A kind of plant-based soft capsule rubber, preparation method and application thereof

A technology of soft capsules and rubber skins, which is used in capsule delivery, medical preparations with non-active ingredients, pharmaceutical formulations, etc., to achieve the effects of excellent anti-aging ability, improved wettability, and reduced crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

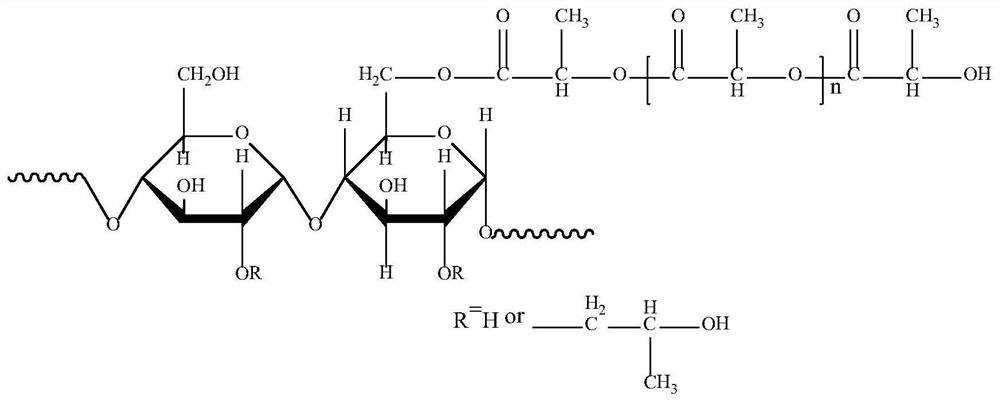

[0075] Example 1: A plant-based softgel rubber:

[0076] The present embodiment provides a kind of plant-based soft capsule rubber, and its specific components and contents thereof include:

[0077]

[0078]

[0079] The degree of substitution of the hydroxypropyl starch is 0.4, and

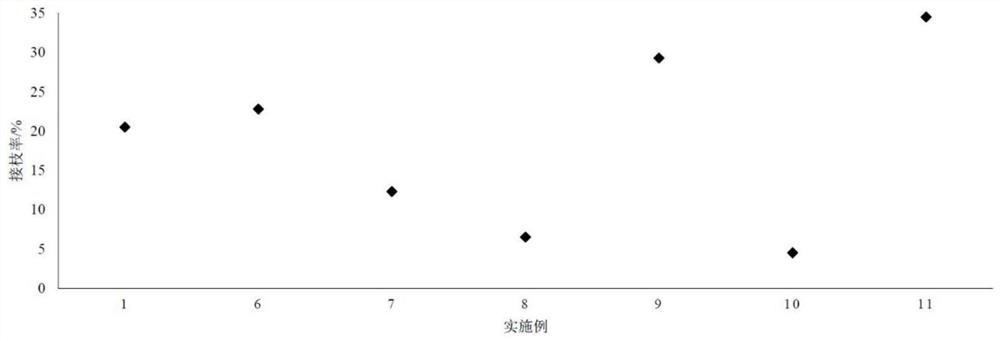

[0080] The grafting ratio of lactic acid to hydroxypropyl starch is 21%.

[0081] The soft capsule rubber described in this embodiment is specifically prepared through a method comprising the following steps:

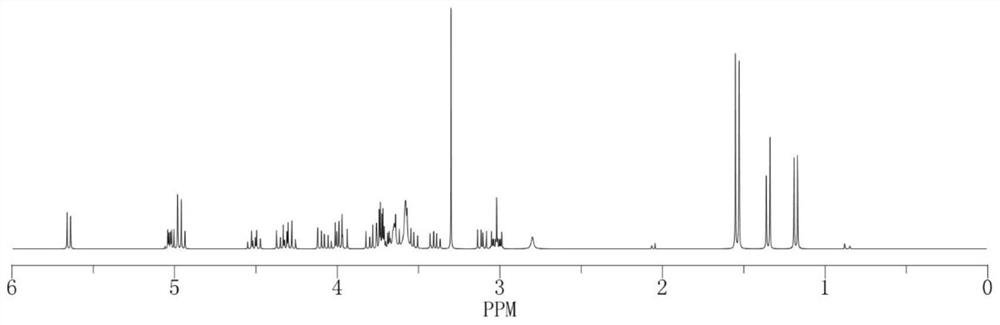

[0082] 1) Preparation of hydroxypropyl starch / lactic acid graft copolymer:

[0083] 1.1) Add 10g of hydroxypropyl cornstarch to 75g of 0.25mol / L sodium carbonate solution, heat up to 68°C at 4°C / min for gelatinization for 45min, then add 40g of lactic acid, reduce the system pressure to 0.1MPa, then raise the temperature to 80°C, and react 1h;

[0084]1.2) Step 1.1) Add acetone after the system is lowered to room temperature, settle, filter with suction and dry at 50°C to obtain ...

Embodiment 2

[0096] Example 2: Another Plant-Based Softgel Gum:

[0097] This embodiment provides another plant-based soft capsule rubber. The components, formulations, and preparation methods of the soft capsule rubber are basically the same as those in Example 1. The only difference is that in the components of this embodiment, fiber Instead of cellulose / polylactic acid graft copolymer, cellulose is used to prepare soft capsule rubber without polylactic acid graft modification.

Embodiment 3

[0098] Example 3: Another Plant-Based Softgel Gum:

[0099] This embodiment provides another plant-based soft capsule rubber, the composition, formula and preparation method of the soft capsule rubber are basically the same as those in Example 1, the only difference is that no fiber is added to the components of this embodiment Vegetable / polylactic acid graft copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com