Self-repair type high-precision intelligent variable-frequency speed regulating mechanism

A variable frequency speed regulation, high-precision technology, applied in mechanical equipment, engine control, machine/engine, etc., can solve the problems of increased deformation of connecting rods, fatigue deformation, damage, etc., to ensure high efficiency and uniformity, improve anti-corrosion Deformation effect, effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

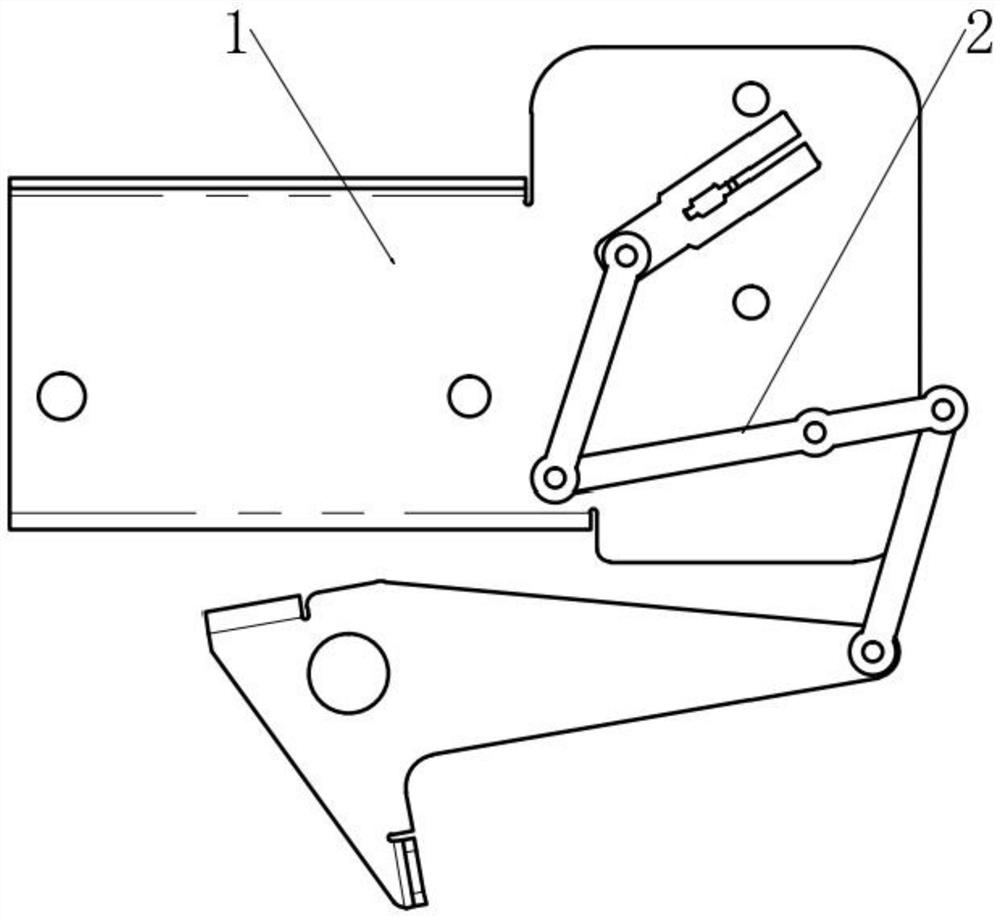

[0043] see Figure 1-2 , a self-repairing high-precision intelligent frequency conversion speed regulating mechanism, including a mounting plate 1, a multi-link mechanism is installed on the mounting plate 1, the multi-link mechanism includes a plurality of connecting rods 2 connected end to end, and the connecting rod 2 includes a connecting rod The main body 21 and the repair protective cover 22 wrapped on the outer surface of the connecting rod body 21, the repair protective cover 22 is made of hard heat insulating material, the repair protective cover 22 can protect the connecting rod body 21 on the one hand, and the other On the one hand, it can be used for heat preservation to prevent heat loss, and can also reduce its own thermal expansion, so as to ensure the stability of the repair of the thermal expansion repair block 5 .

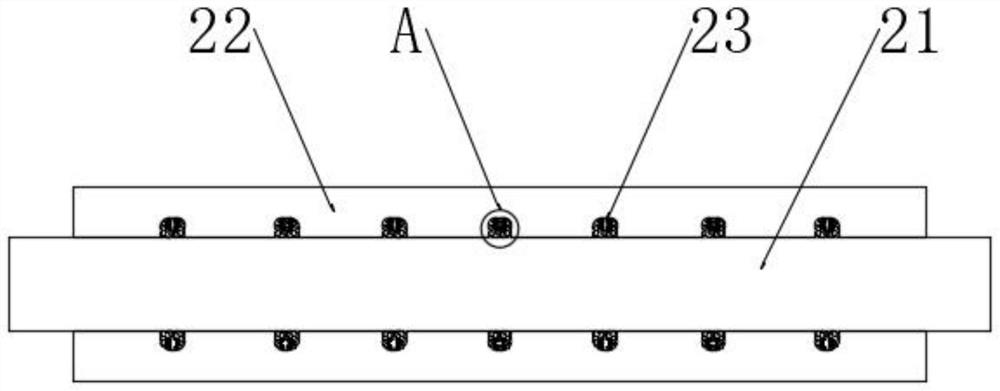

[0044] see image 3 There are a plurality of evenly distributed repair grooves 23 on the inner surface of the repair protective cover 22, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com