Lifting type chemical plating tank system convenient to clean quickly

An electroless plating tank, lift-type technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems affecting the production efficiency of enterprises, low safety, low cleaning speed, etc. The effect of automatic replenishment, accurate fluid replenishment flow, and uniform temperature of the medicinal solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following describes the application in further detail through specific embodiments in conjunction with the accompanying drawings, but the application is not limited to the following embodiments.

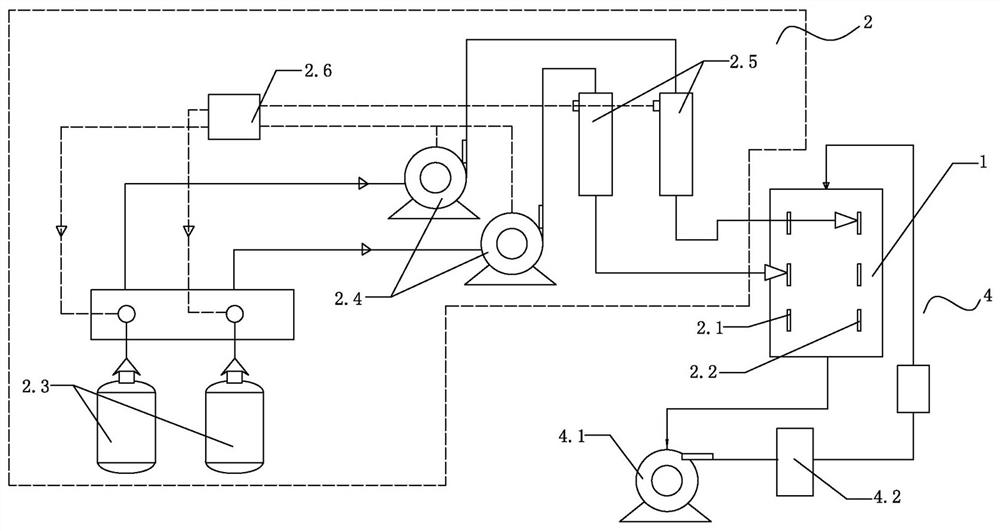

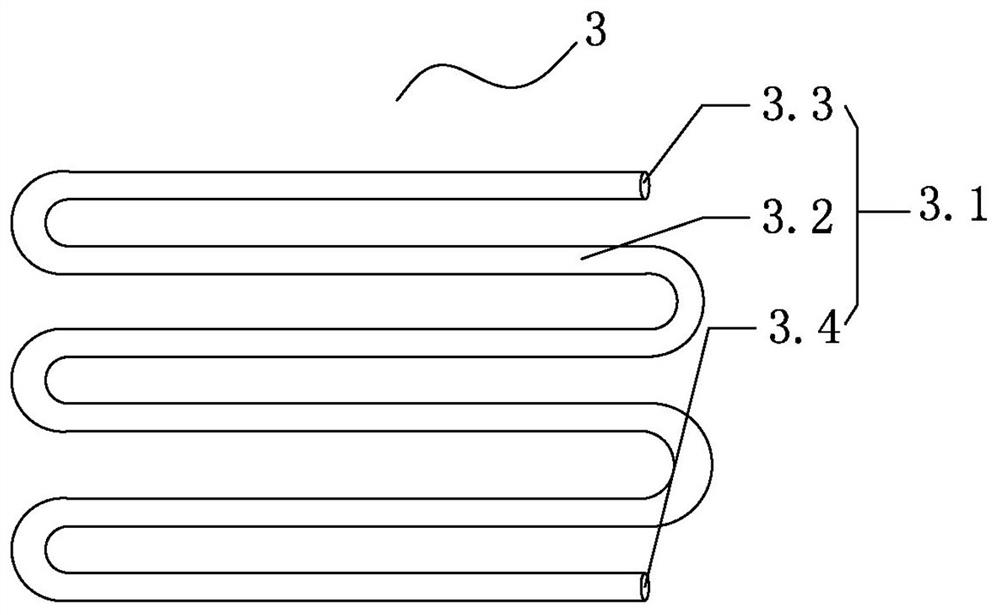

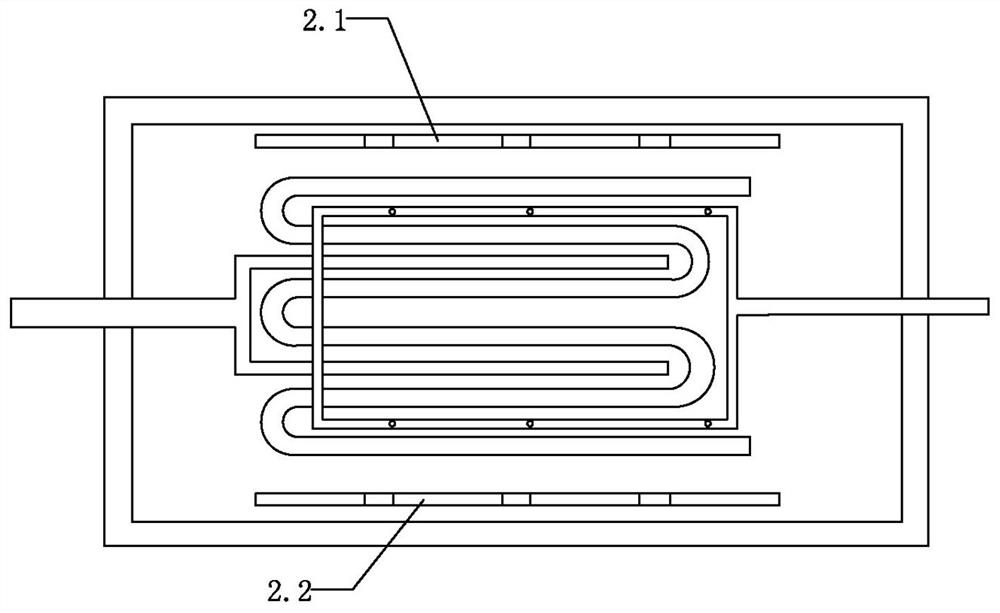

[0031] as attached figure 1 , 6 Shown: a kind of lifting type electroless plating tank system that is convenient for quick cleaning of the present application, this system comprises plating tank 1 and replenishment device 2, plating tank comprises square plating tank body 1.1, and this replenishment device 2 includes chemical solution (plating solution concentrated solution) pipeline 2.1 and lye pipeline 2.2, which are used to supplement the plating solution and lye in the plating tank body 1.1 respectively; the system also includes a heating system 3 and an external circulation system 4, the heating system 3 is used In order to heat the solution in the plating tank body 1.1, the peripheral circulation system 4 allows the solution in the tank body 1.1 to flow, thereby imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com