Movable MEMS large turning angle blazed grating light modulator based on double-layer comb drive

A blazed grating and optical modulator technology, applied in the field of MEMS optical modulators, can solve the problems of tuning frequency (low switching speed, limited tuning ability of optical modulators, small rotation angle of grating bars, etc.) Reliable performance and large rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below.

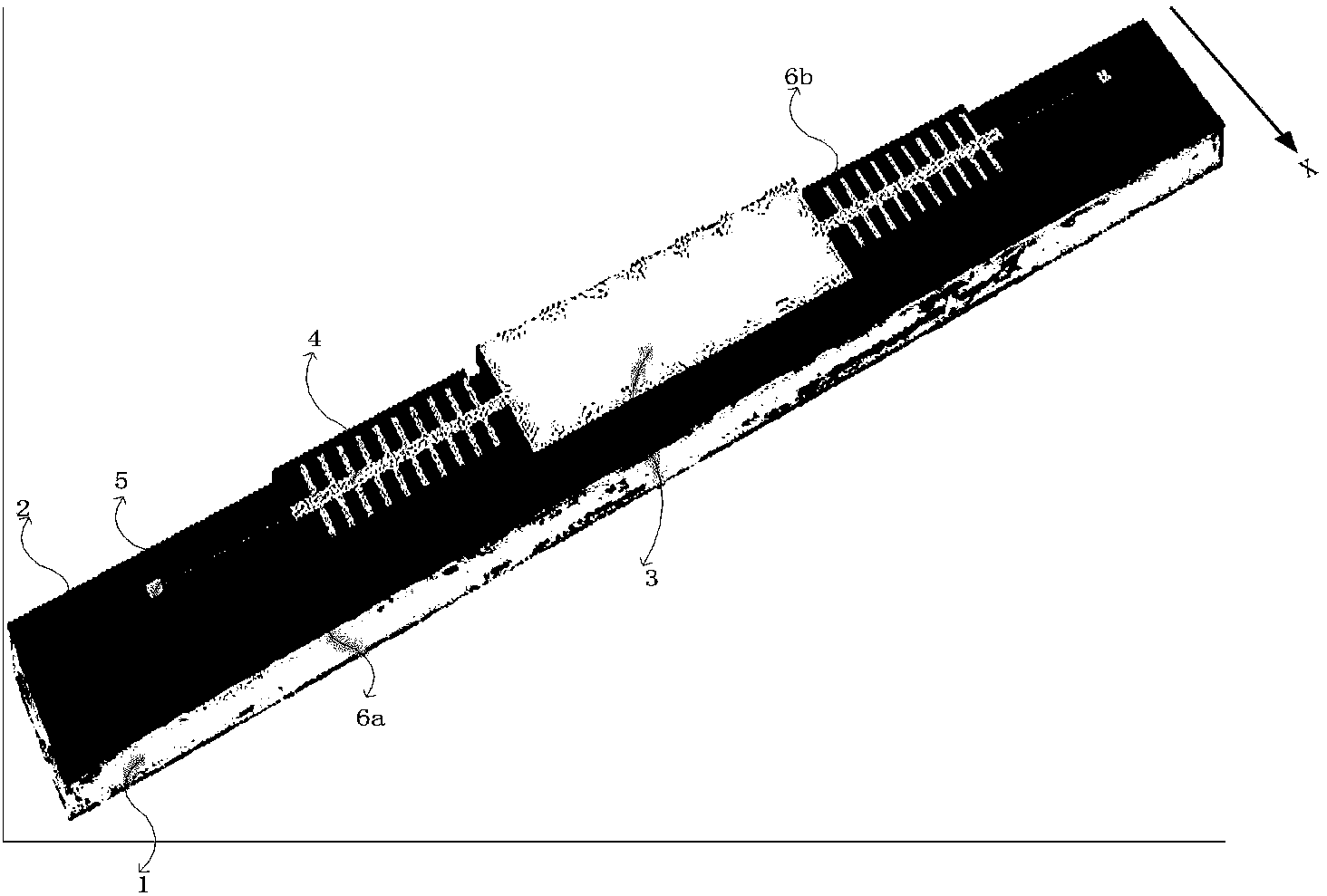

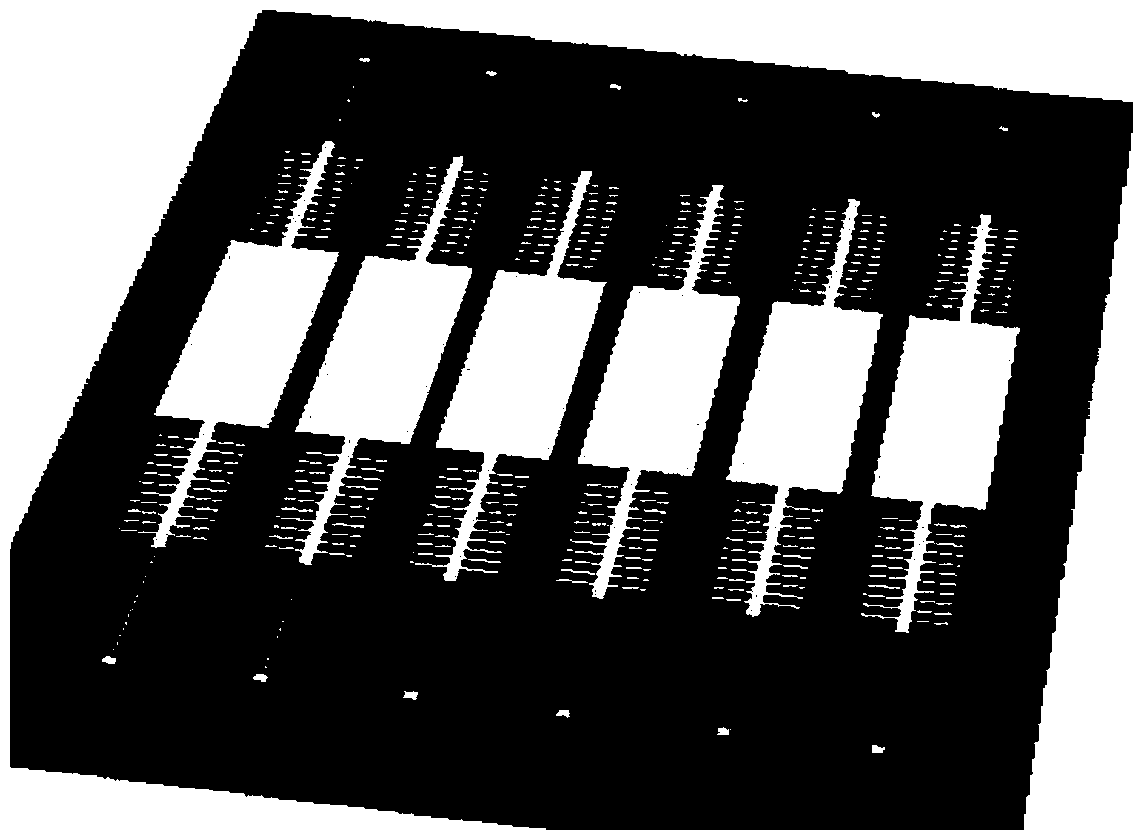

[0025] see figure 1 In this embodiment, the silicon substrate 1 of the double-layer comb driven MEMS large-rotation-angle movable blazed grating optical modulator and the insulating layer 2 disposed on the silicon substrate 1, the grating mirror surface 3 is suspended and supported on the insulating layer 2 by torsion beams Above, the torsion beam is composed of movable teeth 4 and pillars 5, electrodes are arranged on the movable teeth 4, one end of the movable teeth 4 is fixed on the insulating layer 2 through the pillars 5, and the other end of the movable teeth 4 is fixed to the grating mirror 3 connection, the movable teeth are two, fixedly connected with the two ends of the grating mirror 3 respectively, the movable teeth 4 and the fixed teeth 6 form a comb driver, wherein the fixed teeth 6 are fixed on the substrate 1, and electrodes are arranged on it , there are two fixed teeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com