Solid electrolyte, preparation method thereof, and lithium secondary solid state battery

A technology of solid electrolyte and lithium salt, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of high cost and complicated preparation methods, and achieve high production efficiency, simple preparation process, and improved cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the solid electrolyte of the present invention comprises the following steps:

[0051] a, mixing the polymer substrate, lithium salt and additives to obtain a slurry;

[0052] b. The slurry is formed into a film, and then dried to obtain a solid electrolyte;

[0053] In one embodiment, step a can specifically adopt the following method:

[0054] (1) Select polymer substrates, additives, and select a certain quality of solvents, including but not limited to NMP, DMF, etc., calculated by mass ratio, controlled at 60% to 85% of the total amount of slurry;

[0055] (2) adding the polymer substrate into the solvent, and stirring at room temperature for 1 to 2 hours to form a stable and uniform transparent colloid;

[0056] (3) Ultrasonic disperse the additive in a solvent whose total mass of the slurry is 10% for 10 minutes to 1 hour.

[0057] (4) Add the supersonicated additive and lithium salt directly to the glue solution prepared in step (2),...

Embodiment 1

[0064] Synthesis of Ta-doped β-LiAlSi 2 o 6 , the synthesis steps are as follows:

[0065] (1) LiOH·H with a mass percentage of 28.7% 2 O, 65.7% montmorillonite, 5.6% tantalum oxide were stirred in 20ml (when the montmorillonite was 7.1g) in isopropanol for 24 hours and dried.

[0066] (2) Grind the lumps dried in step (1) into powder, place them evenly in a crucible, and burn them in air at 900° C. for 9 hours with a heating rate of 5° C. / min.

[0067] (3) The powder sample completed by burning paper in step (2) was ball milled 30 times at a speed of 800r / min, each time being 5min, to obtain β-LiAlSi doped with Ta 2 o 6 ,spare.

