Detection device for bulletproof performance of bulletproof ceramic

A detection device and performance technology, which is applied in the field of bulletproof ceramic detection equipment, can solve the problems that ceramics of different specifications cannot be fixed, the trajectory of flying debris cannot be captured, and the high-definition camera is damaged, so as to facilitate replacement, prevent bullet offset, and angle wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

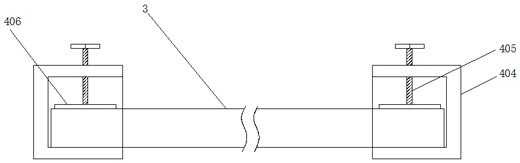

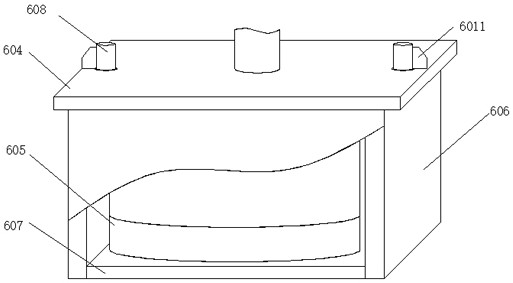

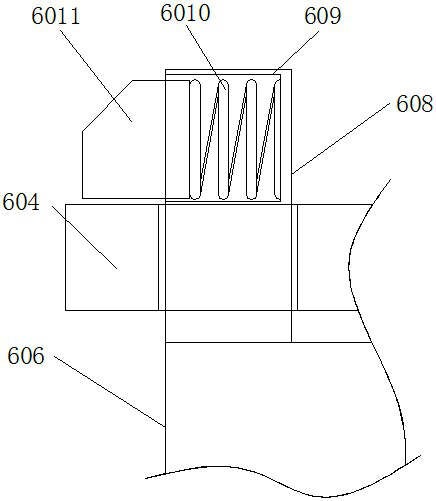

[0036] see Figure 1-6 , the present invention provides a technical solution: a detection device for the ballistic performance of bulletproof ceramics, including a placement table 1, two support plates 2 are welded and connected to the top side of the placement table 1, and the support plates 2 are internally connected with a bulletproof ceramic body 3. A disassembly assembly 4 is installed between the support plate 2 and the bulletproof ceramic body 3;

[0037] The inside of the disassembly assembly 4 includes a guide tube 401 that is fitted and connected to the inside of the support plate 2. The inside of the guide tube 401 is threaded with a T-shaped threaded rod 402, and one end of the T-shaped threaded rod 402 is fixedly connected with a connecting piece 403, and the connecting piece The other end of 403 is welded with a C-shaped plate 404, the internal thread of the C-shaped plate 404 is connected with a first hand-tightened bolt 405, and the other end of the first hand-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com