Short carbon fiber reinforced Csf/SiC ceramic matrix composite material and preparation method thereof

A short carbon fiber and composite material technology, applied in the direction of additive processing, can solve the problems of poor mechanical properties of SiC and short carbon fiber damage, and achieve the effects of good orientation, easy control and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

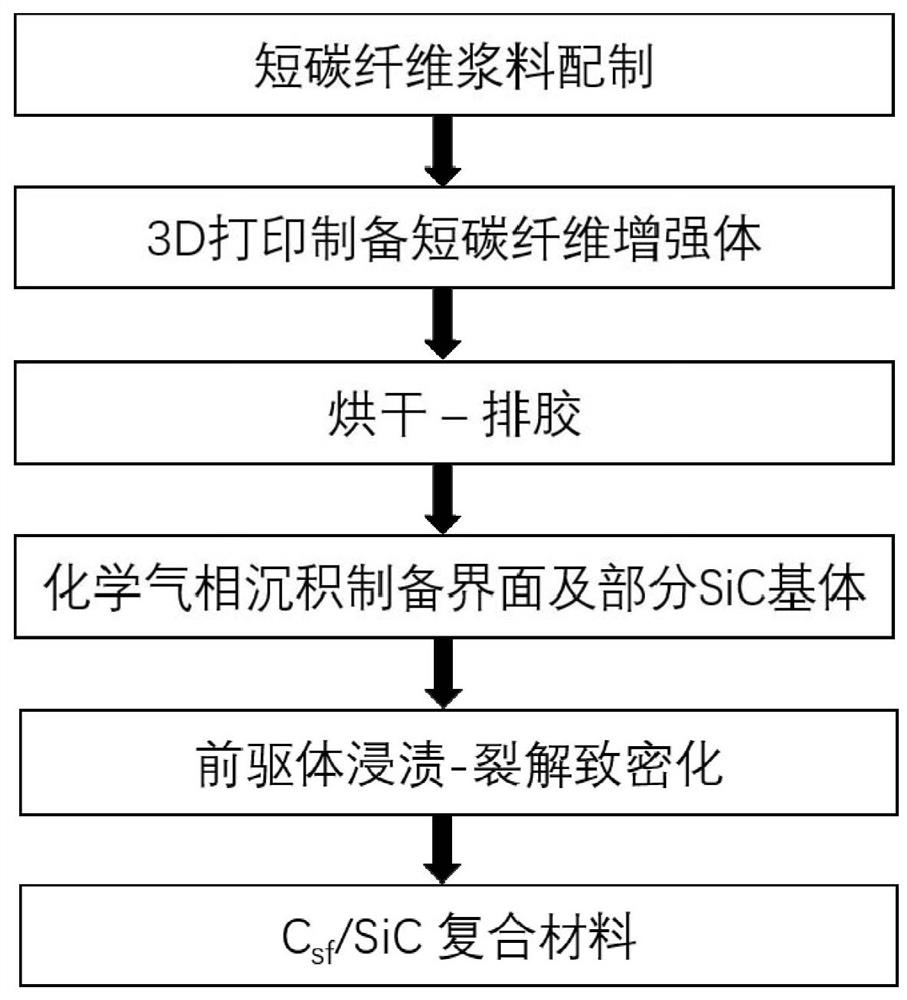

Method used

Image

Examples

Embodiment 1

[0047] (1) Mix deionized water and ethanol evenly according to the volume ratio of 1:2, add 1wt% of methylcellulose, 5wt% of PVP and 20wt% of short carbon fibers (with a diameter of 1 μm to 7 μm and a length of 0.05 mm to 1 mm) ) and mix well;

[0048] (2) The solvent is volatilized under the condition of magnetic heating and stirring until the solid content of the mixed system reaches ~65wt%, and the viscosity reaches ~40Pa·s (shear rate is 100 / s), and the mixture is loaded into the barrel used for 3D printing;

