Dust Cooling Ball Forming Line

A production line, ash cooling technology, applied in the field of dust removal ash cooling ball forming production line, can solve the problems of easy breakage and splitting, poor bonding performance of dust removal ash cooling balls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

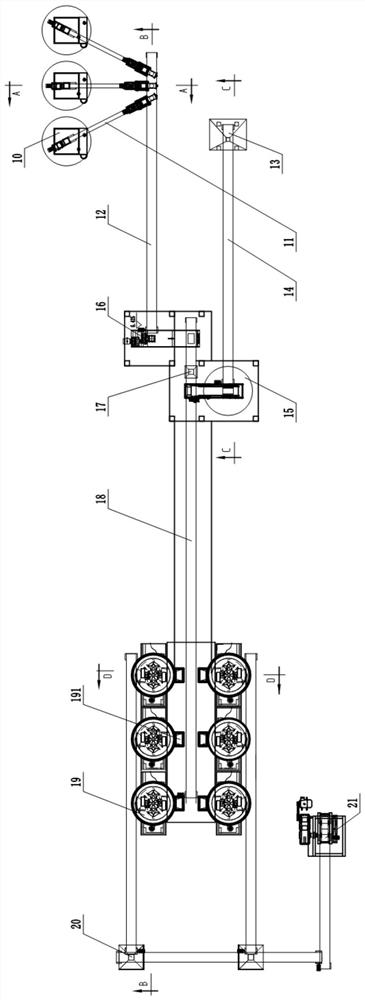

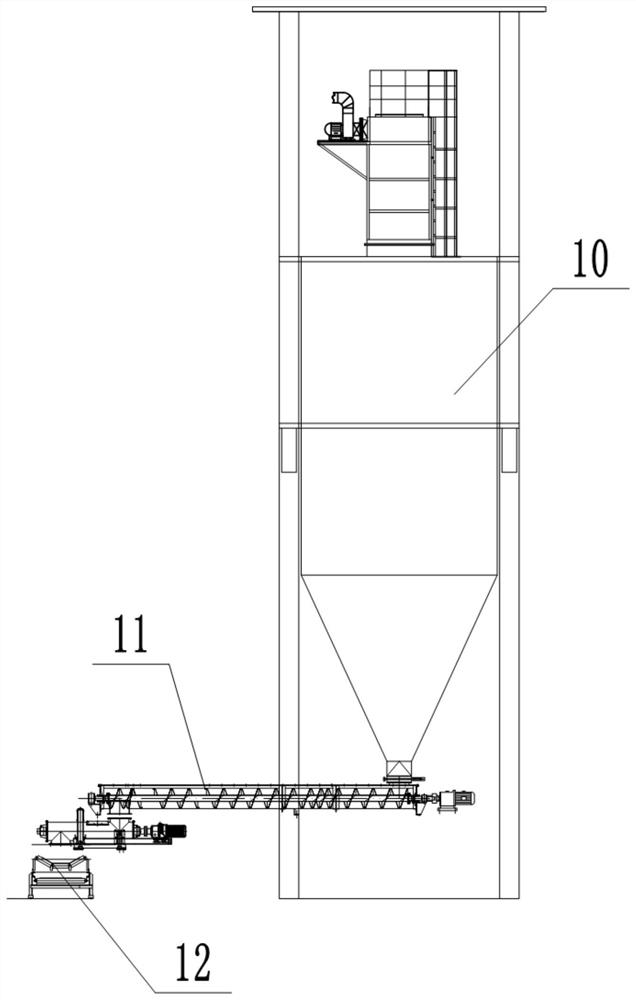

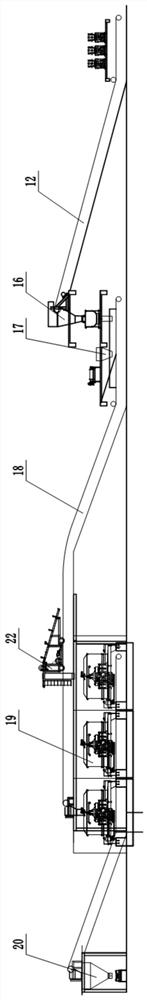

[0031] This embodiment is basically as figure 1 , image 3 Shown: Dedusting ash cooling ball forming production line, including wetting device, binder feeding device, iron-containing dust feeding system, dedusting ash feeding system, reaction kettle 19 and ball pressing machine 21 for pressing materials into balls. The dust removal ash feeding system is used to transport the dust removal ash to the wetting device, between the wetting device and the reactor 19, between the binder feeding device and the reactor 19, between the iron-containing dust feeding system and the reactor 19 A conveying device is provided. In this embodiment, the conveying device between the wetting device and the reactor 19, between the binder feeding device and the reactor 19, and between the iron-containing dust feeding system and the reactor 19 is the same The conveying device, the conveying device is the main belt conveyor 18, and the main belt conveyor 18 is used to transport materials such as dedus...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that: Figure 11 As shown, in this embodiment, a vibrating screen is also provided to screen out unqualified dedusting ash chilled balls. The ball pressing machine 21 comprises a casing, which is provided with two ball-forming assemblies facing oppositely. Five tape conveyors), the vibrating screen is located at the bottom of the transport device away from the ball briquetting machine 21, and the vibrating screen is provided with a transport mechanism, and the transport mechanism returns the unqualified dust removal ash cooling ball to the briquetting machine 21. Setting up a vibrating screen can effectively screen out unqualified dedusting ash cooling balls (not pressed into a spherical shape) and improve the qualified rate of finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com