Fixed bed reactor for methane oxidative coupling reaction and method for preparing ethylene by methane oxidative coupling

A fixed bed reactor, oxidative coupling reaction technology, applied in chemical instruments and methods, condensation hydrocarbon production with dehydrogenated hydrocarbons, organic chemistry, etc., can solve problems such as poor industrial implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

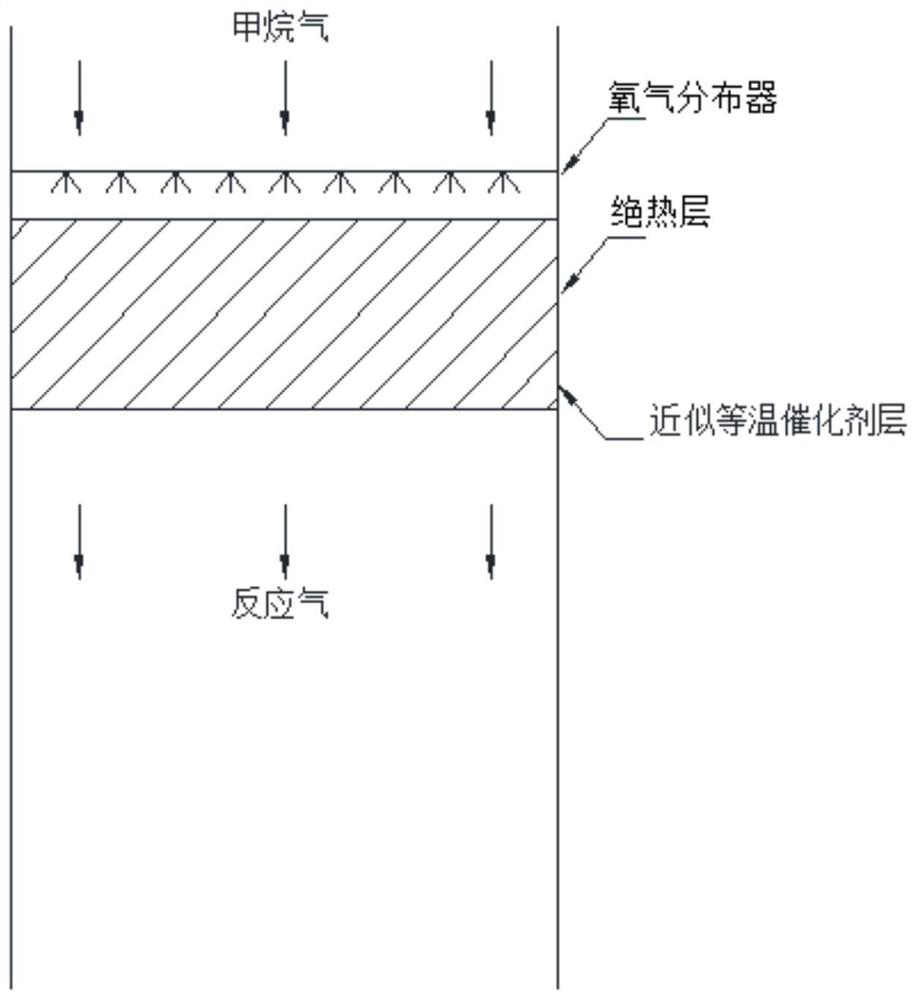

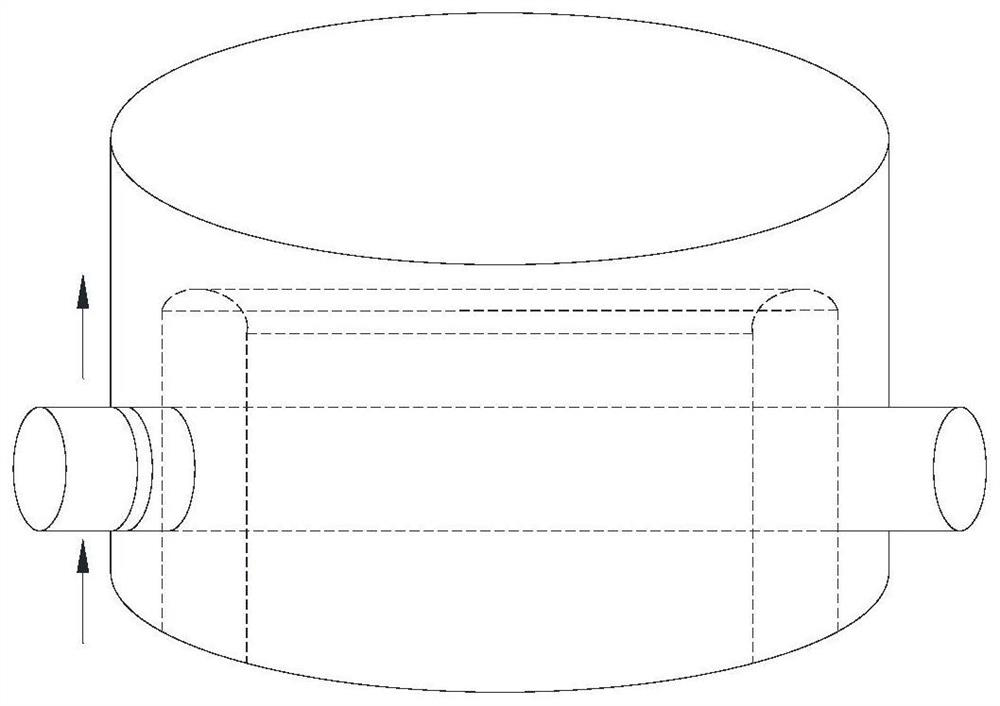

[0031] Such as figure 1 A fixed-bed reactor for methane oxidative coupling reaction shown, the reactor includes a reactor shell (cylindrical body) and an oxygen distributor arranged in the reactor shell, a catalyst bed, 12 U-shaped heat extraction tube bundle, high-pressure steam