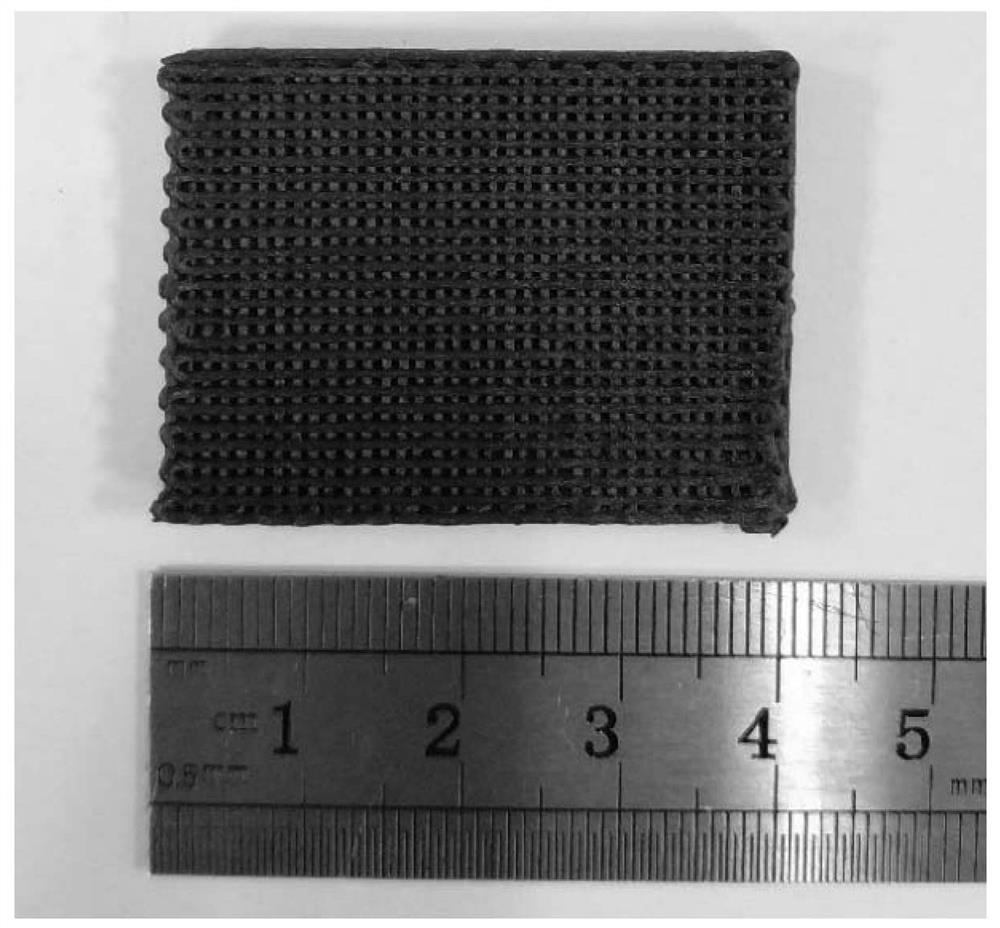

[0049] (3) Using a 0.84mm needle, based on the following printing parameters: layer thickness 0.6mm, line spacing 0.6mm, pressure: 0.45MPa; speed 2.8mm / s, print a reinforcement with short carbon fiber orientation, and then place it at 50°C 24h drying in the oven;

[0050] (4) Debinding: heat preservation at 1200°C for 0.5h under the protection of argon, and the heating rate is 5°C / min;

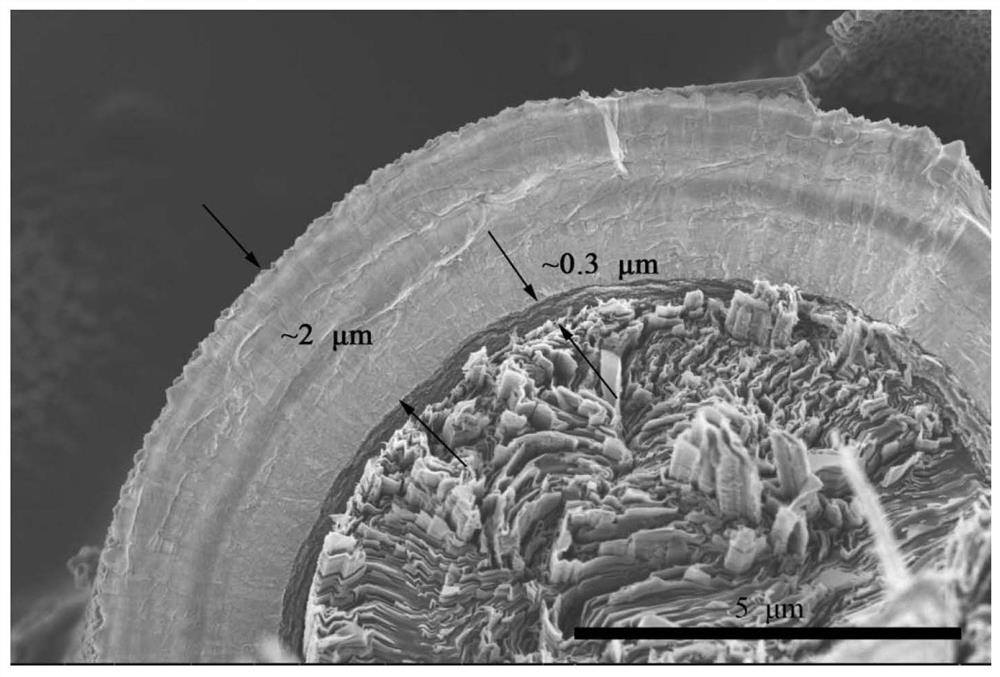

[0051] (5) Preparation of the interface layer and part of the SiC matrix: the ...

Embodiment 2

[0055] Similar to the steps in Example 1, the difference is that in step (3), a 0.64 mm needle is used, and the printing parameters are set as: layer thickness 0.5 mm, spacing 0.5 mm.

[0056] Gained C in this embodiment 2 sf The short carbon fiber content in the / SiC composite material is 30vol%, the bending strength of the material is 376±12MPa, the compressive strength is 415±13MPa, and the fracture toughness is 8.9±0.20MPa m 1 / 2 .

Embodiment 3

[0058] Similar to the steps in Example 1, the difference is: in step (1), the addition of methylcellulose is 1.5wt%, and the addition of binder is 7wt%;

[0059] Gained C in this embodiment 3 sf The short carbon fiber content in the / SiC composite material is ~21vol%, the material bending strength is 365±11MPa, the compressive strength is 420±12MPa, and the fracture toughness is 8.4±0.20MPa m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com