Numerical control turning machining center

A machining center and turning technology, which is applied in the field of turning processing, can solve the problems of cutter deviation and damage, reduce the processing efficiency of equipment, and cannot accurately cut the knife, etc., and achieve the effect of improving machining accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

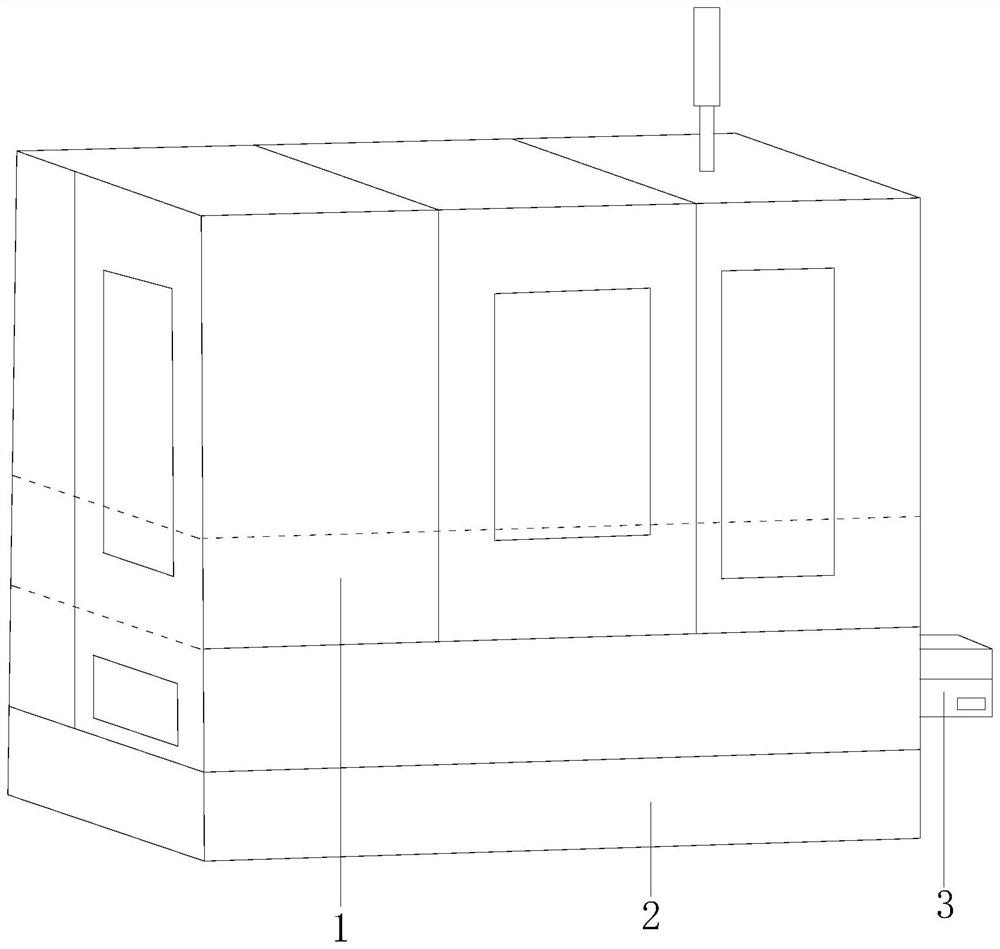

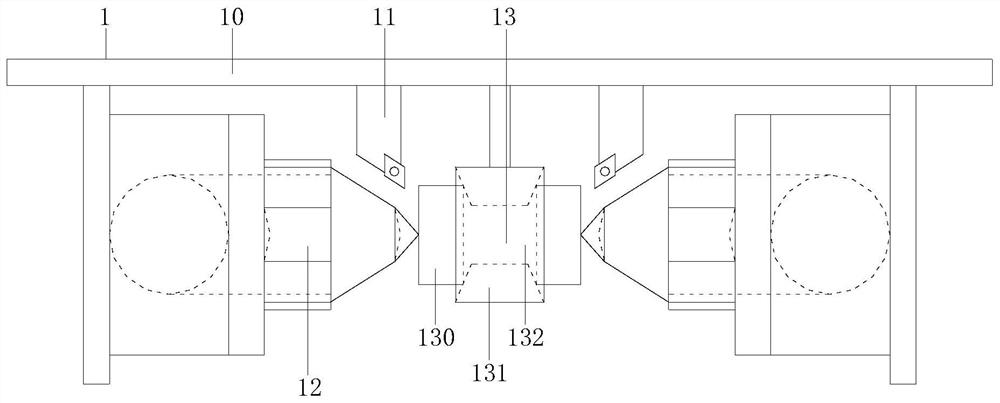

[0024] Example 1 see Figure 1-3 , the present invention provides a technical solution for a numerical control turning machining center: its structure includes a turning device 1, a turning machine 2, and a console 3, the turning device 1 is installed on the turning machine 2, and the turning machine 2 is locked with the console 3 And the two are electrically connected, the turning device 1 is composed of a mounting frame 10, a turning knife 11, a side end feeding device 12, and a middle part feeding device 13, the mounting frame 10 is connected to the turning blade 11, and the mounting frame 10 is locked with the side end material fixing device 12 and the middle part material fixing device 13, and the side end material fixing device 12 fixes the materials located at both ends of the middle