superheating section; the oxygen distributor is arranged on the upper part of the catalyst bed, and the high-pressure steam superheating section is arranged on the lower part of the catalyst bed;

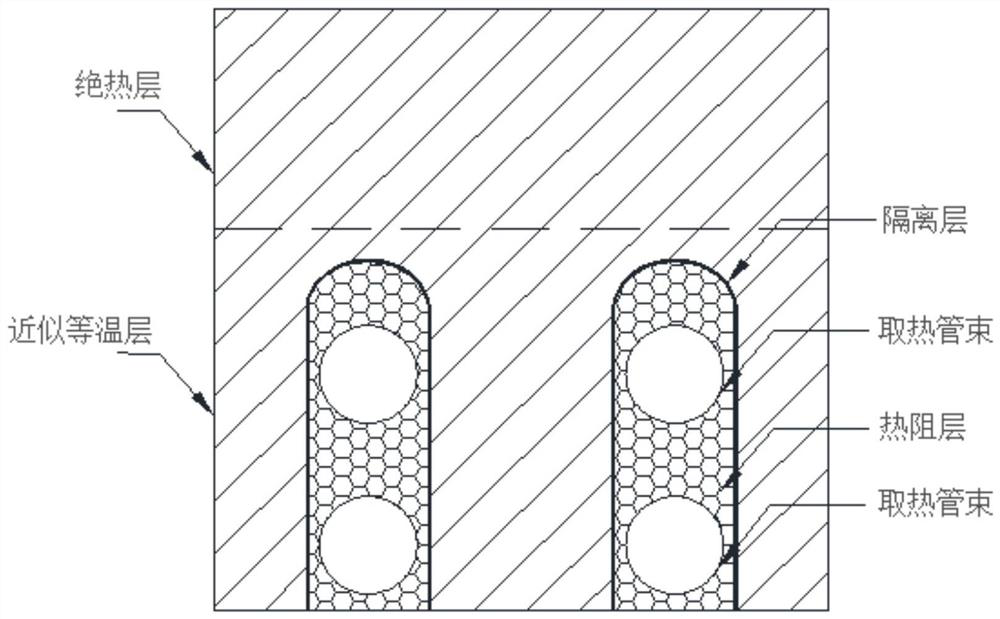

[0032] Such as figure 2 and image 3 As shown, the catalyst bed is divided into upper and lower layers, the upper layer is an insulating layer, and the lower layer is an approximately isothermal layer. The U-shaped heat extraction tube bundle is arranged in the approximate isothermal layer, and 4 U-shaped heat extraction tube bundles are used for high pressure saturation. Steam, 4 U-shaped heat extraction tube bundles are used to superheat high-pressure saturated steam. Valves are installed on the 4 U-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com