Combined hub and hub machining method

A processing method and combined technology, applied in the direction of spoked wheels, wheels, wheel manufacturing, etc., can solve problems such as porosity defects, residual stress affecting material properties, and reducing material strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The core of the present invention is to provide a combined hub, which improves the yield and reduces the processing flow by adopting a split structure design.

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, the combined hub and hub processing method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

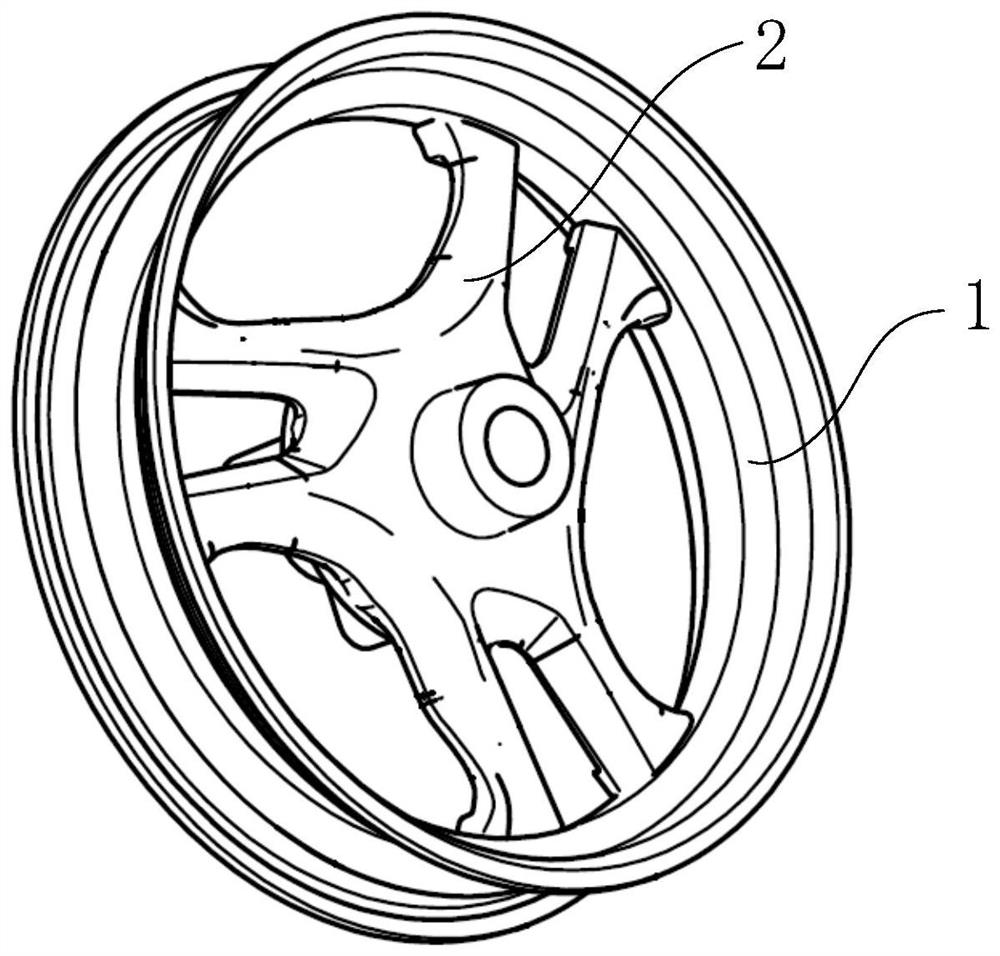

