High-performance colored cementing material and preparation method thereof

A technology of colored glue and binder, applied in building insulation materials, building components, buildings, etc., can solve the problems of poor aging resistance, easy falling off of aggregate particles, loose road surface, etc., to improve driving quality and enhance dispersion performance , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

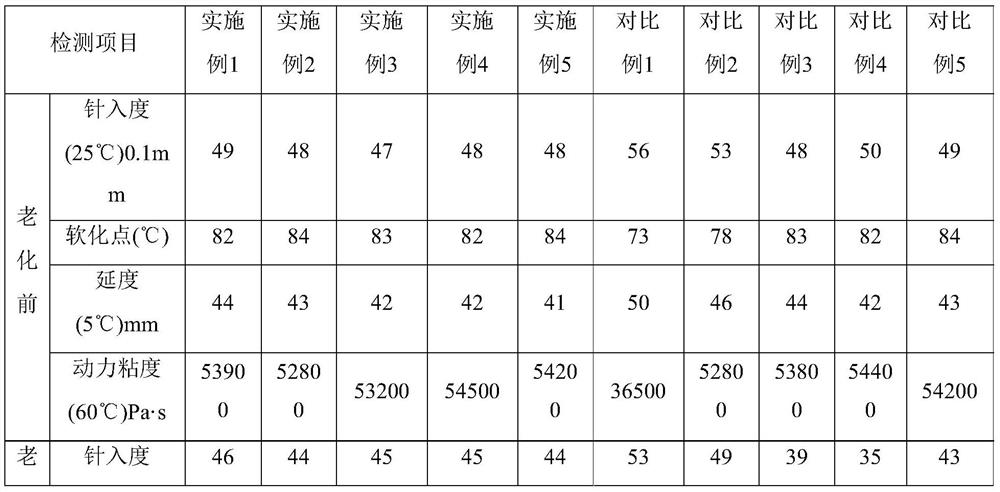

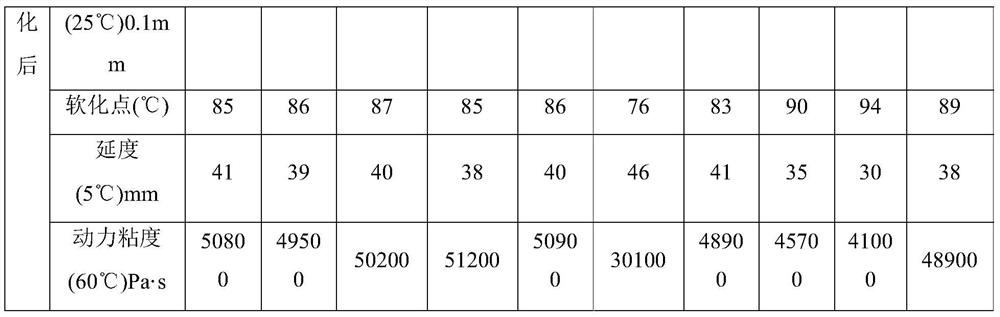

Examples

Embodiment 1

[0038] (1) Heat 40 parts of rubber oil to 130°C in a synthetic tank, keep it for 30 minutes and then raise the temperature to 150°C, add 50 parts of C 9The petroleum resin was continuously stirred at a constant speed of 800r / min for 30min, and the temperature was raised to 170°C, and then 5 parts of SBS modifier was added and continuously stirred until the modified asphalt binder was completely melted.

[0039] (2) Add 5 parts of rosin resin and 0.5 part of modified nano-titanium dioxide particles to 50 parts of modified asphalt binder, add while stirring, and stir for 20 minutes to obtain high-viscosity modified asphalt binder;

[0040] (3) Heat the high-viscosity modified asphalt binder to 160°C, add 4 parts of self-crosslinking polyacrylic acid resin after high-speed shearing or colloid mill grinding for 10 minutes, and continue high-speed shearing or colloid mill grinding for 5 minutes;

[0041] (4) Place the sheared or ground cement in a growth tank at 150°C for 10 minute...

Embodiment 2

[0043] (1) Heat 70 parts of rubber oil to 140°C in a synthetic tank, keep it for 30 minutes and then raise the temperature to 155°C, add 90 parts of C 9 The petroleum resin was continuously stirred at a constant speed of 800r / min for 30min, the temperature was raised to 170°C, and then 8 parts of SBR modifier was added and continuously stirred until the modified asphalt binder was obtained until the melting was complete.

[0044] (2) Add 10 parts of rosin resin and 1 part of modified nano-titanium dioxide particles to 60 parts of modified asphalt binder, add while stirring, and stir for 15 minutes to obtain high-viscosity modified asphalt binder;

[0045] (3) Heat the high-viscosity modified asphalt binder to 170°C, add 6 parts of self-crosslinking unsaturated polyester resin after high-speed shearing or colloid mill grinding for 15 minutes, and continue high-speed shearing or colloid mill grinding for 8 minutes;

[0046] (4) Place the sheared or ground cement in a growth tank...

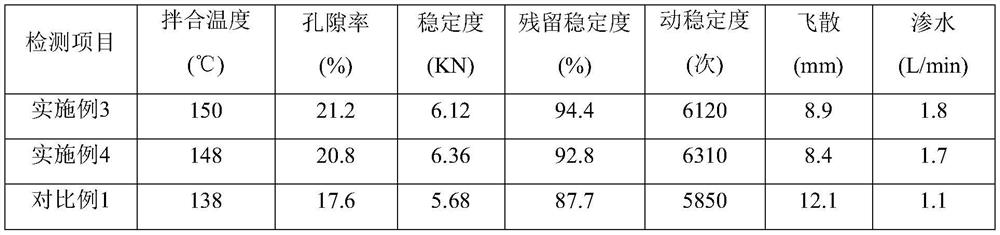

Embodiment 3

[0048] (1) Heat 100 parts of rubber oil to 150°C in a synthesis tank, keep it for 30 minutes and then raise the temperature to 160°C, add 80 parts of C 5 The petroleum resin was continuously stirred at a constant speed of 800r / min for 30min, the temperature was raised to 170°C, and then 12 parts of SBS modifier was added and continuously stirred until the modified asphalt binder was obtained until it was completely melted.

[0049] (2) Add 15 parts of rosin resin and 1.5 parts of modified nano-titanium dioxide particles to 70 parts of modified asphalt binder, add while stirring, and stir for 10 minutes to obtain a high-viscosity modified asphalt binder;

[0050] (3) Raise the temperature of the high-viscosity modified asphalt binder to 180°C, add 8 parts of self-crosslinking silicone resin after high-speed shearing or colloid mill grinding for 10 minutes, and continue high-speed shearing or colloid mill grinding for 10 minutes;

[0051] (4) Place the sheared or ground cement i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com