Shield receiving end reinforcing structure, reinforcing method and shield receiving method

A technology for strengthening structures and receiving methods, which is applied in the direction of earth cube drilling, mining equipment, tunnels, etc., can solve the problems of consuming large consumables, increasing the workload of construction workers, and increasing construction costs, so as to save consumables and avoid abnormal wear and tear , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

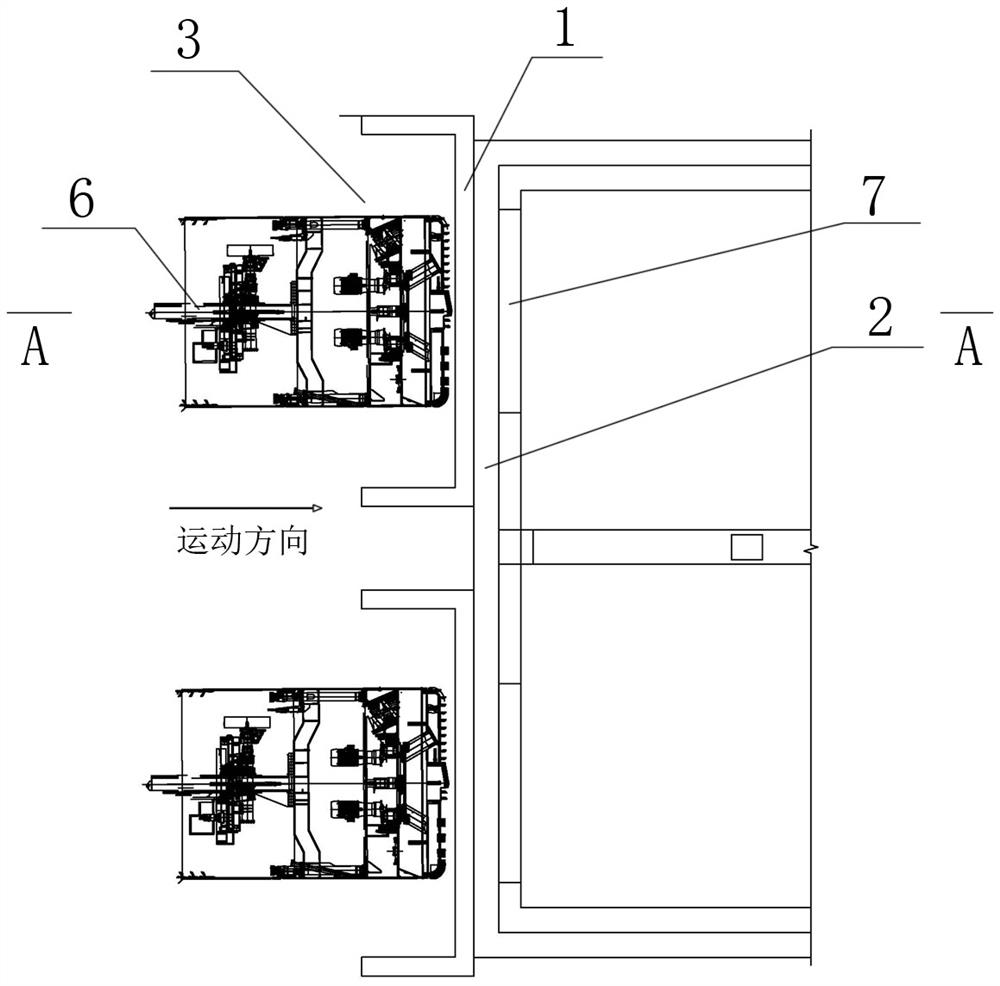

[0054] Such as figure 1 and figure 2 Shown is a shield receiving end, the reinforcement structure 1 of the shield receiving end is arranged in the soil body behind the enclosure structure 2 and one side of the reinforcement structure 1 is in contact with the enclosure structure 2 . The reinforcement structure 1 is a steel member driven vertically into the soil body. It should be noted that in the present invention, "front" refers to the same direction as the direction of movement of the shield machine, and "rear" refers to the direction opposite to the direction of movement of the shield machine.

[0055] In this embodiment, the reinforcing structure is cup-shaped, including a cup bottom 11 and two cup walls 12 arranged at the ends of the cup bottom 11 . The thickness of the cup bottom 11 and the cup wall 12 is 40-60cm. The opening of the reinforcement structure 1 of the receiving end of the shield faces the rear of the enclosure structure 2 , and the cup bottom 11 of the ...

Embodiment 2

[0062] Such as Figure 9 and 10 What is shown is the receiving end of the shield machine. The difference from the first embodiment is that the reinforcement structure 1 in this embodiment is in the shape of a straight line, and one side of the reinforcement structure 1 is in contact with the enclosure structure 2 . The reinforcement structure 1 has a width of 40-60 cm. The rest are all the same as in Example 1.

[0063] Such as Figure 11 As shown, the reinforcement structure 1 is a pipe curtain structure formed by closely arranged steel pipe piles.

[0064] Such as Figure 12 As shown, the reinforcement structure 1 is a Larsen steel sheet pile cofferdam structure.

[0065] Such as Figure 13 and 14 As shown, the reinforced structure 1 is an H-shaped steel curtain structure. in Figure 13 The medium H-beams are rotated 90° at intervals. Figure 14 The medium H-beams are arranged in parallel.

[0066] Such as Figure 15 and 16 , the reinforcement structure 1 is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com