An environmentally friendly silk quilt production process and device

A production process and technology for silk quilts, which are applied in silk reeling, silk fiber production, drying gas distribution, etc., can solve the problems of low precision of soda ash dosing, water cannot be reused, and no soda ash dosing device, etc., to improve production efficiency, The effect of convenient pick and place and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

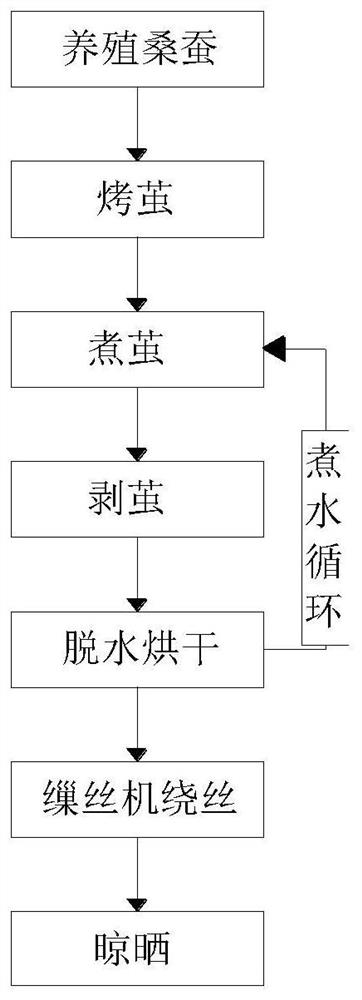

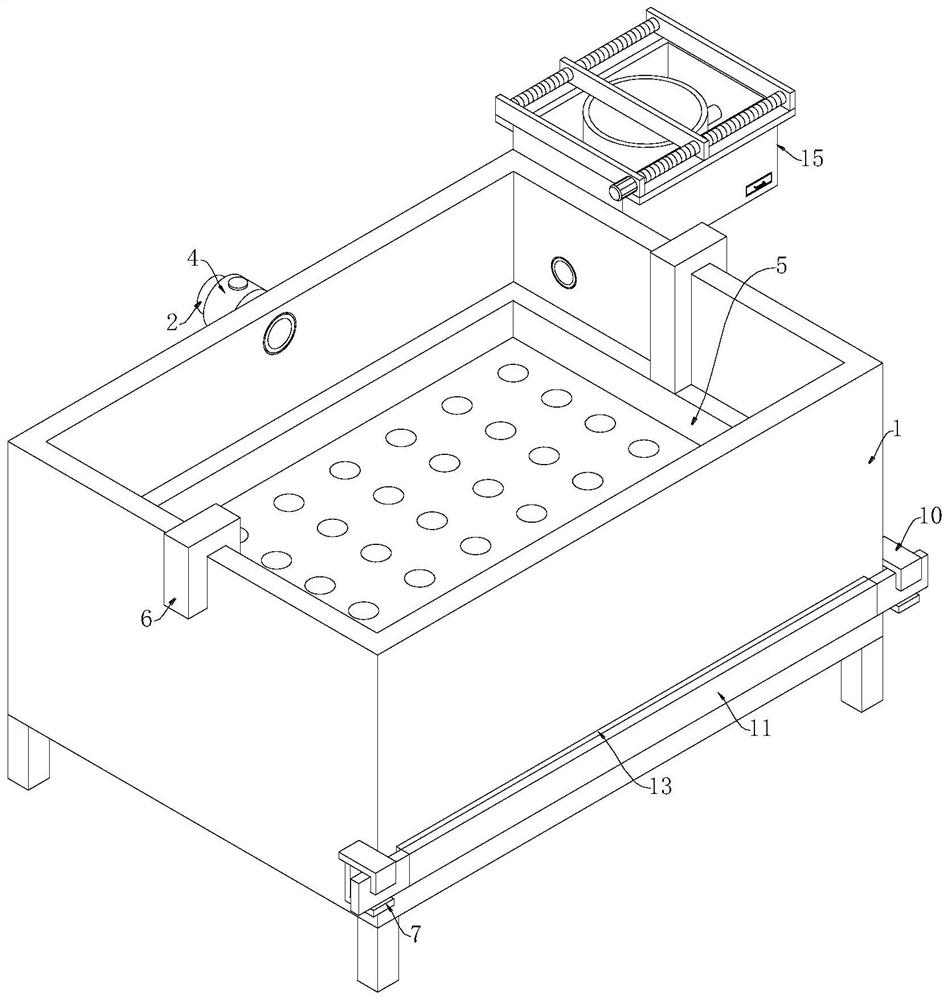

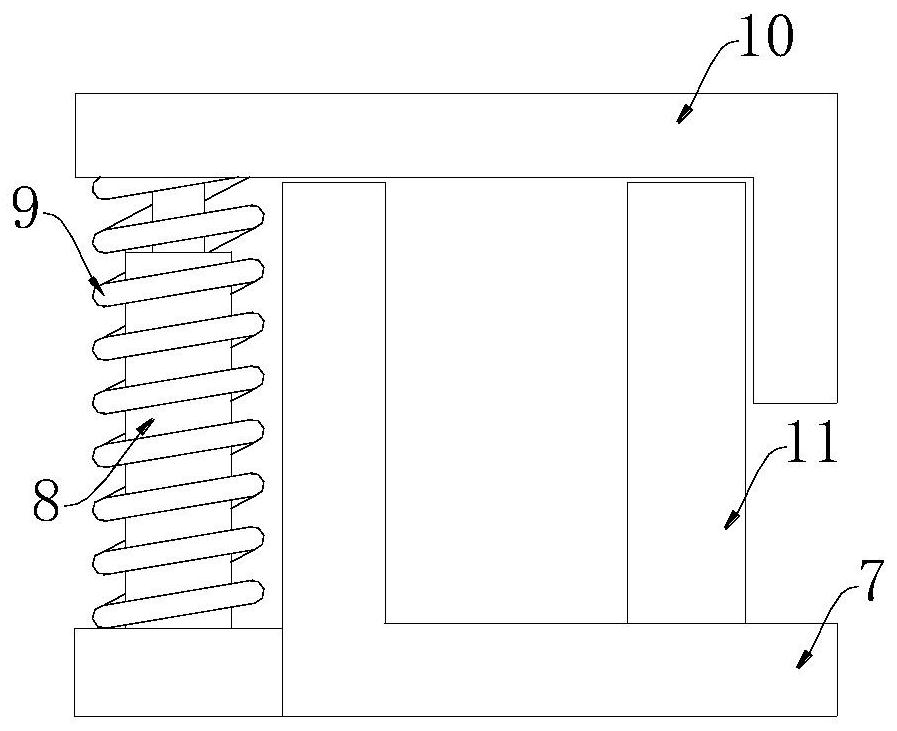

[0044] Example: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a kind of silk quilt manufacturing process of the present invention comprises the following steps:

[0045] S1. Breeding silkworms;

[0046] S2. Put the cocoons on the baking tray and push them into the oven to bake the cocoons. The baking temperature is set at 85°C and the baking time is set at 22min;

[0047] S3. Put the baked silkworm cocoons into the cocoon cooking mechanism, and add soda ash to the cocoon cooking mechanism through the feeding mechanism 15, control the water temperature to be 75°C, and control the boiling time to be 30 minutes; when the water temperature is 75°C, it must be controlled When the boiling time is 30 minutes, the conversion rate of soda ash is the highest value of 99.3, and when the boiling time is 30 minutes, it is only necessary to control the temperature at 75 °C, and there is no need to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com