Boron nitride/graphene double-heat-conduction-base aerogel composite phase change material and preparation method thereof

A composite phase change material and boron nitride technology are applied in the field of boron nitride/graphene dual thermally conductive base aerogel composite phase change material and its preparation, which can solve the problem of decreasing latent heat of phase change, decreasing relative content of phase change material, Affect the application effect of materials and other issues, and achieve the effects of small changes in phase transition temperature and latent heat of phase transition, enhanced thermal stability performance, and good thermal cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

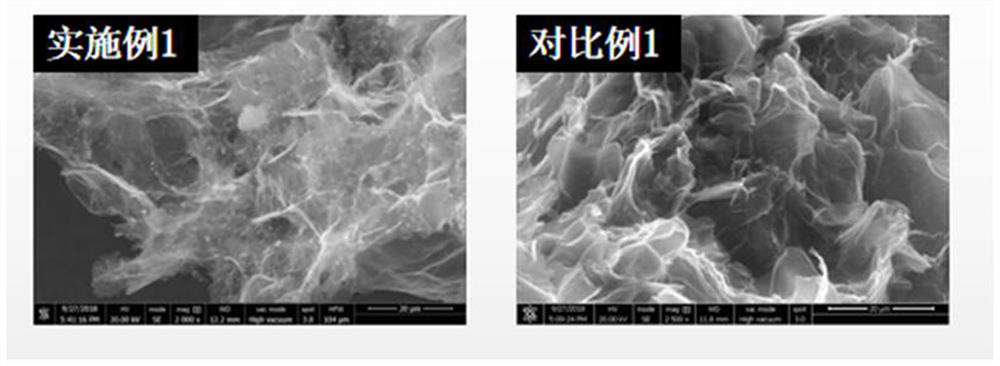

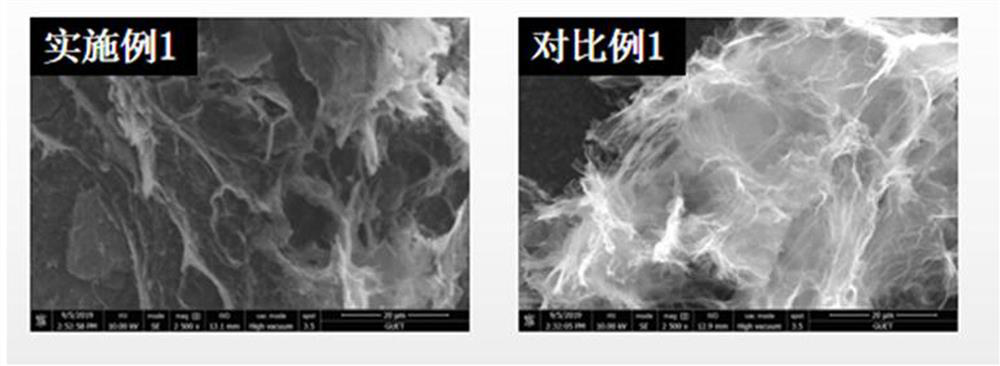

Embodiment 1

[0060] A preparation method of boron nitride / graphene dual thermally conductive base aerogel composite phase change material, comprising the following steps:

[0061] Step 1) Preparation of modified boron nitride, 5 g of boron nitride was placed in 200 mL of NaOH solution with a concentration of 5 wt%, and then stirred in a constant temperature water bath at 90 °C for 2 h to carry out the modification reaction. Filter and wash until the pH is neutral, then dry at 80°C for 24h and grind to obtain modified boron nitride;