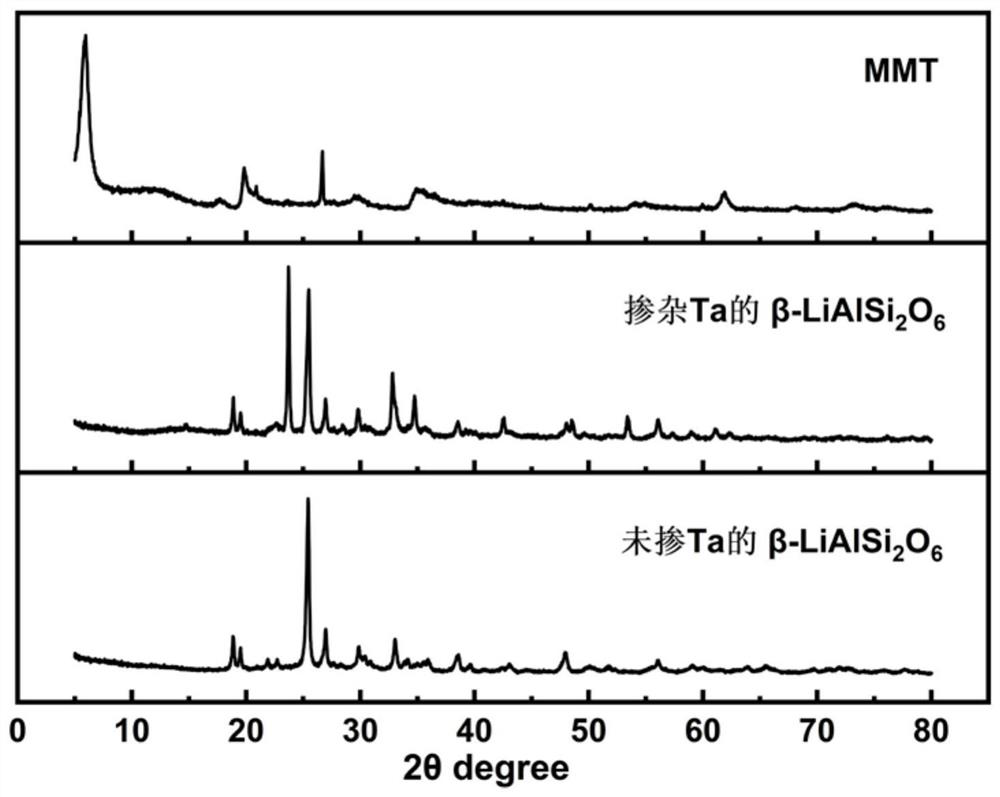

[0068] The Ta-doped β-LiAlSi 2 o 6 See the XRD pattern of figure 1 . figure 1 Among them, MMT is the XRD pattern of montmorillonite. From figure 1 It can be seen that the peaks at 23.7° and 25.48° are Ta-doped β-LiAlSi 2 o 6 The two most obvious characteristic peaks of XRD show that the present invention has successfully prepared Ta-dope...

Embodiment 2

[0096] Referring to the preparation method of Example 1, the composition of the solid electrolyte is changed, and the solid electrolyte is composed of the following components in mass percentage: 65% of the polymer substrate; 25% of the lithium salt; 10% of the additive; wherein, the polymer substrate is Polyvinylidene fluoride (PVDF), lithium salt is LiTFIS, additive is β-LiAlSi doped with Ta 2 o 6 .

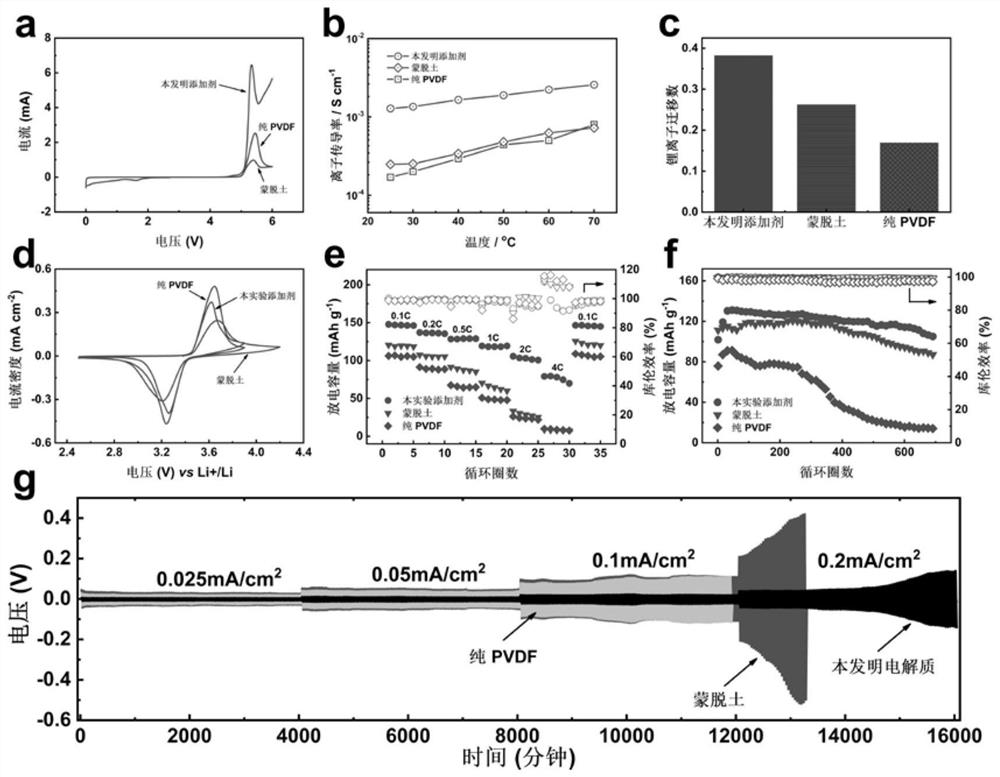

[0097] Using this solid electrolyte to form a battery, the first charge and discharge capacity is 150mAh / g at a rate of 0.1C. According to the picture of the rate performance, the capacity is also close to 150mAh / g at 35 cycles, and the Coulombic efficiency is close to 100%; at a rate of 0.5C , the first cycle capacity is 100mAh / g, but it will quickly rise to 130mAh / g after 2-3 cycles, the capacity is close to 135mAh / g at 40 cycles, and the capacity is still 110mAh / g after 600 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com