Preparation of flexible self-supporting single crystal magnetic Fe3O4 thin film material, thin film material, application and single crystal structure

A thin film material and single crystal structure technology, applied in the direction of material selection, polycrystalline material growth, single crystal growth, etc., can solve problems such as unsatisfactory and impossible to prepare single crystal Fe thin film, achieve less self-supporting characteristics, and benefit The effect of promoting production and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

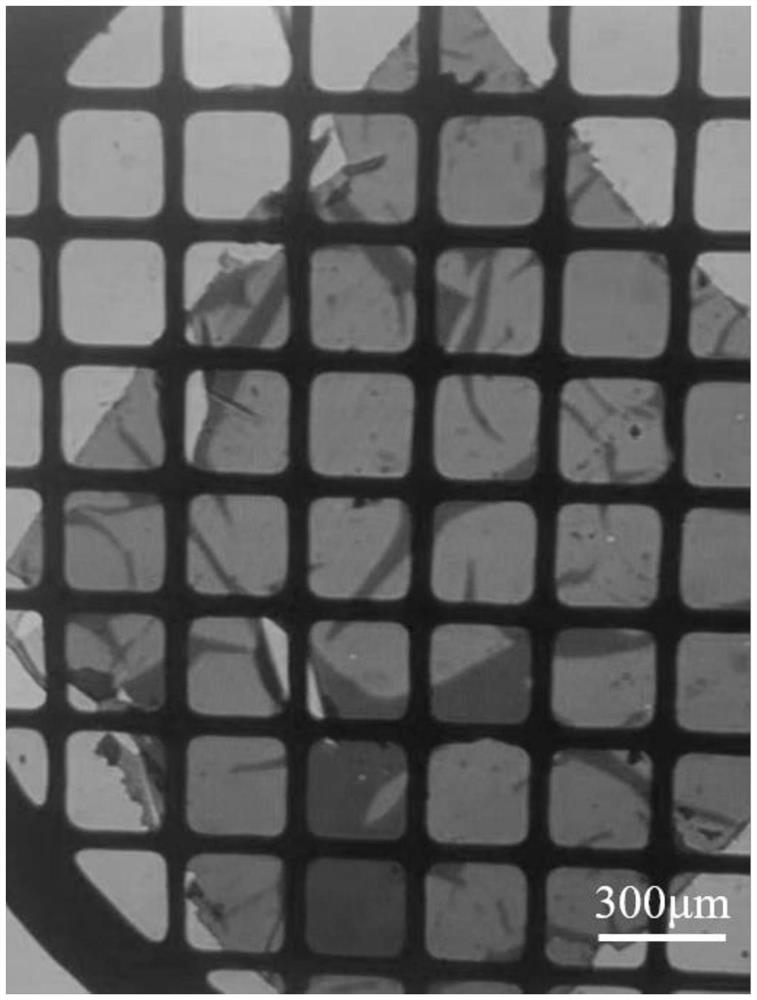

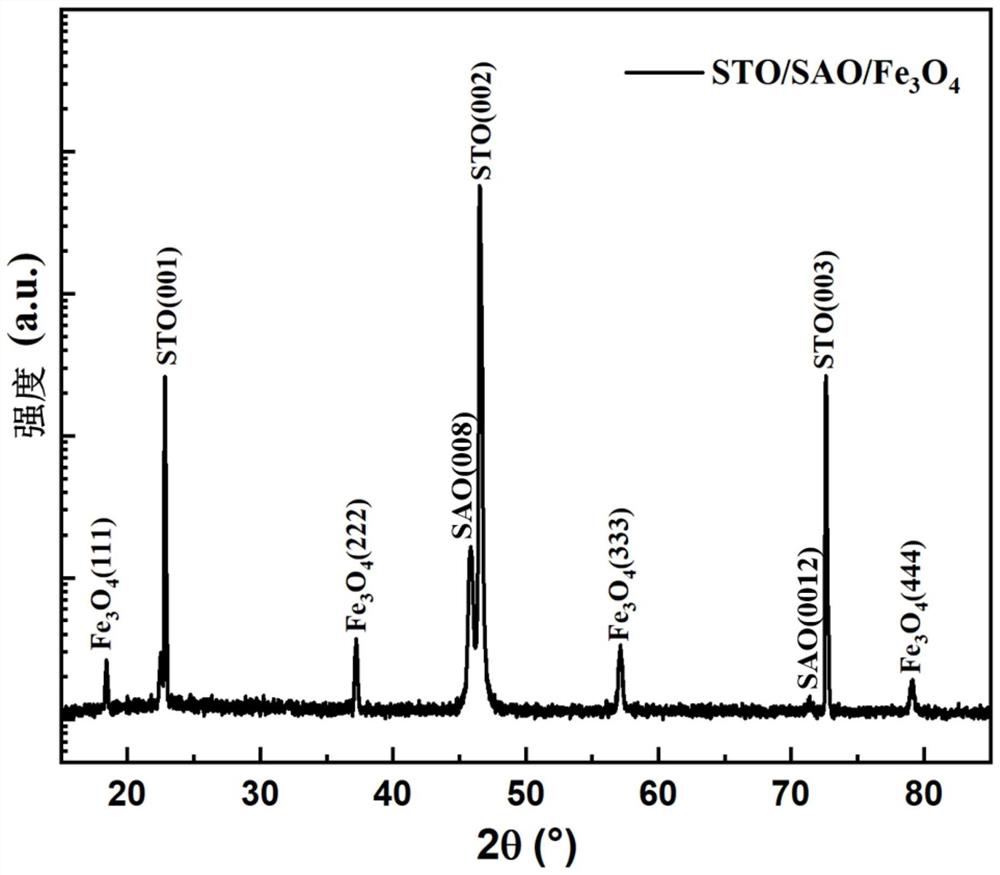

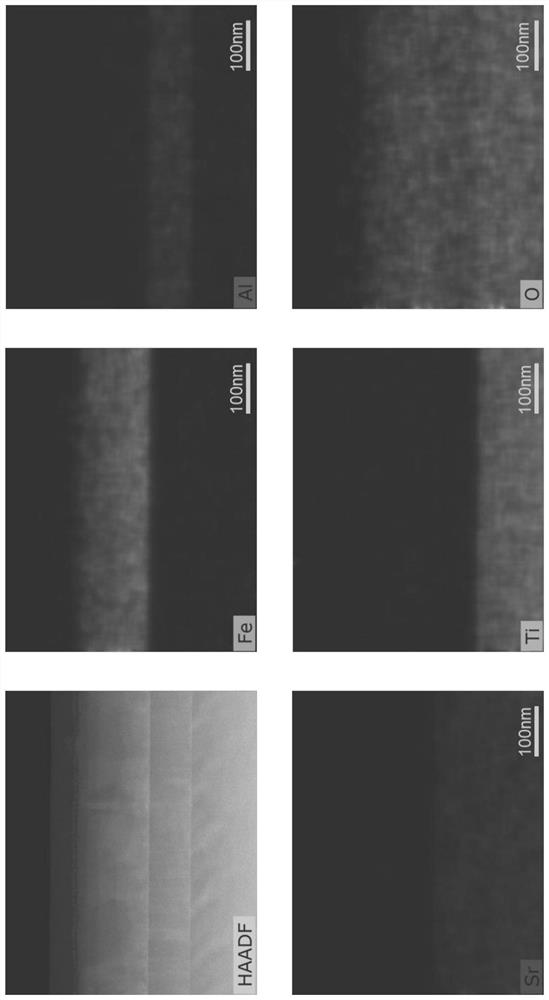

[0059] A flexible self-supporting single crystal magnetic Fe 3 o 4 The preparation method of film material, comprises the following steps:

[0060] (1) Select the STO (001) substrate and preprocess it, including the following steps:

[0061] a. Immerse the STO (001) substrate in acetone and ultrasonically clean it at 60 °C for 10 min;

[0062] b. Then immerse the STO (001) substrate in absolute ethanol, and ultrasonically clean it for 5 minutes;

[0063] c. Next, immerse the STO (001) substrate in deionized water and ultrasonically clean it for 5 minutes;

[0064] d. Finally, dry the STO (001) substrate with nitrogen.

[0065] (2) The single crystal SAO layer and Fe 3 o 4 Thin film material specifically comprises the following steps:

[0066] (a) Paste the STO (001) substrate pretreated in step (1) on the SiC heat conduction sheet with silver paste, and then heat and dry;

[0067] (b) Place the SiC heat conduction sheet pasted with the STO(001) substrate on the laser hea...

Embodiment 2

[0080] A flexible self-supporting single crystal magnetic Fe 3 o 4 The preparation method of film material, comprises the following steps:

