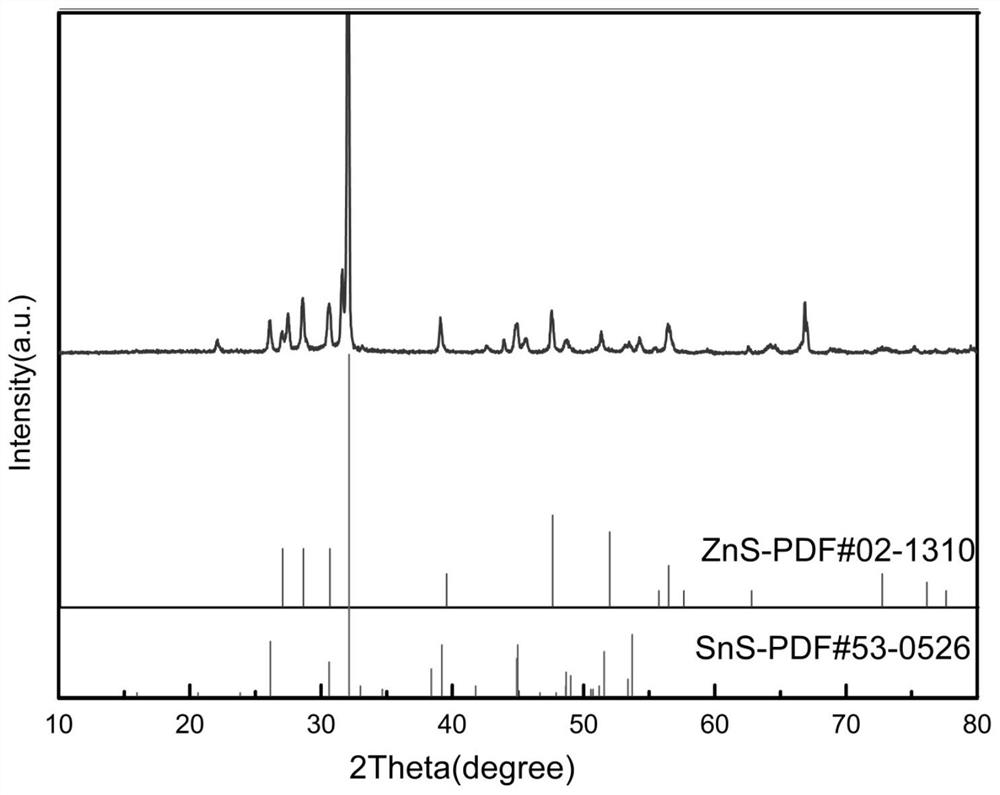

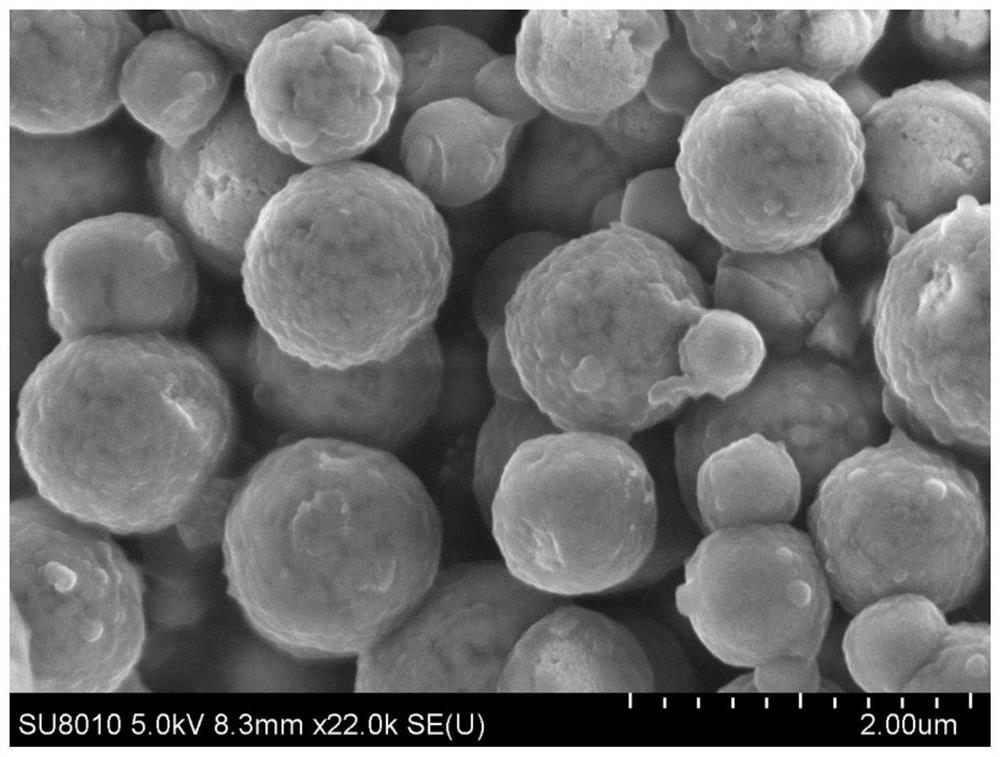

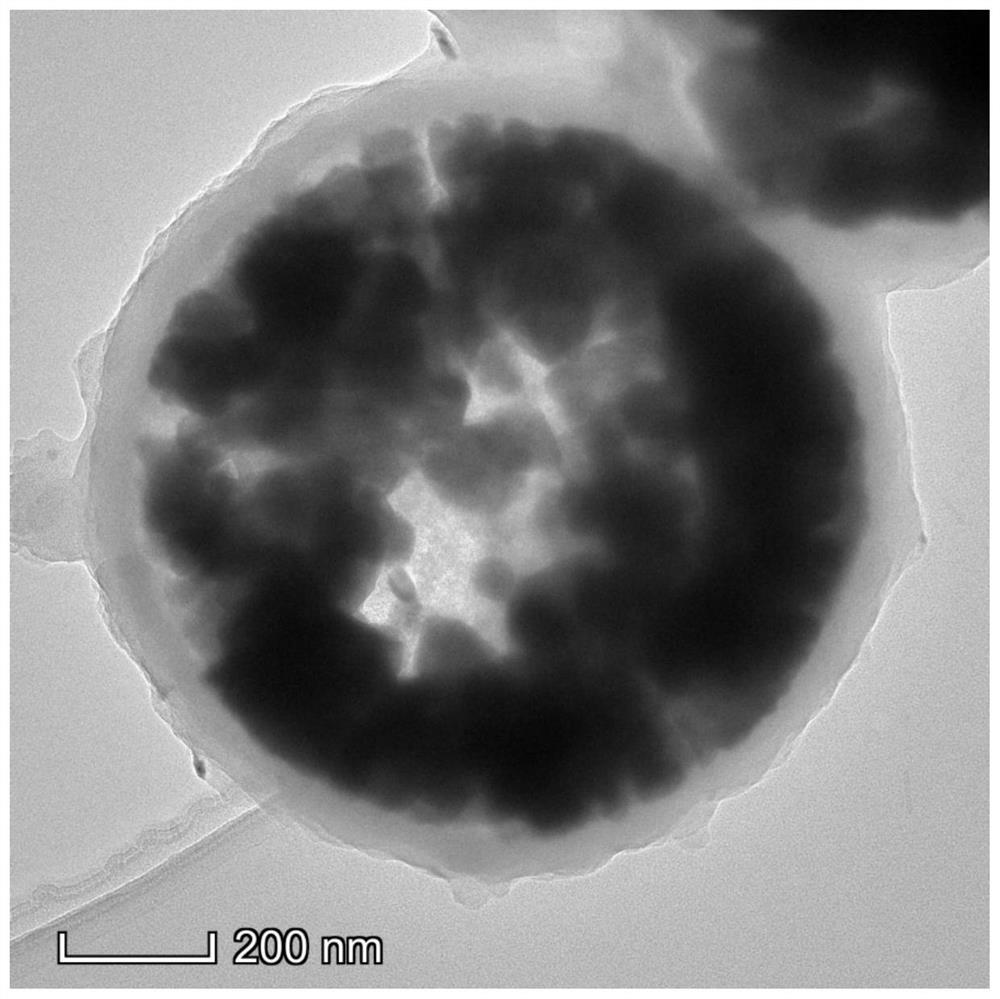

A kind of zns/sns@nc hollow microsphere negative electrode material for lithium ion/sodium ion battery negative electrode and preparation method thereof

