Macromolecular root-resistant waterproof roll and production method thereof

A root puncture-resistant, waterproof membrane technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, building insulation materials, etc., can solve the problems of insufficient reliability and affect the waterproof effect, etc., to ensure Water-repellent effect, excellent flexibility and bonding ability, effect of strengthening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

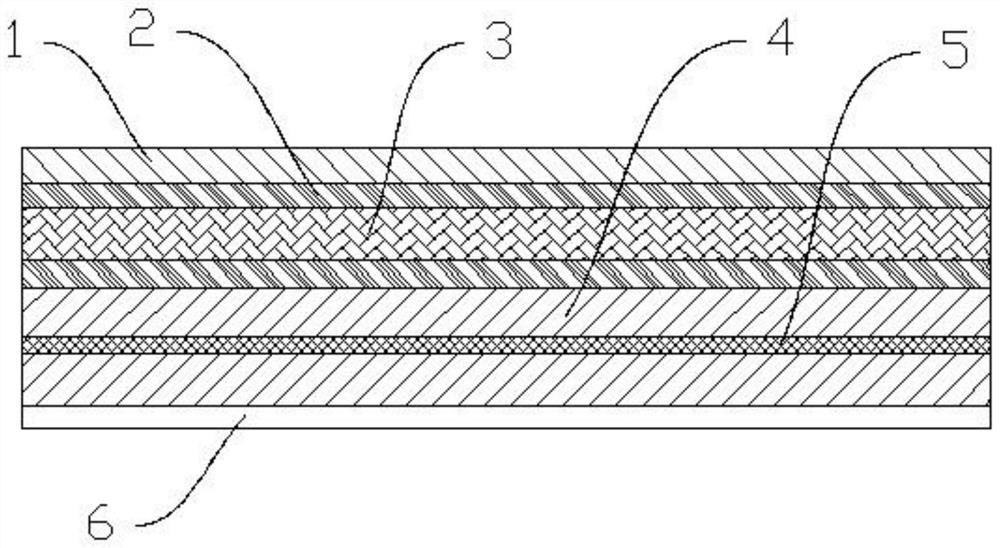

[0027] like figure 1 As shown, the present invention proposes a polymer root-resistant puncture-resistant waterproof membrane, including a release film 6, an adhesive layer 4, and a root-blocking base layer 3 arranged sequentially from bottom to top, and the adhesive layer 4 is also provided inside There is a reinforcing layer 5, the reinforcing layer 5 is used for waterproofing and preventing root puncture, one side of the adhesive layer 4 is closely connected with the root-blocking base layer 3 to form a whole, and the other side is covered by a release film 6 for protection. Tear off the release film 6, and then stick the adhesive layer 4 on the working surface; the root-blocking base layer 3 includes a polymer root-blocking layer, two layers of waterproof layers 2 with a polymer root-blocking layer sandwiched up and down, and a set The protective layer 1 outside the upper waterproof layer 2.

[0028] In a further solution of the present invention, the reinforcing layer 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear load | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com