Superconducting strip coating and heat treatment integrated multi-channel winding device

A superconducting tape and winding device technology, applied in the usage of superconducting elements, superconducting/high-conducting conductors, superconducting devices, etc., can solve the problems of low production cost and efficiency, strip deformation, strip damage, etc. problem, to achieve the effect of improving work efficiency, shortening time, utilization rate and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

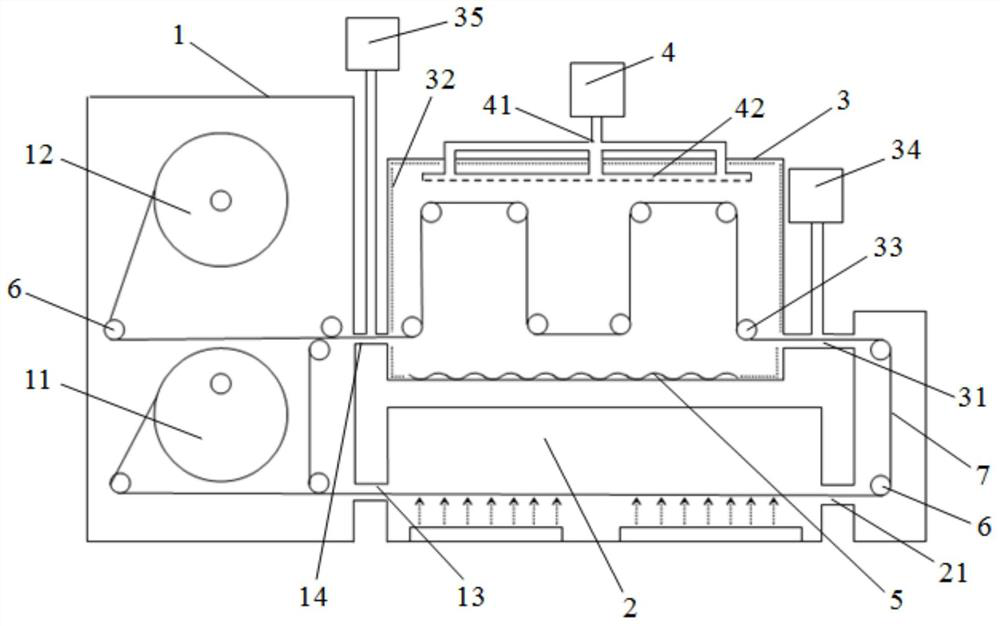

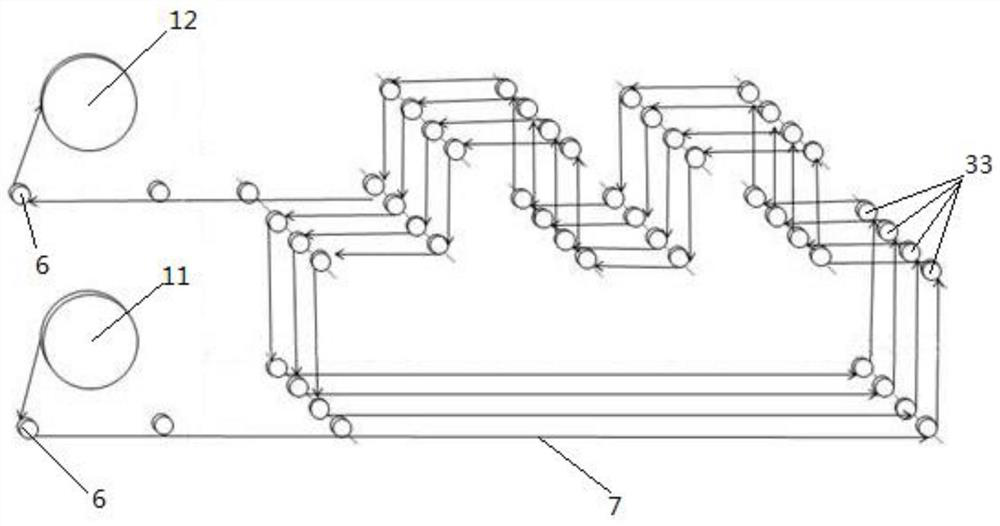

[0031] As attached Figure 1-4 As shown, a multi-track winding device integrating coating and heat treatment of a superconducting tape includes a strip placing chamber 1, a coating chamber 2, an annealing chamber 3, and an aerobic device 4; the strip placing chamber 1 is provided with an unwinding device 11 and a winding device 12; one side of the strip placing chamber 1 is provided with a coating chamber 2 and an annealing chamber 3; the coating chamber 2 is the lower part of the annealing chamber 3; the unwinding An unwinding port 13 is provided at the 11 position of the device to connect the strip placing chamber 1 and the coating chamber 2; the winding device 12 is provided with a winding port 14 to connect the strip placing chamber 1 and the annealing chamber 2; The coating chamber 2 on the opposite side of the reeling mouth 13 is provided with a coating chamber tape outlet 21; the annealing chamber 3 on the opposite side of the winding port 14 is provided with an annealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com