High-toughness polyester resin and synthetic method thereof

A technology of polyester resin and synthesis method, which is applied in the field of high-toughness polyester resin and its synthesis, can solve the problems of increased resin and filler ratio, increased cost, and more resins, etc., and achieves good wettability, high chemical resistance, The effect of high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

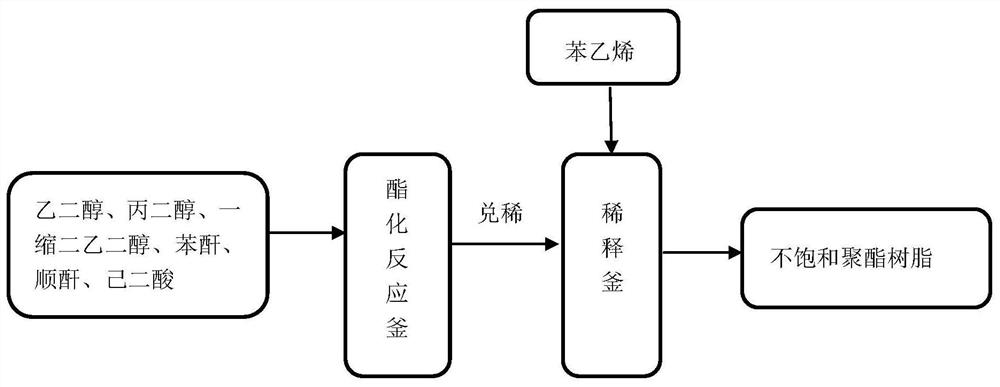

Method used

Image

Examples

Embodiment 1

[0068] The high toughness polyester resin described in the present embodiment 1, by mass percentage, raw material composition is as follows:

[0069]

[0070] The laboratory synthesis 5kg high-toughness polyester resin described in present embodiment 1 is made up of the following steps:

[0071] (1) Feed intake in reaction bottle, drop into ethylene glycol 506g, propylene glycol 135g, diethylene glycol 843g, triphenyl phosphite 2.5g, phthalic anhydride 1518g, maleic anhydride 607g, hexanoic anhydride respectively Diacid 34g, blow nitrogen, heat up to a temperature of 60°C, maleic anhydride is basically dissolved in alcohol, start stirring and continue to heat up.

[0072] (2) When the temperature is raised to 156°C, the output water of the alkyd condensation reaction increases rapidly, and the temperature of the distillation head begins to rise to 97±2°C, and the water is kept at this outlet temperature for 1.5 hours.

[0073] (3) Raise the temperature evenly at 4.5°C / 10mi...

Embodiment 2

[0094] The high toughness polyester resin described in the present embodiment 2, by mass percentage, the raw material composition is as follows:

[0095]

[0096] The production 30 tons of high-toughness polyester resins described in present embodiment 2 is made up of the following steps:

[0097] (1) Feeding: firstly throw ethylene glycol 3036kg, propylene glycol 810kg, diethylene glycol 5060kg, then throw triphenyl phosphite 12kg, then throw phthalic anhydride 9110kg, maleic anhydride 3644kg, adipic anhydride Acid 202kg.

[0098] (2) Nitrogen blowing: first pass nitrogen gas to the reaction kettle for 15 minutes, then reduce the nitrogen gas to enter the heating state.

[0099] (3) Heating: When the temperature of the distillation head is 90°C, pass the cooling water to the vertical condenser, and heat up to the outlet water at a constant speed for 1.0h. Raise the temperature at 15±1°C / h (control the heating rate according to the condition of the distillation head), and...

Embodiment 3

[0114]The high toughness polyester resin described in the present embodiment 3, by mass percentage, raw material composition is as follows:

[0115]

[0116] The production 30 tons of high-toughness polyester resins described in present embodiment 3 is made up of the following steps:

[0117] (1) Feeding: first throw ethylene glycol 3600kg, propylene glycol 850kg, diethylene glycol 5400kg, triethylene glycol 530kg, tetraethylene glycol 1053kg, neopentyl glycol 220kg, then throw triphenyl phosphite 3kg, and then throw 6624kg of phthalic anhydride, 3283kg of maleic anhydride, 600kg of adipic acid, 1165kg of fumaric acid, and 540kg of isophthalic acid.

[0118] (2) Nitrogen blowing: first pass nitrogen gas to the reaction kettle for 15 minutes, then reduce the nitrogen gas to enter the heating state.

[0119] (3) Heating: When the temperature of the distillation head is 90°C, pass the cooling water to the vertical condenser, and heat up to the outlet water at a constant speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com