Water electrolysis catalyst based on high catalytic activity and crystallinity RuTe2 and preparation method thereof

A technology with high catalytic activity and crystallinity, applied in the field of electrolysis of water, can solve the problems of harsh reaction conditions, poor catalytic performance, poor dispersion of electrolytic water catalysts, etc., and achieve the effect of excellent catalytic activity and good charge density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] High catalytic activity and crystalline water electrolysis catalyst RuTe 2 Preparation of / Gr-400 (50:2:2): Disperse 50mg of graphene into a 100mL beaker containing 50mL of ethylene glycol, add 36.9mg of sodium tellurite and 43.6mg of ruthenium chloride in sequence, and stir magnetically at room temperature until the solution Mix evenly, use a solid-liquid microwave synthesis extractor, set the parameter power to 800W, and set the time for 3min, wash the mixture with deionized water, filter and dry to obtain the precursor material. Take 30mg of precursor material, put it into the crucible, under continuous N 2 Under the atmosphere, set the heating rate to 2°C min -1 , the holding time is 2h, heat treatment at 400°C, after cooling to room temperature, the sample is taken out and ground to obtain RuTe based on high catalytic activity and crystallinity 2 Catalyst for electrolysis of water, denoted as RuTe 2 / Gr-400(50:2:2).

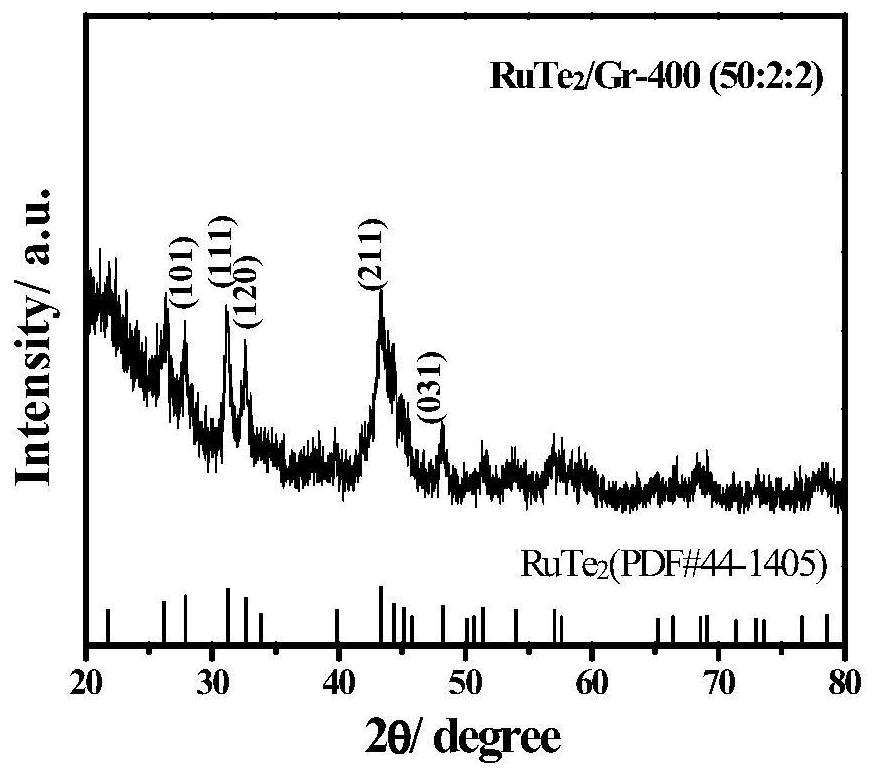

[0052] figure 1 High catalytic activity an...

Embodiment 2

[0058] High catalytic activity and crystalline water electrolysis catalyst RuTe 2 / CNT-400 (50:2:2): Disperse 50mg of carbon nanotubes into a 100mL beaker containing 50mL of ethylene glycol, add 36.9mg of sodium tellurite and 43.6mg of ruthenium chloride in turn, and stir magnetically at room temperature until The solution was mixed evenly, using a solid-liquid microwave synthesis extraction instrument, setting the parameter power to 800W, and the time was 3min, using deionized water to wash the mixture, filtering and drying to obtain the precursor material (RuTe 2 / CNT). Take 30mgRuTe 2 / CNT material, placed in the crucible, under continuous N 2 Under the atmosphere, set the heating rate to 2°C min -1 , the holding time is 2h, heat treatment at 400°C, after cooling to room temperature, the sample is taken out and ground to obtain a RuTe based on high crystallinity 2 Catalyst for electrolysis of water, denoted as RuTe 2 / CNT-400(50:2:2).

[0059] Figure 6 For the high ...

Embodiment 3

[0065] High catalytic activity and crystalline water electrolysis catalyst RuTe 2 Preparation of / Gr-300 (50:2:2): Disperse 50mg of graphene into a 100mL beaker containing 50mL of ethylene glycol, add 36.9mg of sodium tellurite and 43.6mg of ruthenium chloride in sequence, and stir magnetically at room temperature until the solution Mix evenly, use a solid-liquid microwave synthesis extractor, set the parameter power to 800W, and set the time for 3min, wash the mixture with deionized water, filter and dry to obtain the precursor material. Take 30mg of precursor material, put it into the crucible, under continuous N 2 Under the atmosphere, set the heating rate to 2°C min -1 , the holding time is 2h, heat treatment at 300°C, after cooling to room temperature, the sample is taken out and ground to obtain RuTe based on high catalytic activity and crystallinity 2 Catalyst for electrolysis of water, denoted as RuTe 2 / Gr-300(50:2:2).

[0066] Figure 11 High catalytic activity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com