Ceramic thermal barrier coating on surface of metal base body and application of ceramic thermal barrier coating in engine

A technology of thermal barrier coatings and metal substrates, applied in metal material coating technology, engine components, combustion engines, etc., can solve problems such as increasing hydrocarbon and carbon monoxide emissions, carbon deposits, automatic ignition, and early combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

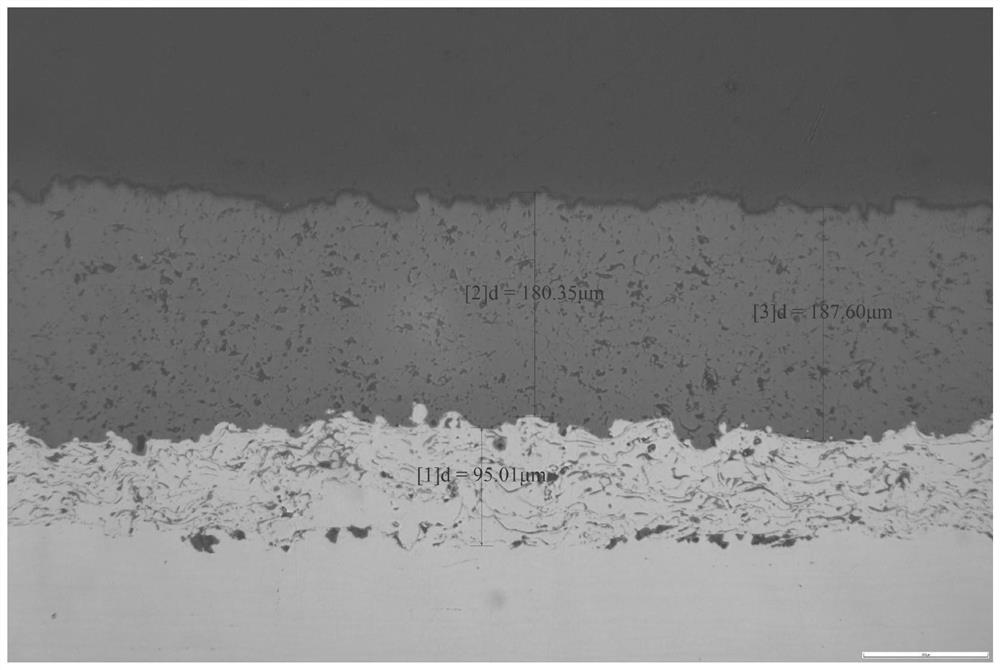

[0041] Such as figure 1 As shown, the MCrAlY bonding layer and the TBC top layer are sprayed on the turbine casing by atmospheric plasma spraying. The specific composition of the MCrAlY bonding layer is 37.0wt% Co content, 21.8wt% Cr content, 9.36wt% Al content, and 0.52% Y content wt%, Ni balance. The specific composition of the top layer of TBC is Y 2 o 3 Content 7wt%, Zr 2 o 3 margin. The thickness of the coating is uniform, the thickness of the MCrAlY bonding layer is 0.184mm, and the thickness of the TBC top layer is 0.095mm.

[0042] Due to the chemical combination between the coating and the substrate, the bonding strength is improved. In this embodiment, the bonding strength between the TBC top layer and the substrate at room temperature is 36MPa.

[0043] The MCrAlY bonding layer is located between the base metal and the thermal barrier ceramic surface layer, which has the dual functions of improving the physical compatibility of the coating and the base and ant...

Embodiment 2

[0046] Spray the bonding layer and the top layer on the turbine casing by cold spraying. The specific composition of the bonding layer is chromium magnesium phosphate binder content 43wt%-71wt%, spherical aluminum powder content 5wt%-15wt%, flake Aluminum powder content 7wt%-13wt%, Cr 2 o 3 The content is 16wt%-30wt%. The specific composition of the top layer is γ-Al 2 o 3 The content is 6wt%-14wt%, the chromium magnesium phosphate binder content is 67wt%-91wt%, and the BN content is 1wt%-8wt%. The thickness of the coating is uniform, the thickness of the bonding layer is 20-60um, and the thickness of the top layer is 10-50um.

[0047] In this embodiment, the bonding strength between the top layer and the substrate at room temperature is 35.5 MPa.

[0048] The bonding layer is between the turbine casing and the top layer, and has the effect of improving the physical compatibility, oxidation resistance and corrosion resistance of the coating and the substrate.

[0049] Th...

Embodiment 3

[0052] The bonding layer and the top layer are sprayed on the turbine casing by cold spraying. The specific composition of the bonding layer is 40wt%-65wt% of chromium magnesium phosphate binder, 7wt%-12wt% of spherical aluminum powder, flake Aluminum powder content 5wt%-16wt%, Cr 2 o 3 The content is 10wt%-33wt%. The specific composition of the top layer is γ-Al 2 o 3 Content 4wt%-24wt%, SiO 2 .nH 2 The O content is 60wt%-90wt%. The thickness of the coating is uniform, the thickness of the bonding layer is 10-70um, and the thickness of the top layer is 20-65um.

[0053] In this embodiment, the bonding strength between the TBC top layer and the substrate was tested at room temperature to be 35 MPa.

[0054] The bonding layer is located between the turbine casing and the top layer, and has the effect of improving the physical compatibility, oxidation resistance and corrosion resistance of the coating and the substrate. The thermal conductivity of the ceramic thermal barr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com