Inner combustion engine fuel supercritical ejection system and controlling method

An injection system, supercritical technology, applied in the direction of fuel injection control, fuel injection device, charging system, etc., can solve problems such as unreasonable energy use, achieve high realizability and reliability, and scientific and reasonable methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

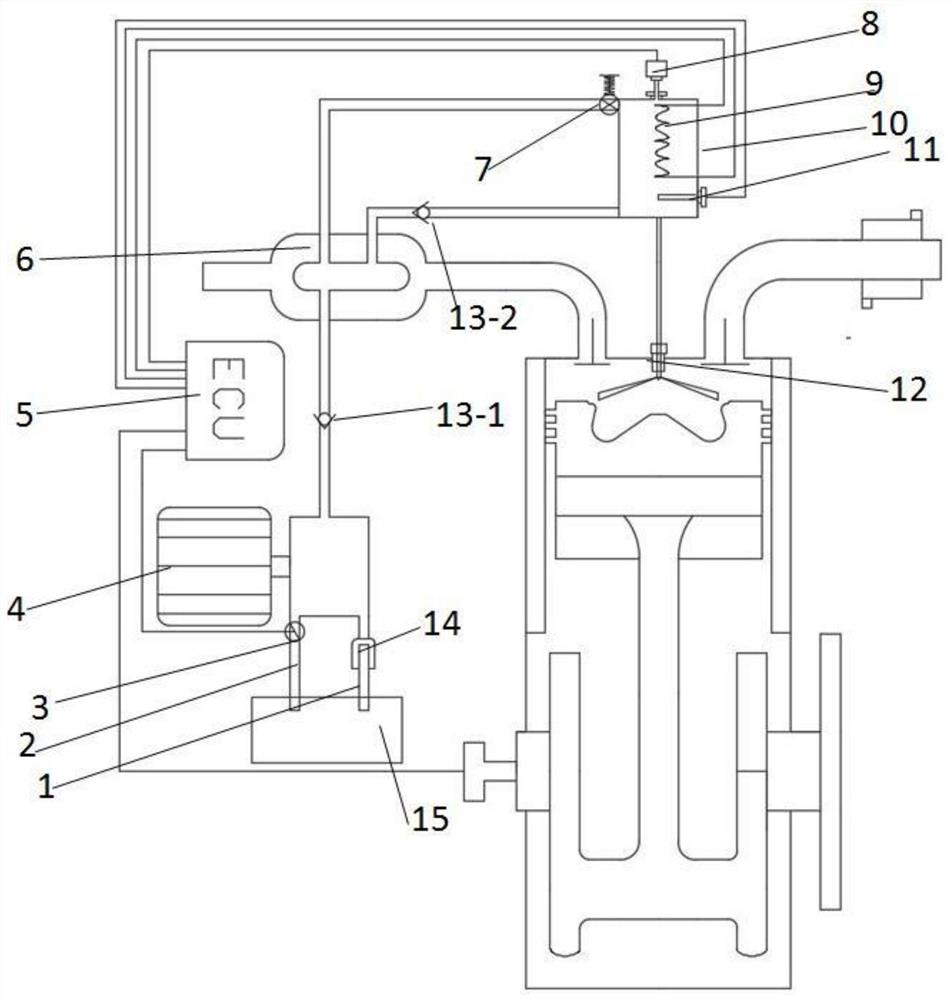

[0016] In order to better understand the content and features of the present invention, the technology of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] The present invention is to improve on existing engine structure, except figure 1 , the structure shown, the rest can adopt the existing structure.

[0018] A kind of internal combustion engine fuel supercritical injection system of the present invention as shown in the accompanying drawing, comprises the high-pressure oil pump 4 that is driven by the high-pressure oil pump gear in the engine timing gear box, and the oil inlet of described high-pressure oil pump is equipped with fuel filter The oil inlet pipe 1 of the cleaner 14 is connected to the oil tank 15, and the oil return port of the high-pressure oil pump is connected to the oil tank 15 through the oil return pipe 2 equipped with an electromagnetic flow valve 3, and the electromagnetic flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com