High-electromagnetic-compatibility circuit board and manufacturing method thereof

A manufacturing method and technology of compatible wires, applied in the use/removal method of circuit mask, printed circuit manufacturing, circuit cover, etc., to achieve the effect of high pollution, low pass rate and quality, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

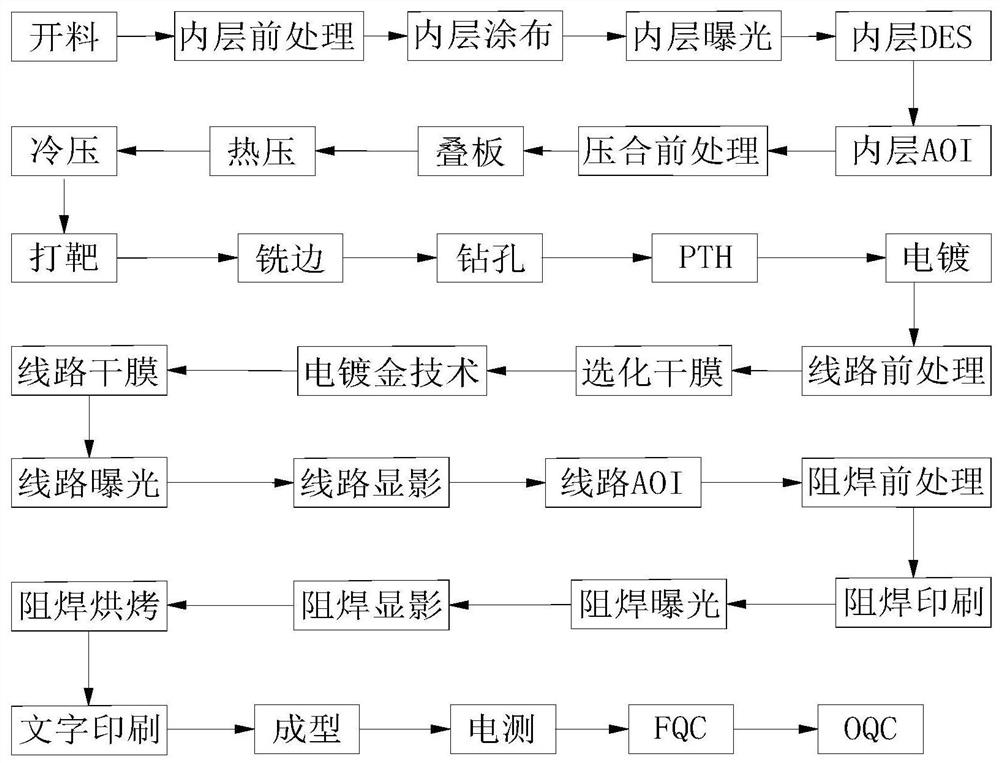

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further clarified below in conjunction with the accompanying drawings and specific embodiments.

[0013] The existing traditional circuit board production process is: material cutting—inner layer pretreatment—inner layer coating—inner layer exposure—inner layer DES—inner layer AOI—pre-pressing treatment—lamination—hot pressing—cold pressing— Targeting—edge milling—drilling—PTH—electroplating—line pretreatment—line dry film—line exposure—line DES—line AOI—solder mask pretreatment—solder mask printing—solder mask exposure—solder mask development—solder mask baking —Text printing—printing blue glue—gold plating—molding—electrical testing—FQC—OQC.

[0014] Although the above-mentioned traditional circuit board manufacturing method can realize the gold-plating process, the residue of the gold-plated wire and the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com