temperature tempering and high-temperature tempering are performed alternately, and the temperature is continuously changed back and forth between the temperature gaps of high-temperature tempering and low-temperature tempering;

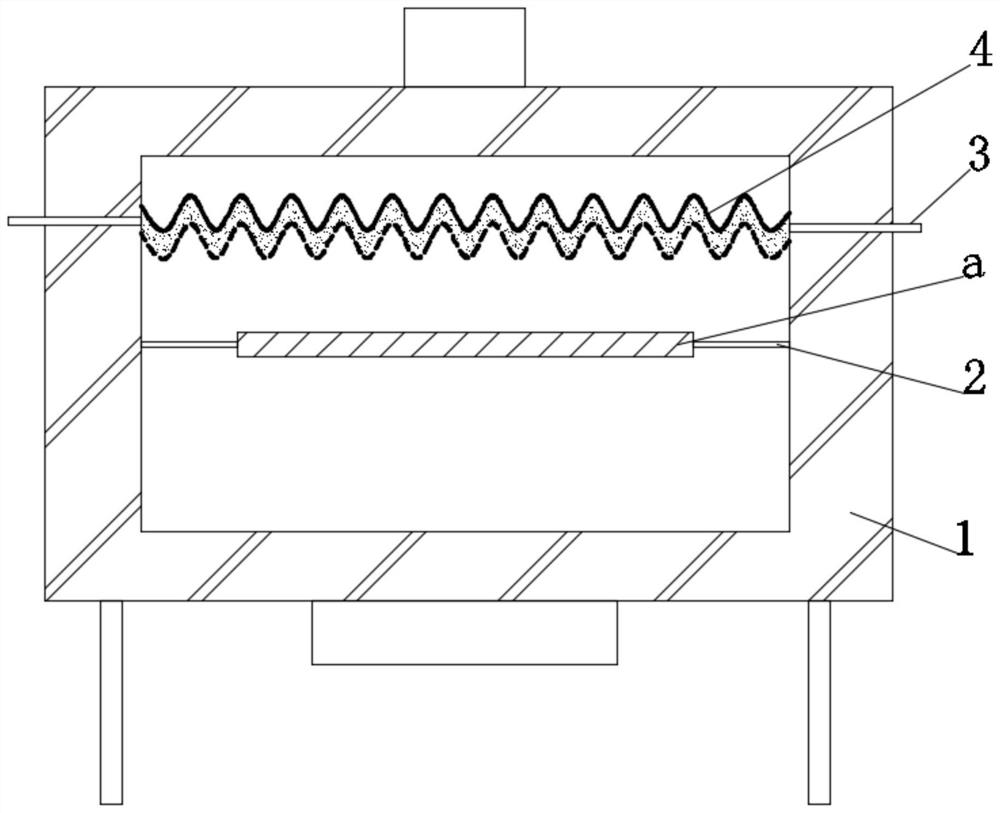

[0052] S31. During low-temperature tempering, inert gas is introduced into the furnace chamber of the tempering furnace, thereby driving the self-attached seam-filling particles in the semi-transparent torsion rod 4 to fill the furnace chamber and adhere to the metal surface;

[0053] S32. Please refer to Figure 4 , when tempering at high temperature, stop the introduction of gas, and use the electrostatic generator to generate static electricity on the semi-transparent torsion rod 4, and absorb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com