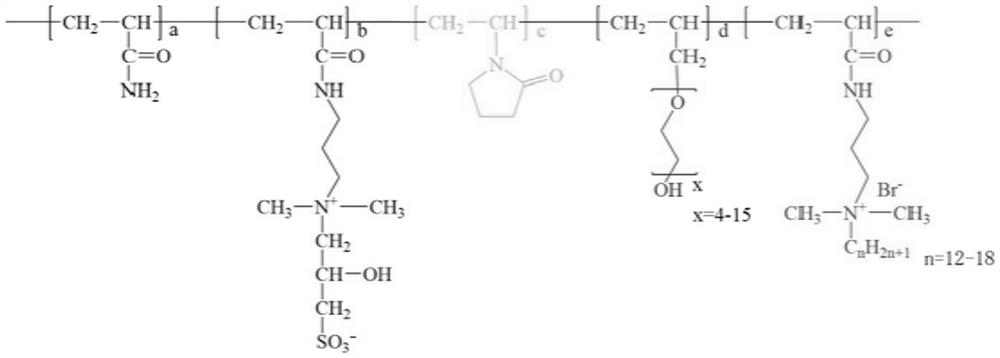

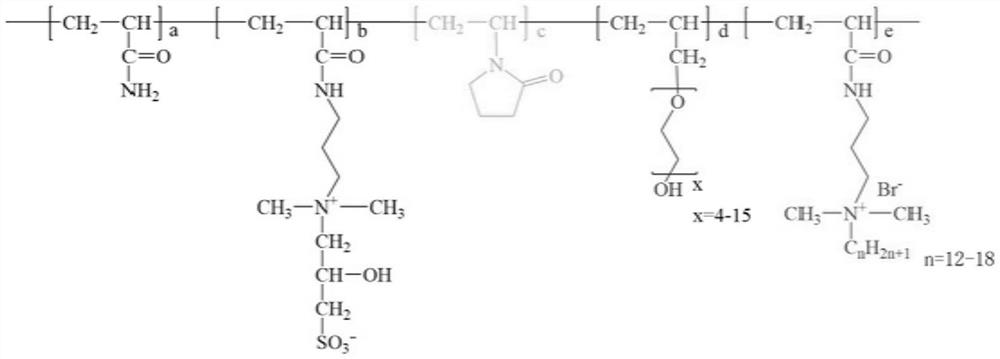

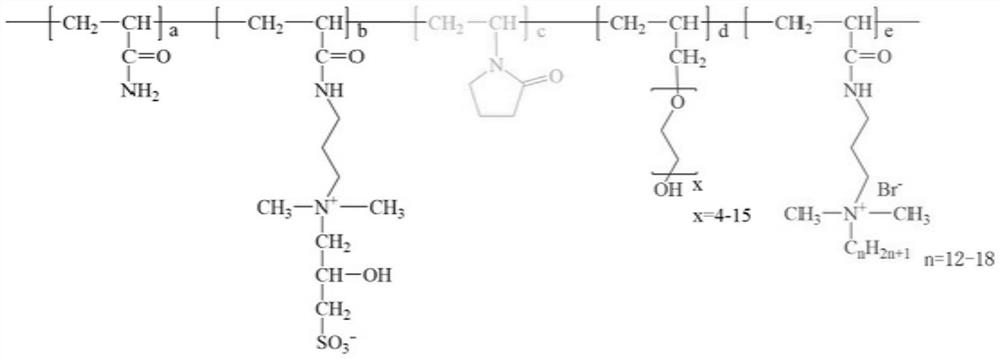

Acid-resistant resistance reducing agent, preparation method thereof and acid-resistant slickwater fracturing fluid system

A drag reducing agent and system technology, applied in the field of recyclable fracturing fluid in oil and gas fields, can solve the problems of not having acid resistance, incomplete degradation, reservoir damage, etc., and achieve good reservoir adaptability and core permeability damage Effect of low and fast dissolution properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the above-mentioned acid-resistant drag-reducing agent comprises the following steps:

[0031] Step 1. In parts by mass, 80-100 parts of hydrophobic monomers, 5-10 parts of salt-tolerant monomers, 5-10 parts of shear-resistant monomers, 60-100 parts of water-soluble monomers, 90-100 parts of Parts of ammonium sulfate and a certain amount of water, stirred until dissolved to obtain the mixed system a.

[0032] Step 2: Add 20 parts of sodium hydroxide solution and a certain amount of water to 100 parts of the mixed system a in parts by mass to obtain a monomer mixed solution.

[0033] Step 3, remove the oxygen in the monomer solution, and add 0.05 parts of oxidizing initiator and 1 part of 2,3,5,6-tetrahydroxy-2- The aqueous solution of hexenoic acid-4-lactone is subjected to a polymerization reaction, and when the temperature is higher than 40° C., it is reacted in a water bath for 8 hours to obtain a white and transparent acid-resistant drag-r...

Embodiment 1

[0040] A preparation method of an acid-resistant drag reducing agent, comprising the following steps:

[0041] Step 1. In parts by mass, 80 parts of acryloylpropyl dimethyl dodecyl ammonium bromide, 5 parts of acryloyl propyl dimethyl sulfobetaine, 5-10 parts of N-ethylene Base pyrrolidone, 60 parts of allyl polyoxyethylene ether, 90-100 parts of ammonium sulfate and a certain amount of water, and stir until dissolved to obtain the mixed system a.

[0042] Step 2: Add 20 parts of sodium hydroxide solution and a certain amount of water to 100 parts of the mixed system a in parts by mass to obtain a monomer mixed solution.

[0043] Step 3, remove the oxygen in the monomer solution, and add 0.05 parts of 1% wt potassium persulfate aqueous solution and 1 part of 2,3,5,6-tetrahydroxy - 2-hexenoic acid-4-lactone aqueous solution is polymerized, and when the temperature is higher than 40°C, it is reacted in a water bath for 8 hours to obtain a white and transparent acid-resistant dr...

Embodiment 2

[0045] A preparation method of an acid-resistant drag reducing agent, comprising the following steps:

[0046] Step 1, in parts by mass, 90 parts of acryloyl propyl dimethyltetradecyl ammonium bromide, 7 parts of 2-acrylamido-2-methylpropanesulfonic acid, 8 parts of chitosan, 80 parts of dimethylaminoethyl acrylate, 90-100 parts of ammonium sulfate and a certain amount of water are stirred until dissolved to obtain the mixed system a.

[0047] Step 2: Add 20 parts of sodium hydroxide solution and a certain amount of water to 100 parts of the mixed system a in parts by mass to obtain a monomer mixed solution.

[0048] Step 3, remove the oxygen in the monomer solution, and add 0.05 parts of 1% wt potassium persulfate aqueous solution and 1 part of 2,3,5,6-tetrahydroxy - 2-hexenoic acid-4-lactone aqueous solution is polymerized, and when the temperature is higher than 40°C, it is reacted in a water bath for 8 hours to obtain a white and transparent acid-resistant drag-reducing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com