[0081] (1) Select the STO (001) substrate and preprocess it, including the following steps:

[0082] a. Immerse the STO (001) substrate in acetone and ultrasonically clean it at 60°C for 10 min;

[0083] b. Then immerse the STO (001) substrate in absolute ethanol, and ultrasonically clean it for 5 minutes;

[0084] c. Next, immerse the STO (001) substrate in deionized water and ultrasonically clean it for 5 minutes;

[0085] d. Finally, dry the STO (001) substrate with nitrogen.

[0086] (2) The single crystal SAO layer and Fe 3 o 4 Thin film material specifically comprises the following steps:

[0087] (a) Paste the STO (001) substrate pretreated in step (1) on the SiC heat conduction sheet with silver paste, and then heat and dry;

[0088] (b) Place the SiC heat conduction sheet pasted with the STO(001) substrate on the laser he...

Embodiment 3

[0097] A flexible self-supporting single crystal magnetic Fe 3 o 4 The preparation method of film material, comprises the following steps:

[0098] (1) Select the STO (001) substrate and preprocess it, including the following steps:

[0099] a. Immerse the STO (001) substrate in acetone and ultrasonically clean it at 60°C for 10 min;

[0100] b. Then immerse the STO (001) substrate in absolute ethanol, and ultrasonically clean it for 5 minutes;

[0101] c. Next, immerse the STO (001) substrate in deionized water and ultrasonically clean it for 5 minutes;

[0102] d. Finally, dry the STO (001) substrate with nitrogen.

[0103] (2) The single crystal SAO layer and Fe 3 o 4 Thin film material specifically comprises the following steps:

[0104] (a) Paste the STO (001) substrate pretreated in step (1) on the SiC heat conduction sheet with silver paste, and then heat and dry;

[0105] (b) Place the SiC heat conduction sheet pasted with the STO(001) substrate on the laser he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com