A technology for sodium ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as the need to improve the commercial application value, the first coulomb efficiency and the capacity retention rate after the cycle is not very good, etc. Suitable for mass production, improved electronic conductivity, high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of ZnS / SnS@NC hollow microsphere negative electrode material for lithium ion / sodium ion battery negative electrode, comprising the following steps:

[0032] (1) Take 0.284g NaSnO 3 ·2H 2 O was dissolved in 10ml of deionized water, and an aqueous solution of sodium alginate was added as solution A, so that the concentration of sodium alginate in solution A was 0.8g / L, and 0.251g (CH 3 COO) 2 Zn·2H 2 O is dissolved in 2ml of deionized water, and an excess of concentrated ammonia water with a concentration of 25% is added as liquid B. The ammonia molecules in the concentrated ammonia water are combined with (CH) 3 COO) 2 Zn·2H 2 Zn in O 2+ The molar ratio of 4.1:1 is favorable for the formation of Zn(NH 3 ) 4 2+ ; Mix the A and B liquids together and put them in the autoclave, keep at 150°C for 6h to obtain ZnSn(OH) 6 ;

[0033] (2) Weigh 0.2 g of ZnSn(OH) obtained in step (1) 6 and 10 mg of sodium dodecyl sulfate dissolved in 60 ml of deio...

Embodiment 2

[0040] A preparation method of ZnS / SnS@NC hollow microsphere negative electrode material for lithium ion / sodium ion battery negative electrode, comprising the following steps:

[0041] (1) Take 0.284g NaSnO 3 ·2H 2 O was dissolved in 10ml of deionized water, and an aqueous solution of sodium alginate was added as liquid A, so that the concentration of sodium alginate in liquid A was 1.0g / L, and 0.276g (CH 3 COO) 2 Zn·2H 2 O is dissolved in 2ml of deionized water, and an excess of concentrated ammonia water with a concentration of 25% is added as liquid B. The ammonia molecules in the concentrated ammonia water are combined with (CH) 3 COO) 2 Zn·2H 2 Zn in O 2+ The molar ratio of 4.2:1 is favorable for the formation of Zn(NH 3 ) 4 2+ ; Mix the A and B liquids together and put them in the autoclave, keep at 155°C for 5.5h to obtain ZnSn(OH) 6 ;

[0042] (2) Weigh 0.2 g of ZnSn(OH) obtained in step (1) 6 and 10 mg of sodium dodecyl sulfate dissolved in 60 ml of deioni...

Embodiment 3

[0048] A preparation method of ZnS / SnS@NC hollow microsphere negative electrode material for lithium ion / sodium ion battery negative electrode, comprising the following steps:

[0049] (1) Take 0.284g NaSnO 3 ·2H 2 O was dissolved in 10ml of deionized water, and an aqueous solution of sodium alginate was added as liquid A, so that the concentration of sodium alginate in liquid A was 1.1 g / L, and 0.428 g (CH 3 COO) 2 Zn·2H 2 O is dissolved in 2ml of deionized water, and an excess of concentrated ammonia water with a concentration of 25% is added as liquid B. The ammonia molecules in the concentrated ammonia water are combined with (CH) 3 COO) 2 Zn·2H 2 Zn in O 2+ The molar ratio of 5:1 is favorable for the formation of Zn(NH 3 ) 4 2+ ; Mix the A and B liquids together and put them in the autoclave, keep at 160°C for 5h to obtain ZnSn(OH) 6 ;

[0050] (2) Weigh 0.3 g of ZnSn(OH) obtained in step (1) 6 and 10 mg of sodium dodecyl sulfate dissolved in 60 ml of deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com