A precision machine for gear grinding

A technology of precision machinery and gears, applied in the field of gear grinding machinery, to achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

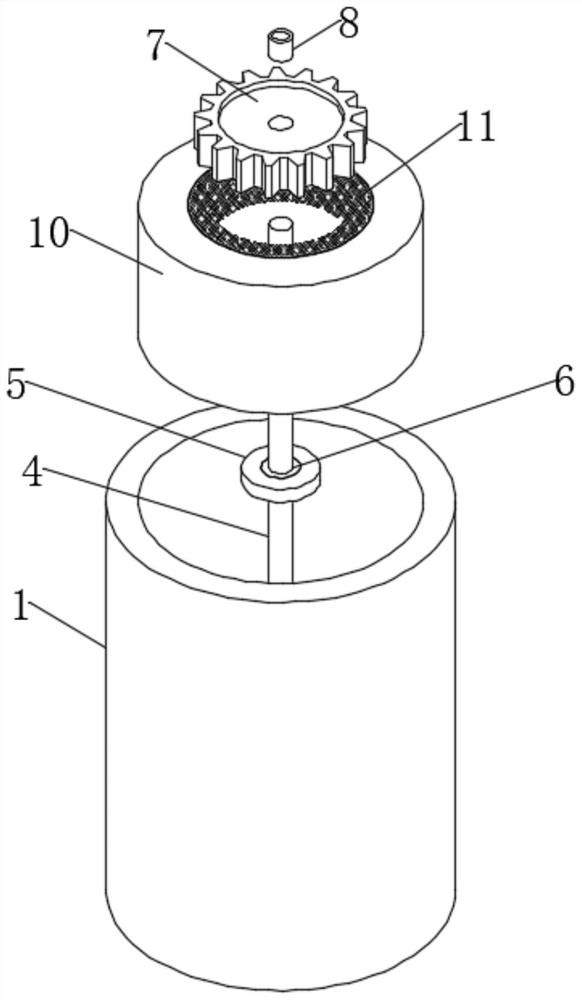

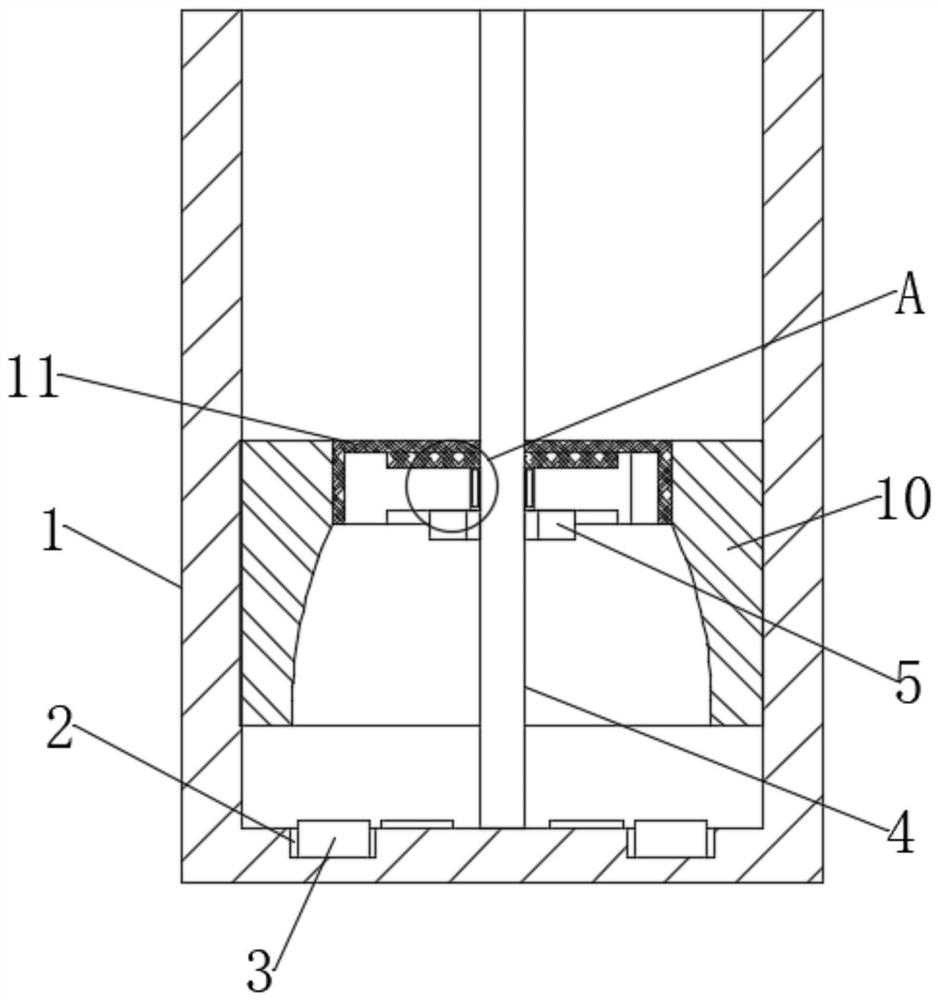

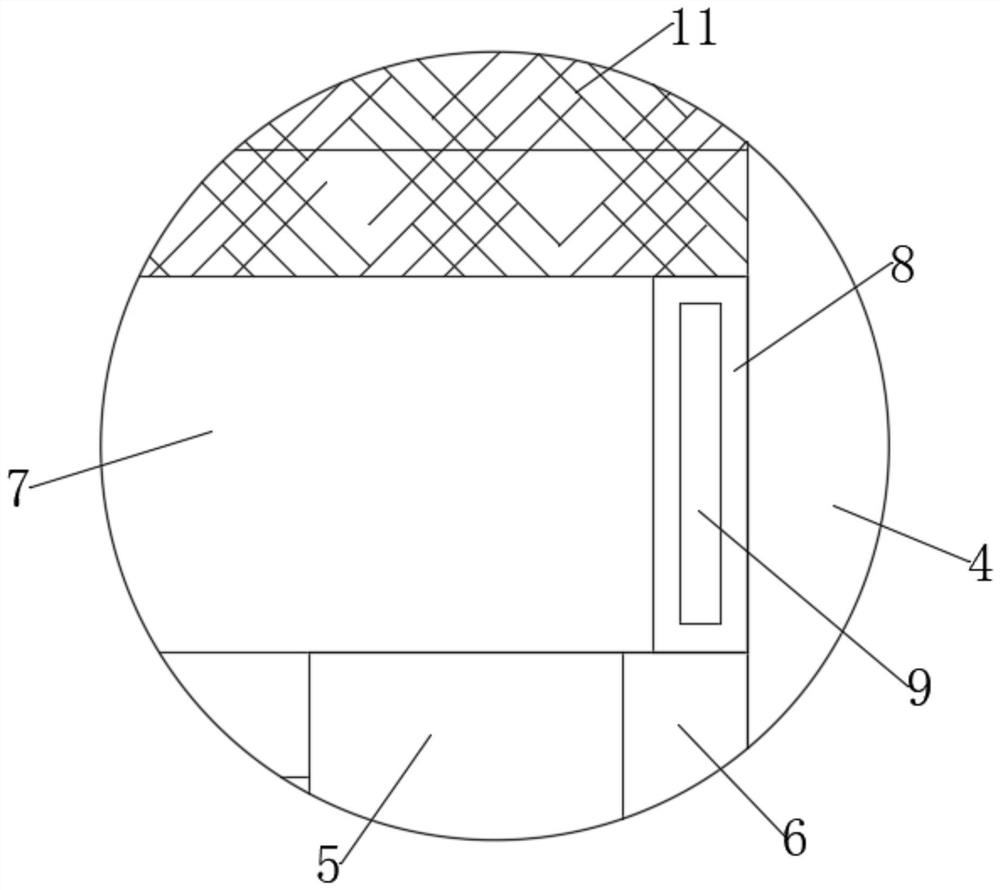

[0033] see Figure 1-3, a precision machine for gear grinding, comprising a housing 1, a plurality of installation grooves 2 are dug in the groove bottom of the outer cover 1, and the plurality of installation grooves 2 are evenly distributed on the groove bottom of the outer cover 1, and the installation grooves 2 are fixedly connected with The ultrasonic generating device 3 that matches itself, the groove bottom plate of the outer cover 1 is fixedly connected with the electric slider slide bar 4, and the electric slider slide bar 4 is slidably connected with the electric slider 5 that matches itself, and the outside of the electric slide block 5 A placement plate 6 is fixedly connected, and a gear main body 7 is placed on the placement plate 6. The gear main body 7 is sleeved on the outside of the electric slider slide rod 4. A wave condenser 10 is fixedly connected between the side walls of the outer cover 1. The wave condenser The inner wall of 10 is fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com