Methods for callus suspension culture and protoplast separation of camellia oleifera

A suspension culture, protoplast technology, applied in biochemical equipment and methods, tissue culture, cell culture medium, etc., can solve the problems of extensive cultivation management, uneven quality of camellia oleifera varieties, lack of resistant varieties, etc., and achieve easy suspension cell lines. , complete shape, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

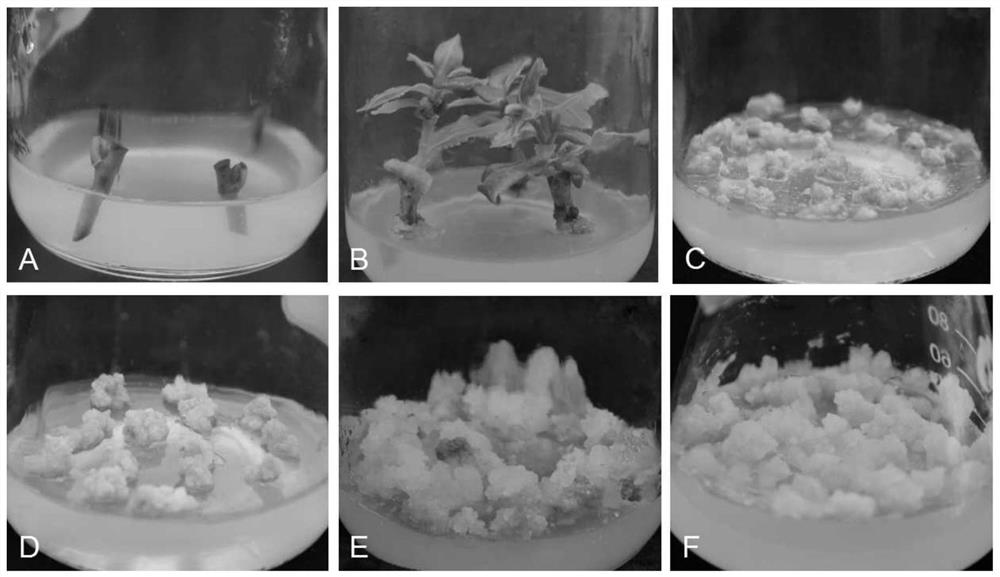

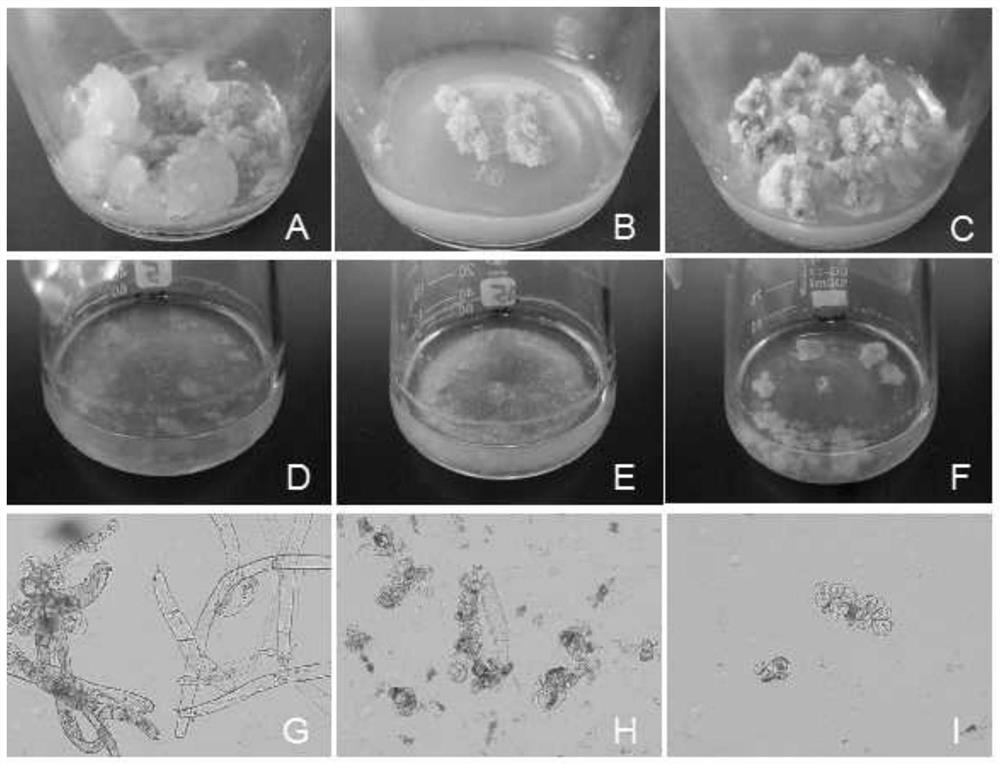

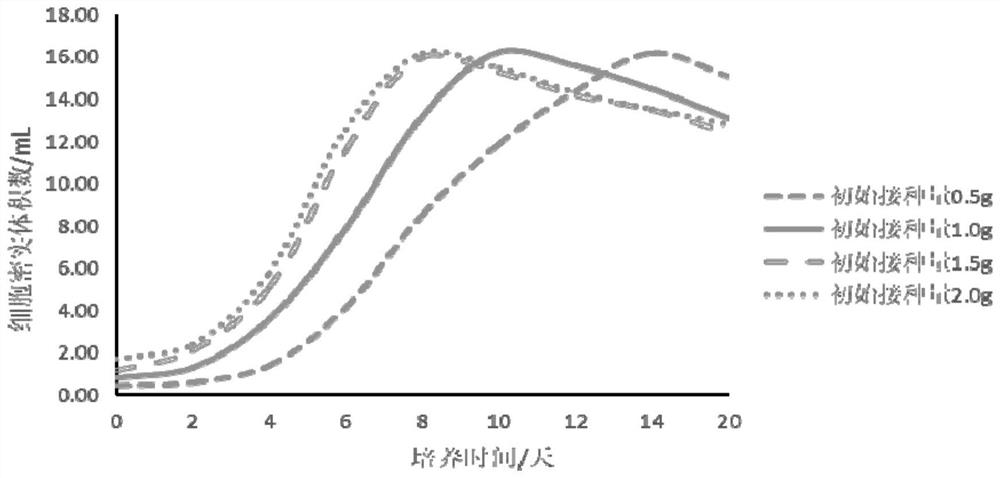

[0033] (1) Collect the half-lignified 5-7cm long stems of ‘Huashuo’ Camellia oleifera in the sunny morning between March and May, remove the leaves, rinse with tap water for 20 minutes, and drain. In the ultra-clean workbench, wash twice with sterile water, then disinfect with 75% (v / v) alcohol for 30 seconds, and then use 0.1% (m / v) HgCl 2 The solution was sterilized for 15 minutes, and finally washed with sterile water for 4 to 5 times, the water on the surface of the stem section was blotted with filter paper, cut into 2-3 cm long single-bud stem sections with a sterile blade, and inoculated into the induction medium for induction. After cultivating for 5 days at a temperature of 28°C and in the dark, transfer to light conditions (light intensity is 2000lx, light time 16h) for cultivation, and after 30 to 40 days, compact calluses are induced at the base of the stem segment (see figure 1 -B). Described induction medium is the MS medium that contains 30g / L sucrose, 7g / L aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com