Two-stage paper shredding recovery device and using method

A recycling device and shredding technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high cost, large volume, inconvenient storage and recycling, etc., and achieve the effect of compressing volume and convenient recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

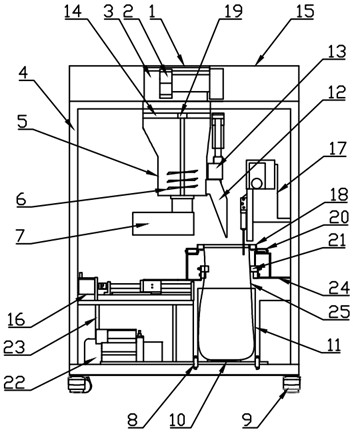

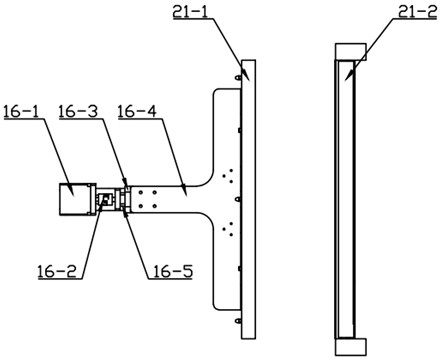

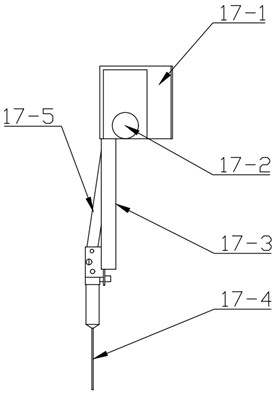

[0019] Such as figure 1 , figure 2 , Figure 5 As shown, a two-stage shredder recovery device includes a paper inlet 1, a first-stage motor 2, a first-stage shredder knife 3, and a frame 4. The first-stage motor 2 and the first-stage shredder knife 3 are arranged in parallel through gear connections On the upper end face of the frame 4, it also includes a secondary cylinder 5, a secondary cutter shaft 6, a secondary motor 7, a drawer I8, a waste paper bucket 11, a discharge port 12, a material retaining device 13, a bearing bracket 14, and Cover 15, module pushing mechanism 16, vacuum device 17, bag supporting mechanism 18, bearing 19, drawer II 20, heat sealing device 21, vacuum bag 25; Below the paper cutter 3; the frame upper cover 15 is arranged on the upper end of the frame 4 in a hinged manner, covering the first-stage motor 2 and the first-stage shredder knife 3; the paper inlet 1 passes through the frame upper cover 15, Align with the occlusal seam of the primary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com