Microwave pre-oxidation technology for electric-control-type polyacrylonitrile protofilament

A technology of polyacrylonitrile and pre-oxidation, applied in the field of carbon fiber, can solve the problems of reducing the production cost of carbon fiber, large cost consumption of carbon fiber, etc., and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

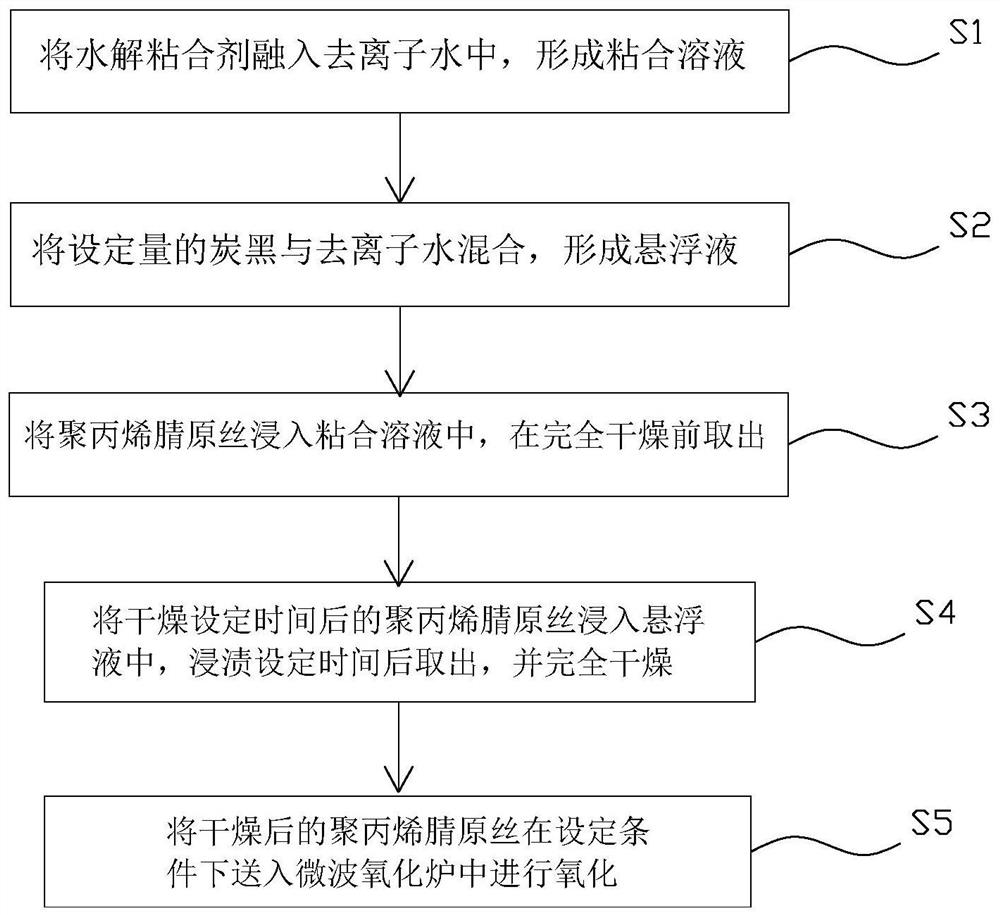

[0032] Such as figure 1 As shown, an electronically controlled polyacrylonitrile precursor microwave pre-oxidation process includes:

[0033] S1: Prepare a binding solution, and dissolve the hydrolyzed binder into deionized water to form a binding solution;

[0034] S2: Prepare a carbon black coating liquid, mix a set amount of carbon black with deionized water, the mass ratio of carbon black to deionized water is 10~15:100, and form a suspension;

[0035] S3: immerse the polyacrylonitrile precursor with a clean surface in the binding solution prepared in step S1, and take it out before it is completely dry;

[0036] S4: Immerse the polyacrylonitrile precursor after drying for a set time into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com