Hollow hemisphere plane turning device

A hollow hemisphere and plane technology, which is applied in metal processing mechanical parts, maintenance and safety accessories, metal processing, etc., can solve the problems of low turning efficiency and poor product precision, and achieve high work efficiency, accurate and convenient clamping and positioning, The effect of high turning precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

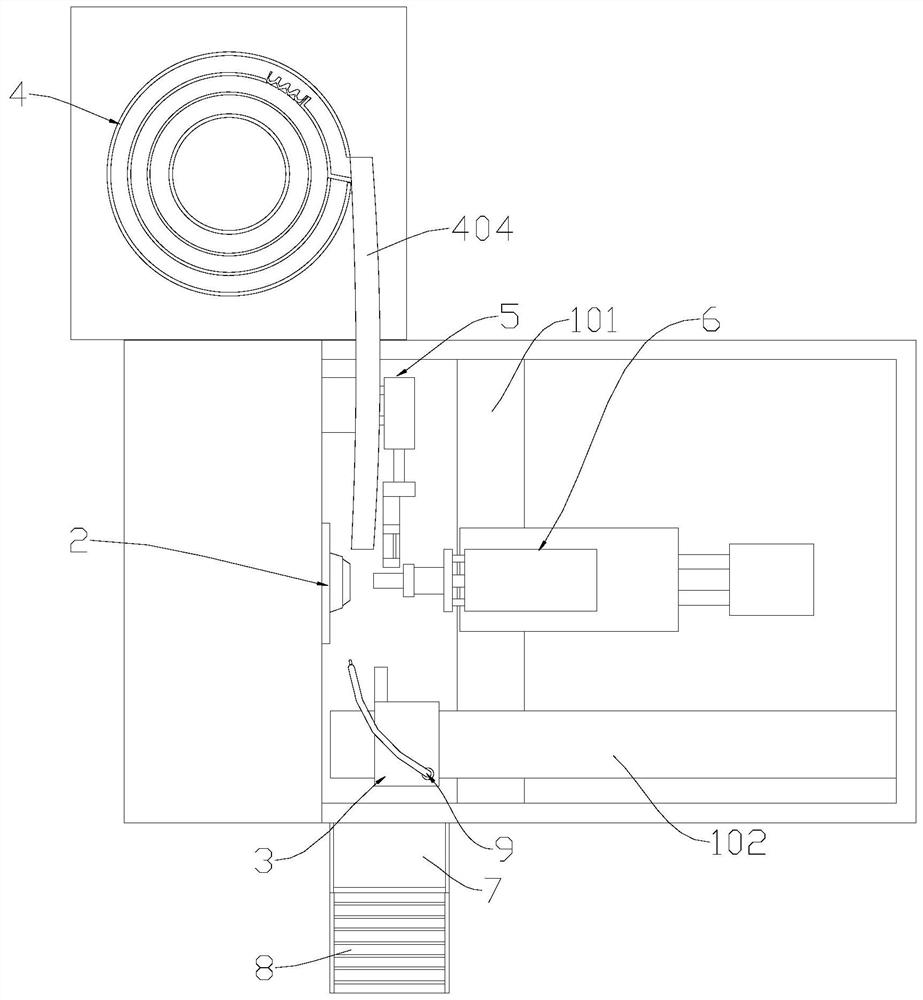

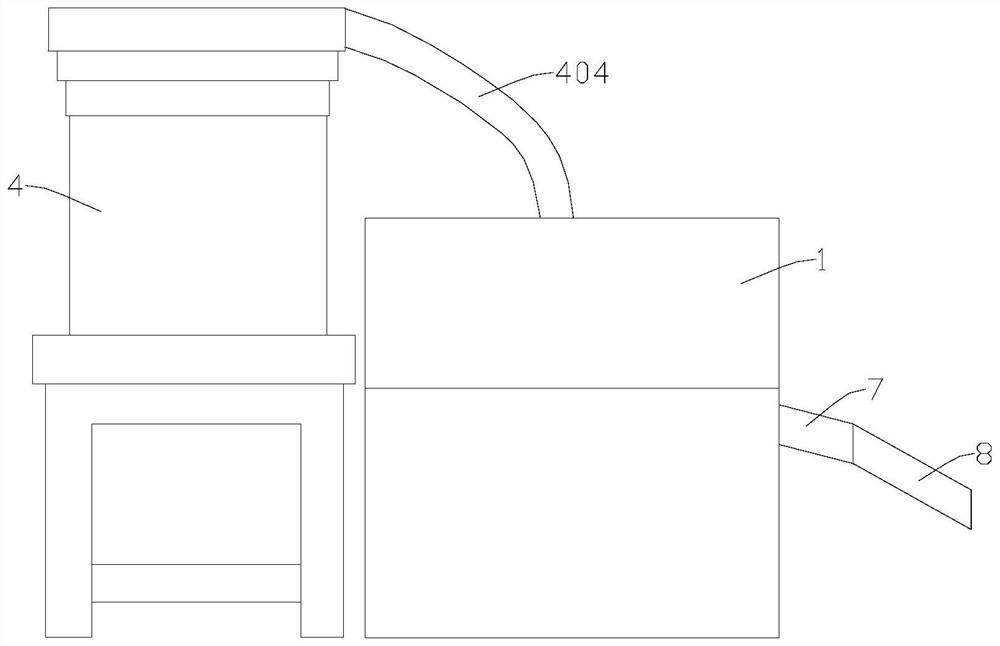

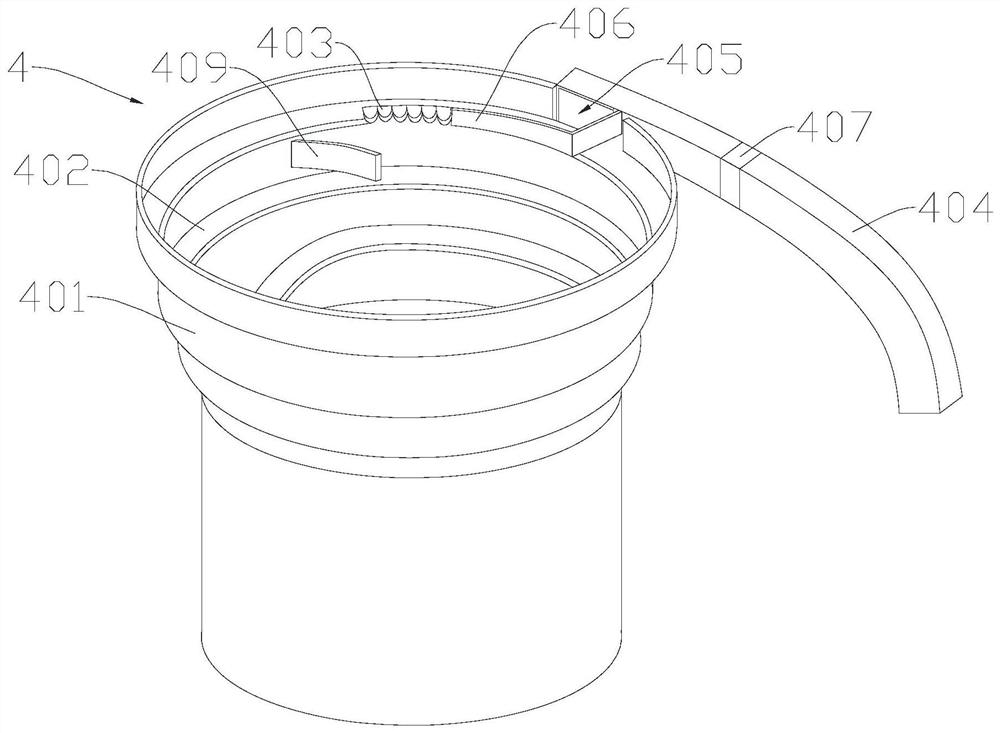

[0046] Please refer to Figure 1-8 , this embodiment provides a hollow hemispherical plane turning device, including a bed 1, on which a fixture 2 and a cutting mechanism 3 are arranged horizontally from left to right, and an automatic feeding mechanism and a positioning mechanism 6, the The automatic feeding mechanism includes a feeding device 4 and a clamping device 5, the feeding device 4 is used to transport the hollow hemisphere to the clamping device 5, and the clamping device 5 is used to clamp the hollow hemisphere to the clamp 2, the The positioning mechanism 6 is used to accurately clamp the hollow hemisphere in the fixture 2 .

[0047] The feeding device 4 transports the hollow hemisphere to the clamping device 5, the clamping device 5 clamps the hollow hemisphere and sends it to the fixture 2, and the positioning mechanism 6 accurately clamps the hollow hemisphere in the fixture 2, and the clamping and positioning are accurate and convenient , high turning precisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com