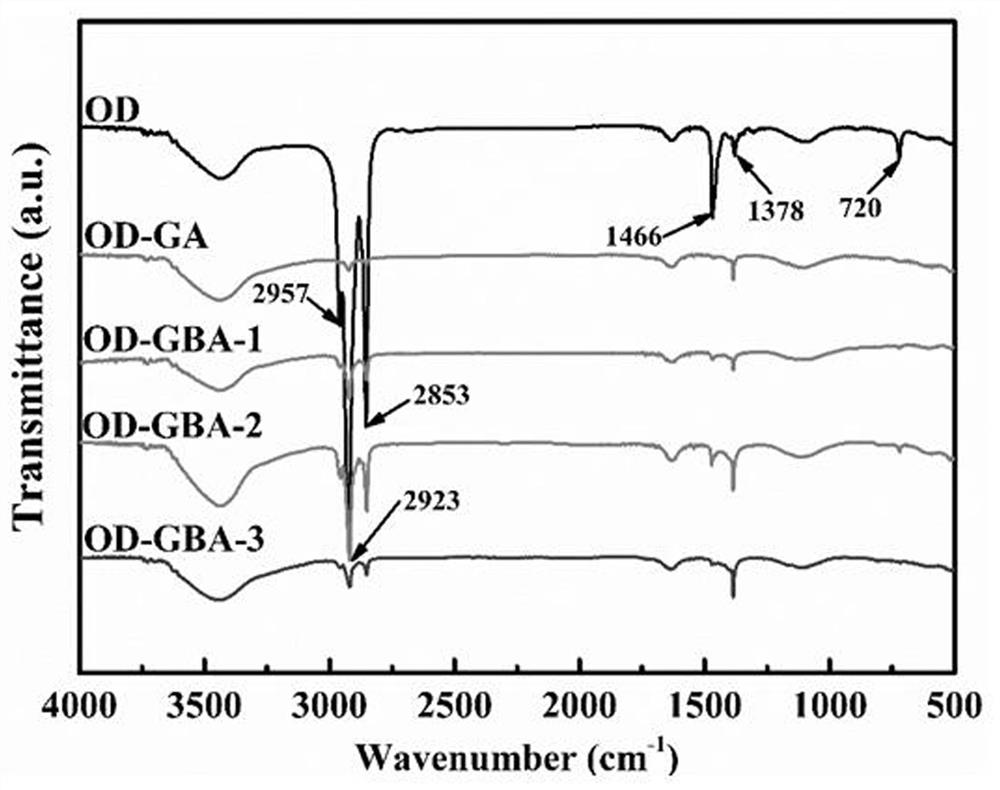

[0062] Step 2) Preparation of boron nitride / graphene dual thermally conductive base aerogel. First, the modified boron nitride obtained in step 1 is mixed with polyvinylpyrrolidone whose mass is 16% of the mass of boron nitride and deionized water for 30 minutes to obtain boron nitride solution, at the same time, the graphene oxide solution with a concentration of 10mg / mL was ultrasonicated for 30min to obtain a graphene oxide solution, and then the boron nitr...

Embodiment 2

[0079] A method for preparing a boron nitride / graphene dual thermally conductive base aerogel composite phase change material, the unspecified steps are the same as those in Example 1, the difference is: in the step 2, the modified boron nitride solute mass is added is 20% of the mass of the graphene oxide solute. The resulting sample was named OD / GBA-1.

[0080] After the mass calculation of the boron nitride / graphene dual thermally conductive base aerogel before and after impregnation, it can be seen that when the mass of the modified boron nitride solute is 20% of the solute mass of graphene oxide, the adsorption of 5.4 phase change material n-octadecane is relatively high. In Example 1, the adsorption amount decreased, indicating that with the decrease of the addition amount of boron nitride, the carrier provided by the boron nitride decreased, resulting in the decrease of the adsorbed phase change material.

[0081] To demonstrate the phase change properties of a boron n...

Embodiment 3

[0084] A method for preparing a boron nitride / graphene dual thermally conductive base aerogel composite phase change material, the unspecified steps are the same as those in Example 1, the difference is: in the step 2, the modified boron nitride solute mass is added Same mass as graphene oxide solute. The resulting sample was named OD / GBA-3.

[0085] After the mass calculation of the boron nitride / graphene dual thermally conductive base aerogel before and after impregnation, it can be seen that when the mass of the boron nitride solute is the same as the mass of the graphene oxide solute, 9g of n-octadecane, a phase change material, is adsorbed. The increase in the amount of adsorption effectively shows that the addition of boron nitride provides a carrier for the adsorption of the phase change material, which can increase the mass ratio of the phase change material.

[0086] To demonstrate the phase change properties of the as-prepared boron nitride / graphene dual thermally c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com