Orange disperse dye composition, orange disperse dye and preparation method and application of orange disperse dye

A technology for disperse dyes and compositions, applied in the field of dyes, can solve the problems of health and environmental hazards, a large number of equipment and labor, and high prices, and achieve the effects of easy raw materials, good upgradeability, and simple and easy preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The present invention also provides a preparation method of orange disperse dye according to the present invention, which comprises: in the presence of auxiliary materials, each dye component is carried out particle treatment with pulverizer; In the presence of a pulverizer, particle treatment was carried out, followed by mixing.

[0062] In some specific embodiments of the present invention, the various dye compound components of the orange disperse dye composition are mixed according to a specific proportion, and are mixed with a pulverizer such as a sand mill or a grinder in the presence of auxiliary agents and water. Carry out granulation treatment; the individual components in the orange disperse dye composition can also be granulated with a pulverizer such as a sand mill or a grinder in the presence of additives and water, and mixed in a specific proportion after granulation treatment.

[0063] In some specific embodiments of the present invention, the orange disp...

Embodiment 1

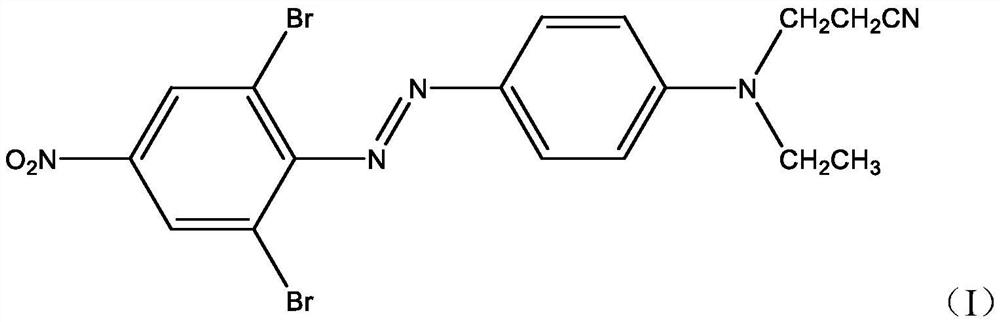

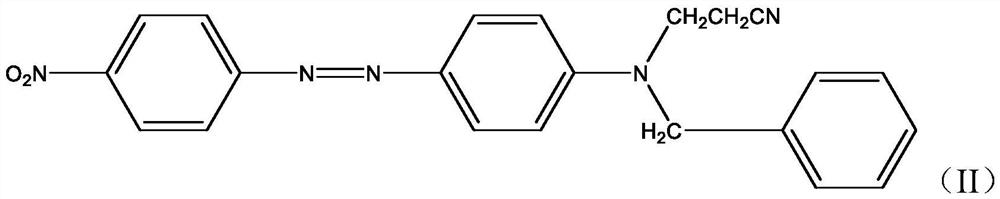

[0073] After dispersing and crushing 27 grams of compound of formula (I), 10 grams of compound of formula (II), 3.75 grams of compound of formula (III) and 1.5 grams of compound of formula (IV), add 22 grams of lignin 85A, 35.75 grams of dispersant MF Stir with 100 grams of water to disperse and dissolve, after continuous grinding or sand grinding to the end, repeat filtration, send to a spray drying tower through a pipeline for drying, and at the same time spray dust-proof oil evenly to obtain an orange disperse dye.

Embodiment 2~6

[0075] According to the structure and weight shown in Table 1, components A to D and auxiliary agents were mixed with water, and the method described in Example 1 was adopted to prepare orange disperse dye.

[0076] Table 1 Unit: Gram

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com