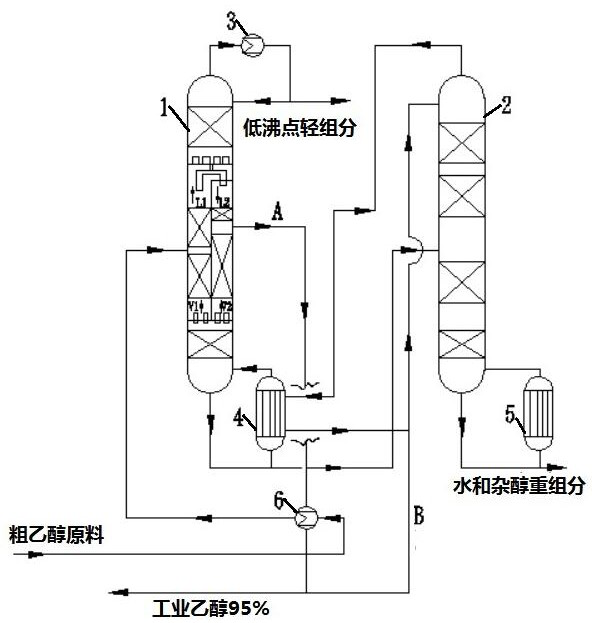

Novel process and device for separating and purifying industrial ethanol

A technology of industrial ethanol and new process is applied in the field of new processes and devices for separation and purification of industrial ethanol, which can solve the problems of low relative volatility and high energy consumption, and achieve the effect of saving steam and cooling water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Crude ethanol raw material for preparing ethanol from certain corn biomass (35% methanol, 60% ethanol, 4% water, 1% fusel alcohol), the feed rate is 20 tons / hour, and the operating conditions of the rectifying column with the next wall are: tower top The pressure is 150Kpa, the temperature at the top of the tower is 73°C, and the temperature at the bottom of the tower is 92°C. The output of industrial ethanol products is 6.31 tons / hour, and the product is 95.0wt%. Conditions: Tower top pressure 350Kpa, tower top temperature 113°C, tower kettle temperature 124°C, reflux ratio 3:1, production of industrial ethanol product 2 is 6.31 tons / hour, product purity 95.0%, separation element in the tower is Wire mesh structured packing BX500, the recovery rate of industrial ethanol is 99.9%, and the energy consumption of the separation process is 2.33 tons of saturated steam / ton of industrial ethanol product.

Embodiment 2

[0025] Example 2: Crude ethanol raw material (30% methanol, 62% ethanol, 5% water, 1% fusel alcohol) for preparing ethanol from certain potatoes and sugary raw material biomass, the feed rate is 10 tons / hour, and the rectifying column with the next wall Operating conditions: tower top pressure 130Kpa, tower top temperature 70°C, tower kettle temperature 95°C, output of industrial ethanol product: 2.71 tons / hour, product 95.0wt%, separation element in next-door tower is wire mesh structured packing BX500; Operating conditions of the ethanol rectification tower: tower top pressure 300Kpa, tower top temperature 110°C, tower bottom temperature 1124°C, reflux ratio 2:1, industrial ethanol product 2 output 3.81 tons / hour, product purity 95.0%, The separation element in the tower is wire mesh structured packing BX500, the recovery rate of industrial ethanol is 99.9%, and the energy consumption of the separation process is 2.34 tons of saturated steam / ton of industrial ethanol product....

Embodiment 3

[0026] Example 3: Crude ethanol raw material (40% methanol, 54% ethanol, 4% water, 2% fusel alcohol) for preparing ethanol from a synthesis gas through methyl acetate, the feed rate is 10 tons / hour, and the operating conditions of the rectifying column next to the wall : Tower top pressure 110Kpa, tower top temperature 65°C, tower kettle temperature 90°C, output of industrial ethanol products: 2.20 tons / hour, the product is 95.0wt%, the separation element in the next tower is wire mesh structured packing BX500; Distillation tower operating conditions: tower top pressure 250Kpa, tower top temperature 100°C, tower bottom temperature 115°C, reflux ratio 3:1, production of industrial ethanol product 2 is 3.19 tons / hour, product purity 95.0%, inside the tower The separation element is wire mesh structured packing, BX500, the recovery rate of industrial ethanol is 99.9%, and the energy consumption of the separation process is 2.32 tons of saturated steam / ton of industrial ethanol pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com