Component with a weld projection having a projection and lamp housing part comprising a component with a weld projection

A technology for bulges and lamp housings, applied in welding/welding/cutting articles, welding equipment, laser welding equipment, etc., can solve zinc coating evaporation, holes, sand holes and spatters in the connection area, failure to form welding connections, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

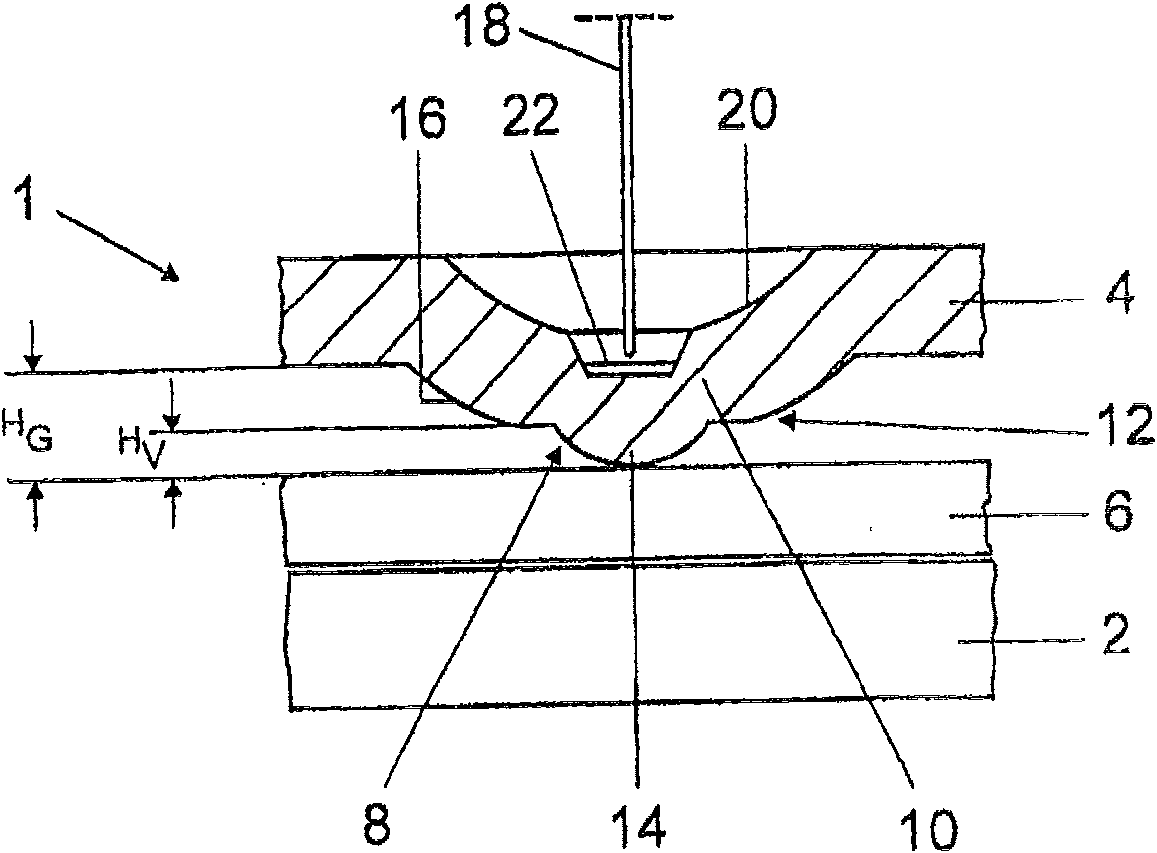

[0023] The invention will be illustrated below with the aid of welding projections for welding zinc-coated shielding housing parts. As already mentioned, the welding projections according to the invention are not limited to such housing parts only.

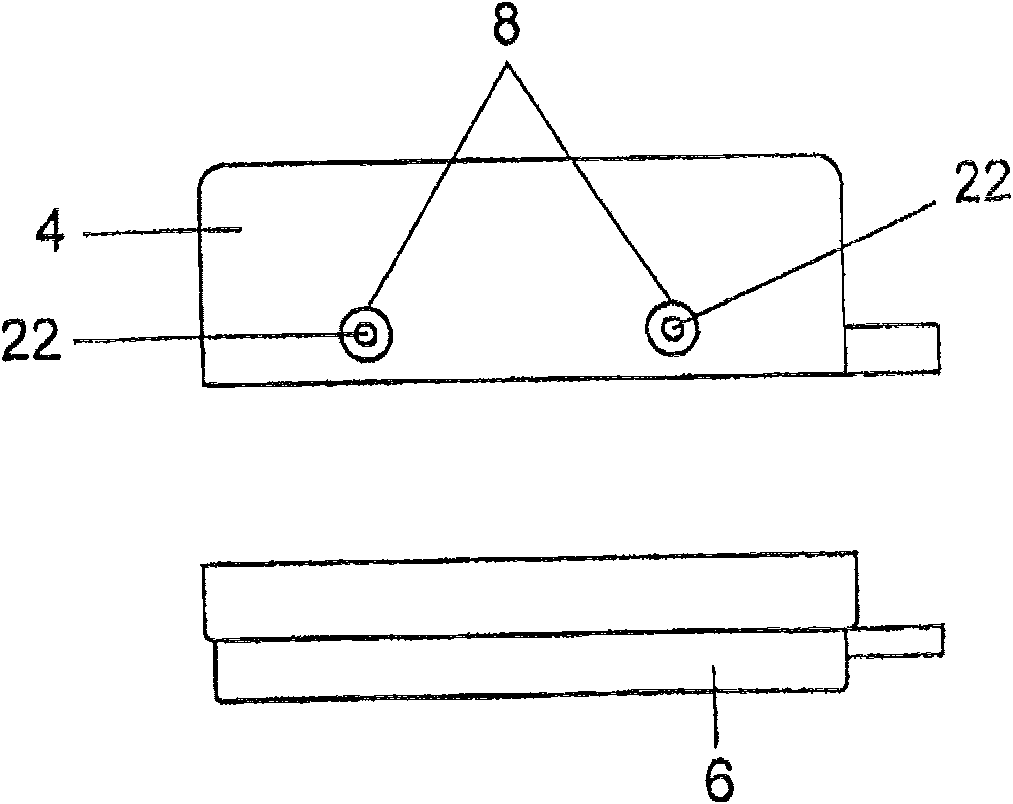

[0024] figure 2 A schematic illustration of a two-part, substantially cuboid shielding housing which surrounds the plastic lampholder 2 is shown. The upper part 4 of the shielding housing is provided on its top face with an opening (not shown) for the discharge chamber of the high-pressure discharge lamp. The lower part 6 overlaps the upper part 4 , so that in the area of the overlap the outer wall of the lower part 6 bears against the inner wall of the upper part 4 in the region of the welding bead 8 . Details of high-pressure discharge lamps are described, for example, in WO 00 / 59269. The shielding housing 1 has two housing parts 4, 6 made of galvanized sheet steel, which in their figure 1 A plurality of welding bumps 8 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com