Milk, milk production equipment and production process

A technology for producing equipment and milk, applied in the field of milk production equipment and production technology, and milk, can solve the problems of not easy to disassemble and clean, not easy to mix evenly in the mixing box, large consumption, etc., and achieve the effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

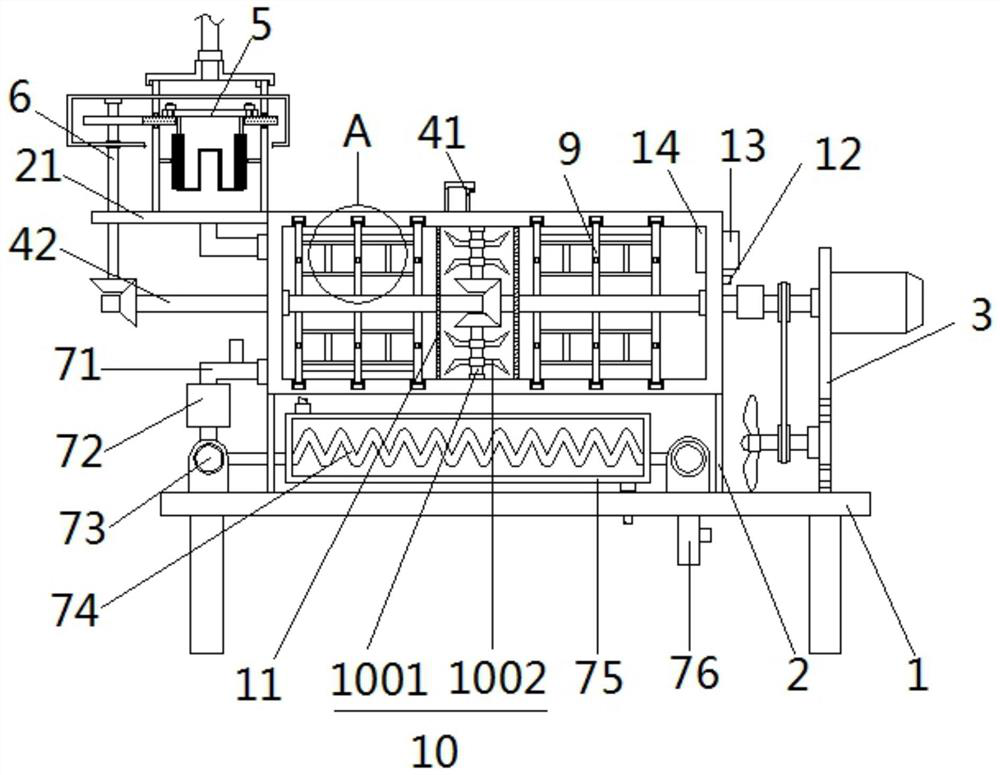

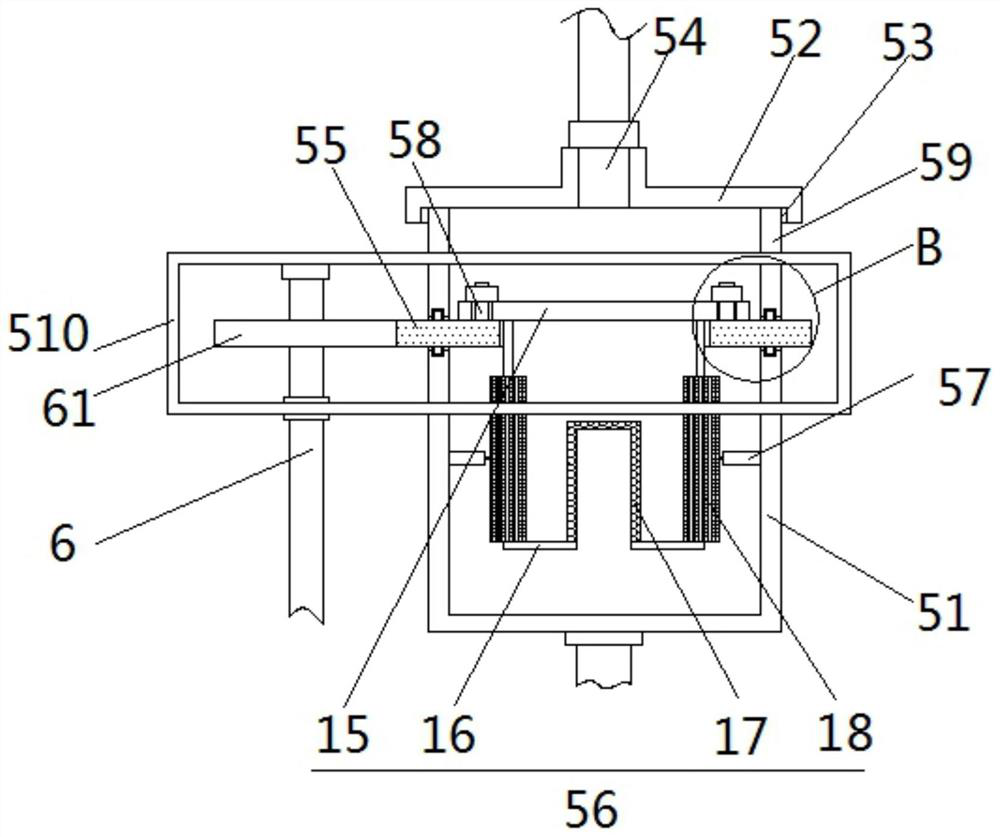

[0036] as attached figure 1 To attach Figure 9 Shown: a milk, milk production equipment and production process, including a support base 1, a heat dissipation support plate 2, a fixed plate 3, a mixing box 4, a filter device 5, the front and rear sides of the support base 1 are fixed vertically and fixedly connected with heat dissipation A mixing box 4 is fixedly connected between the support plate 2 and the top of the heat dissipation support plate 2, and a connecting shaft 42 is rotatably connected between the center positions of the left and right sides of the mixing box 4, and the left side of the connecting shaft 42 extends to the outside of the mixing box 4 and is fixedly connected with a Bevel gear, the central position of the connecting shaft 42 is fixedly connected with a bevel gear, the left and right sides of the central position of the mixing box 4 are fixedly connected with a spacer 11, and the top of the mixing box 4 is provided with an adding pipe 41 at the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com