part material fixing device 13, and the middle part material fixing device 13 includes material level 130, internal setting device 131 and middle pile 132, the material level 130 is install...

Embodiment 2

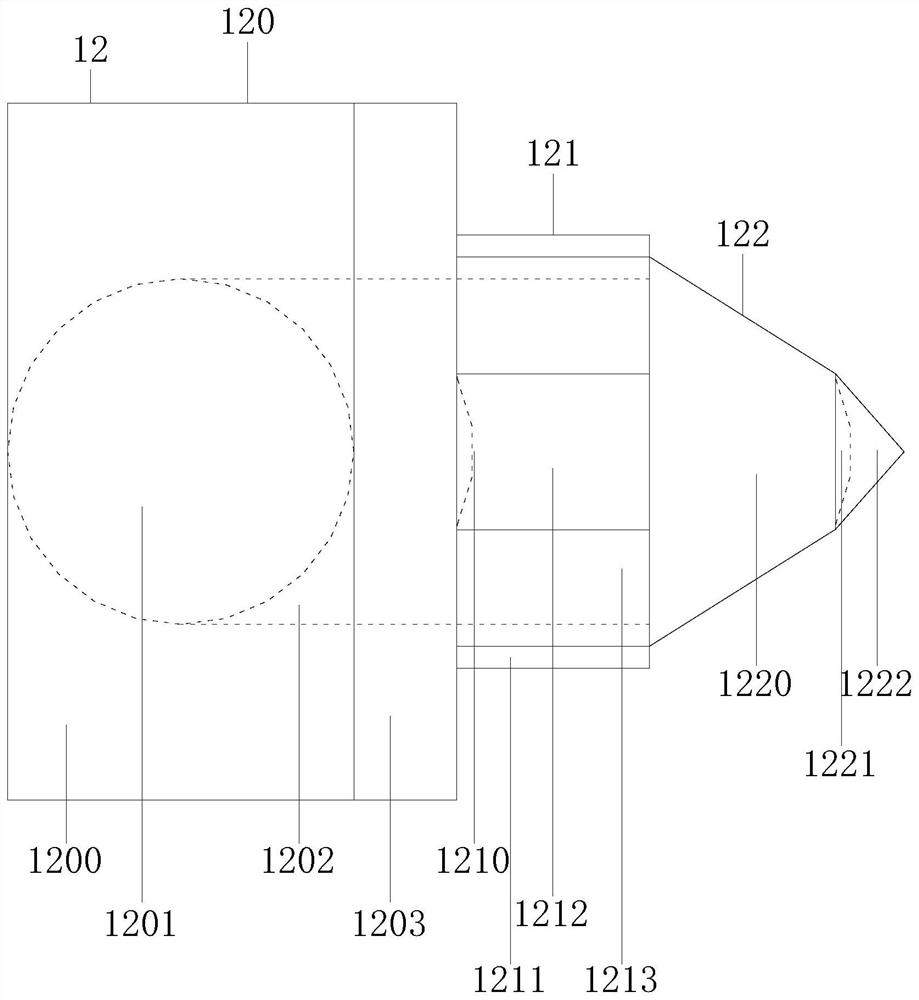

[0026] Example 2 see Figure 4 , 5 , the present invention provides a technical solution for a numerical control turning machining center: the internal fixer 131 includes an internal fixed frame structure 1310 and an internal fixed movable structure 1311, and the internal fixed movable structure 1311 adjusts the movement of materials and strengthens the fixing of materials. The internal fixed frame structure 1310 is installed and connected with the internally fixed movable structure 1311. The internally fixed frame structure 1310 includes a fixed structure frame 41 and a device shaft 42. The fixed structure frame 41 is connected to the device shaft 42. Block 50, middle fixed block 51, movable fixed material rack 52, inner fixed device shaft 53, described movable fixed block 50 is connected with middle fixed block 51 tracks, and described movable fixed block 50 comprises fixed material arc frame 500, arc frame track 501 , the fixed material arc frame 500 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com