Preparation method of nanoscale PET material applied to lithium battery non-woven fabric diaphragm

A non-woven diaphragm and nano-scale technology, which is applied in the field of preparation of nano-scale PET materials, can solve the problems of reducing the processing cost of nano-scale PET materials and popularizing the application of nano-scale fibers to non-woven diaphragms of lithium batteries, etc. Good dispersion effect, reduce processing cost, accelerate the effect of rapid prototyping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

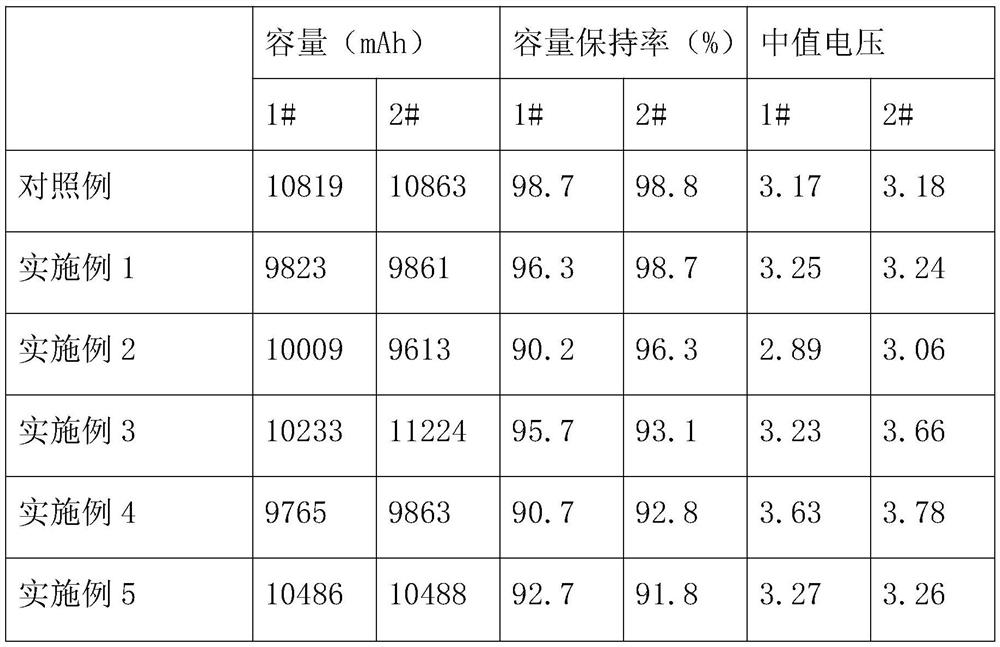

Examples

Embodiment 1

[0025] This embodiment provides a method for preparing a nanoscale PET material applied to a lithium battery non-woven diaphragm, which specifically includes the following steps:

[0026] S1: Weigh 50 parts by weight of ordinary PET fiber material, and soak the ordinary PET fiber material in nano-silica sol for 30 minutes;

[0027] S2: After the infiltration is completed, evenly apply the nano-silica sol on the surface of the ordinary PET fiber material by roller coating. After the roller coating is completed, the ordinary PET fiber material is taken out and dried to form a A layer of silicone gel, which is a mixture of PET fiber materials;

[0028] S3: Add the PET fiber material mixture prepared in S2 into the polymerization reactor, then add organic solvent and inorganic particles to the reactor in turn, the ratio of the organic solvent to the inorganic particles is 10:1, and heat up to 60 ℃, last for 3h;

[0029] S4: After the heating is completed, cool to 20°C, then add ...

Embodiment 2

[0040] This embodiment provides a method for preparing a nanoscale PET material applied to a lithium battery non-woven diaphragm, which specifically includes the following steps:

[0041] S1: Weigh 70 parts by weight of ordinary PET fiber material, and soak the ordinary PET fiber material in nano-silica sol for 35 minutes;

[0042] S2: After the infiltration is completed, evenly apply the nano-silica sol on the surface of the ordinary PET fiber material by roller coating. After the roller coating is completed, the ordinary PET fiber material is taken out and dried to form a A layer of silicone gel, which is a mixture of PET fiber materials;

[0043] S3: Add the PET fiber material mixture prepared in S2 into the polymerization reaction kettle, and then add organic solvent and inorganic particles to the reaction kettle in turn. The ratio of the organic solvent to the inorganic particles is 11:1, and the temperature is raised to 62 ℃, last for 4h;

[0044] S4: After the heating...

Embodiment 3

[0055] This embodiment provides a method for preparing a nanoscale PET material applied to a lithium battery non-woven diaphragm, which specifically includes the following steps:

[0056] S1: Weigh 80 parts by weight of ordinary PET fiber material, and soak the ordinary PET fiber material in nano-silica sol for 40 minutes;

[0057] S2: After the infiltration is completed, evenly apply the nano-silica sol on the surface of the ordinary PET fiber material by roller coating. After the roller coating is completed, the ordinary PET fiber material is taken out and dried to form a A layer of silicone gel, which is a mixture of PET fiber materials;

[0058] S3: Add the PET fiber material mixture prepared in S2 into the polymerization reactor, and then add organic solvent and inorganic particles to the reactor in turn. The ratio of the organic solvent to the inorganic particles is 12:1, and the temperature is raised to 65 ℃ for 4 hours;

[0059] S4: After the heating is completed, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com