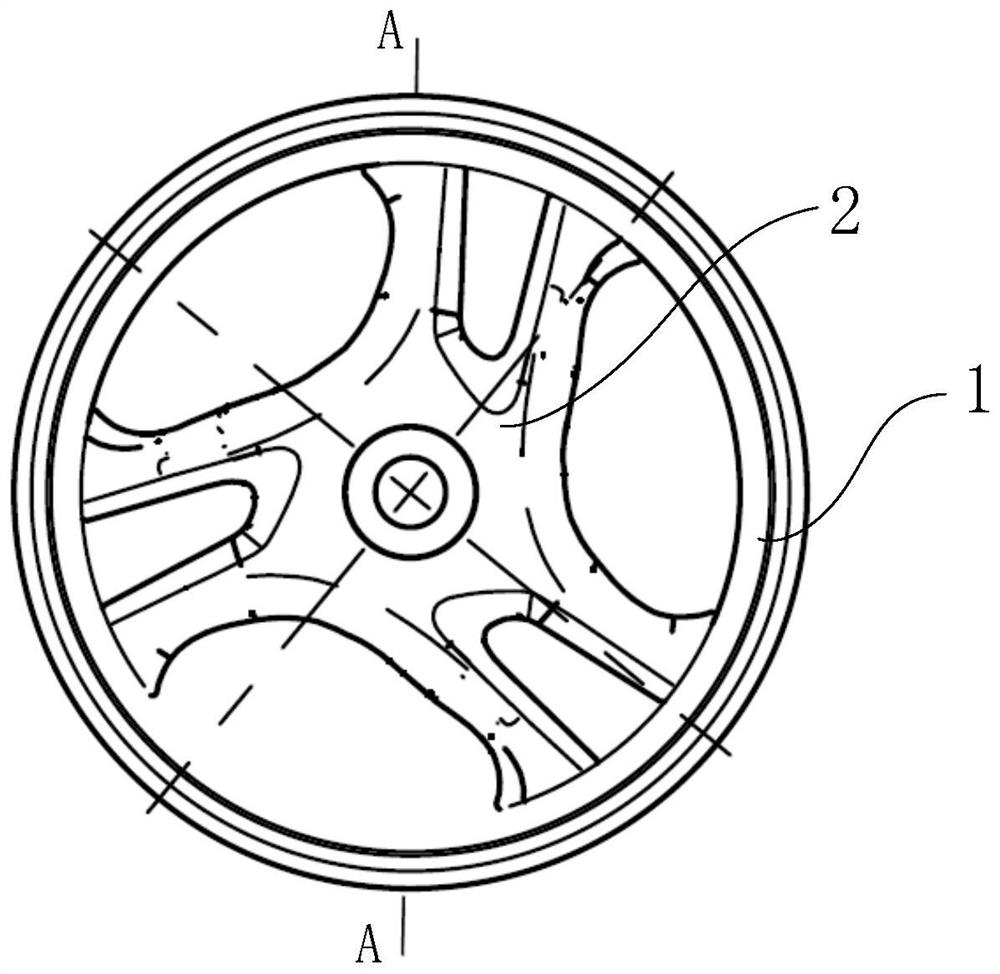

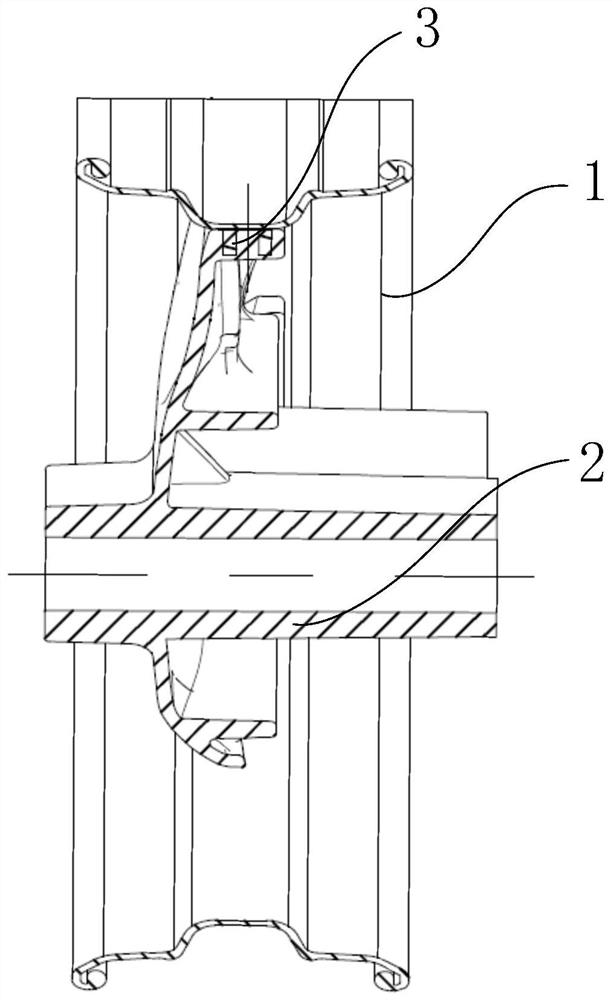

[0035] Such as Figure 1A As shown, it is an axonometric view of a specific structure of the combined hub provided by the present invention, which includes a rim 1 and a spoke 2 arranged separately, Figure 1B for Figure 1A Front view of the structure shown, Figure 1C for Figure 1B The cross-sectional view of the A-A direction in the middle; the rim 1 is a circular ring, the outside is used to fit the tire, and the rim 1 is a structure made by independent processing; figure 2 As shown, it is the axonometric structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com