Integrated cooker steam box capable of circularly pressurizing and injecting water and operation method thereof

An integrated stove and steam box technology, applied in the field of kitchen utensils, can solve the problems of increased steam box pressure, inability to fill water, damage to the heating plate, etc., to achieve the effects of increasing steam pressure, improving steaming quality, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

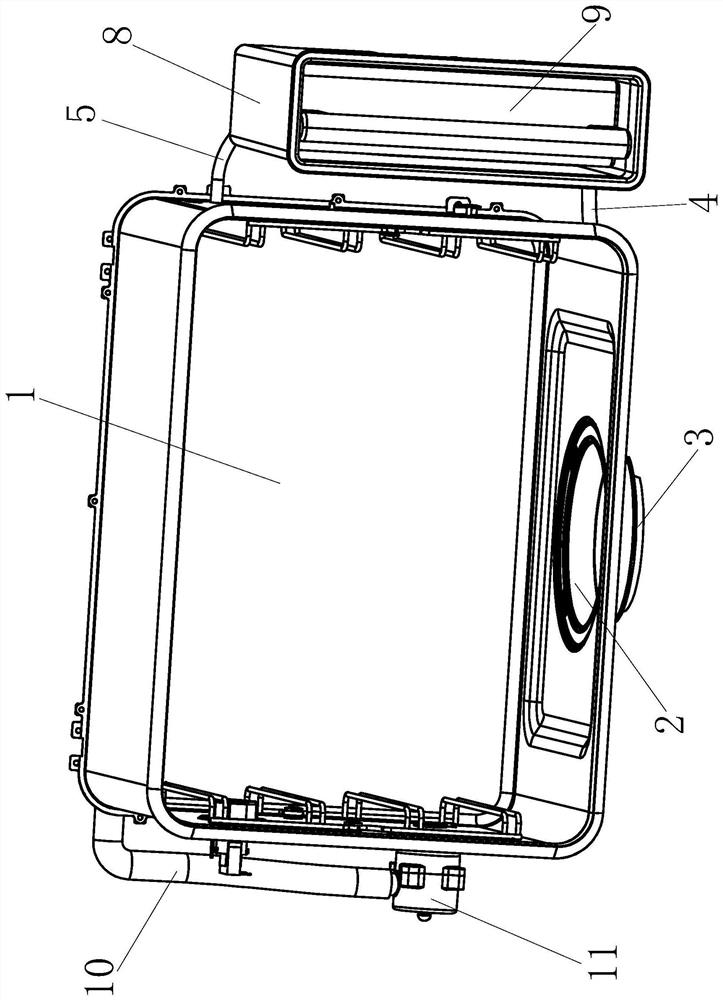

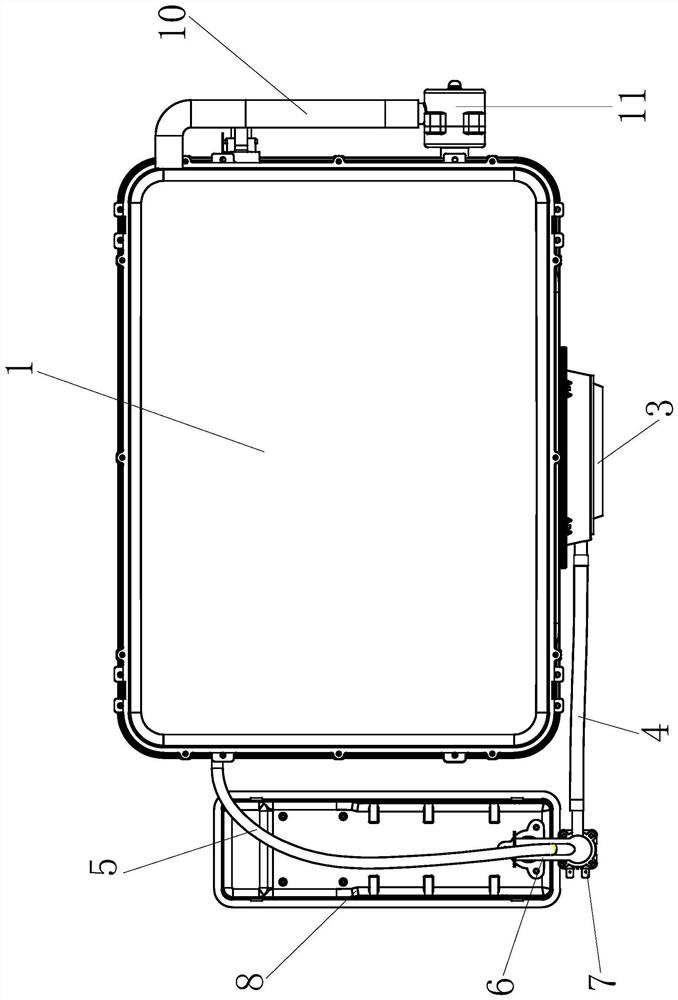

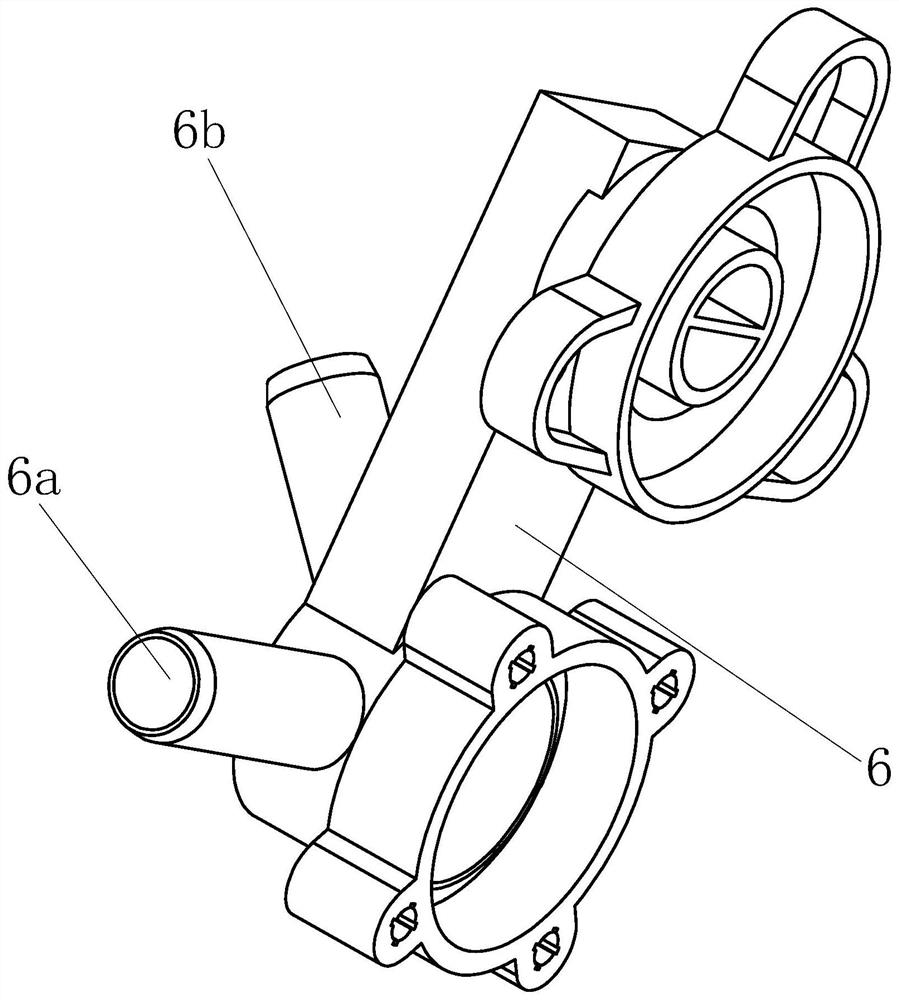

[0026] Such as Figure 1 to Figure 4 As shown, the integrated stove steamer for pressurized water injection in this cycle includes a steamer shell 1, which has an evaporation chamber inside, and a heating plate 2 is fixed at the bottom of the evaporation chamber, and the bottom of the heating plate 2 is fixed Heating wire 3, the bottom of one side of the steamer housing 1 is connected to the water inlet pipe 4, the outer end of the water inlet pipe 4 is connected to the bottom of a water box 9, and the same side top of the steamer housing 1 is opened with a small air outlet, and the air outlet is connected to the The water boxes 9 are connected through the air intake pipe 5, and the top of the other side of the steam box s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com