Method for preparing S355MC steel coil based on multi-mode sheet billet continuous casting and rolling production line and product obtained from method for preparing S355MC steel coil based on multi-mode sheet billet continuous casting and rolling production line

A thin slab continuous casting and rolling production line technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of limited rolling mode, narrow thickness range, no advantages, etc., to achieve shortened total length, The production line is shortened and the effect of eliminating edge defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

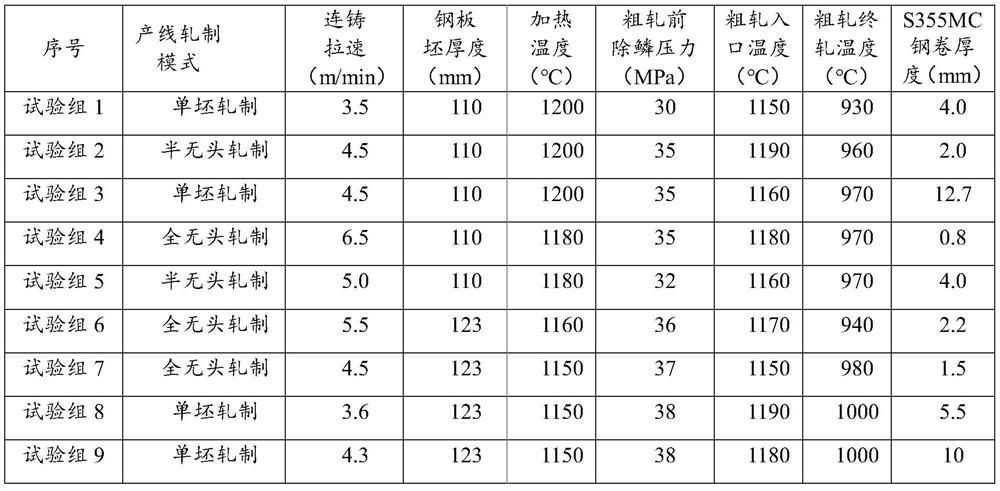

[0094] In this embodiment, 9 test groups are used. In the test groups 1-9, the S355MC steel coils are prepared by the preparation method based on the multi-mode thin slab continuous casting and rolling production line of the present invention;

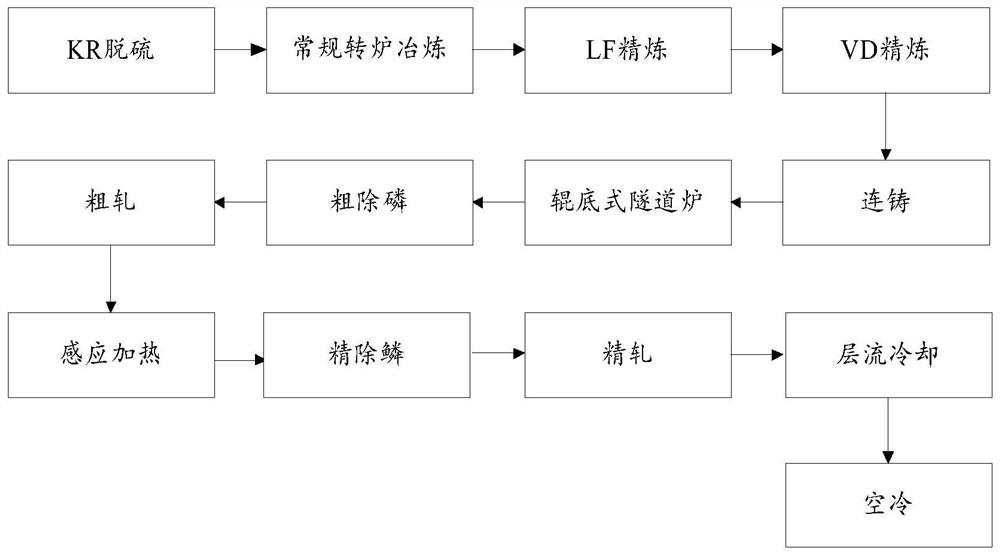

[0095] 1. The molten iron is subjected to KR desulfurization treatment, converter smelting, LF refining, VD refining, and continuous casting in sequence to obtain the steel slab. The chemical components contained in the steel slab are shown in Table 1 in terms of mass percentage;

[0096] Table 1: Chemical composition contained in the steel slab of the present invention

[0097] serial number C(%) Si(%) Mn(%) Al(%) P(%) S(%) Nb(%) N(%) Test group 1 0.03 0.032 0.75 0.035 0.009 0.0020 0.01 0.004 Test group 2 0.038 0.035 0.60 0.030 0.008 0.0040 0.020 0.003 Test group 3 0.040 0.030 0.78 0.042 0.01 0.0030 0.018 0.003 Test group 4 0.11 0.03 0.9 0.02 0.009 0.0020 0.08 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com