High-level splicing energy-consuming beam column node and manufacturing method

A beam-column node and high-position technology, which is applied to building components, earthquake resistance, and building types, can solve problems such as complex structure of energy-dissipating elements, difficulty in interspersing energy-dissipating ribs, low node redundancy and robustness, and achieve residual Small deformation, easy repair and function recovery, and avoid buckling instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

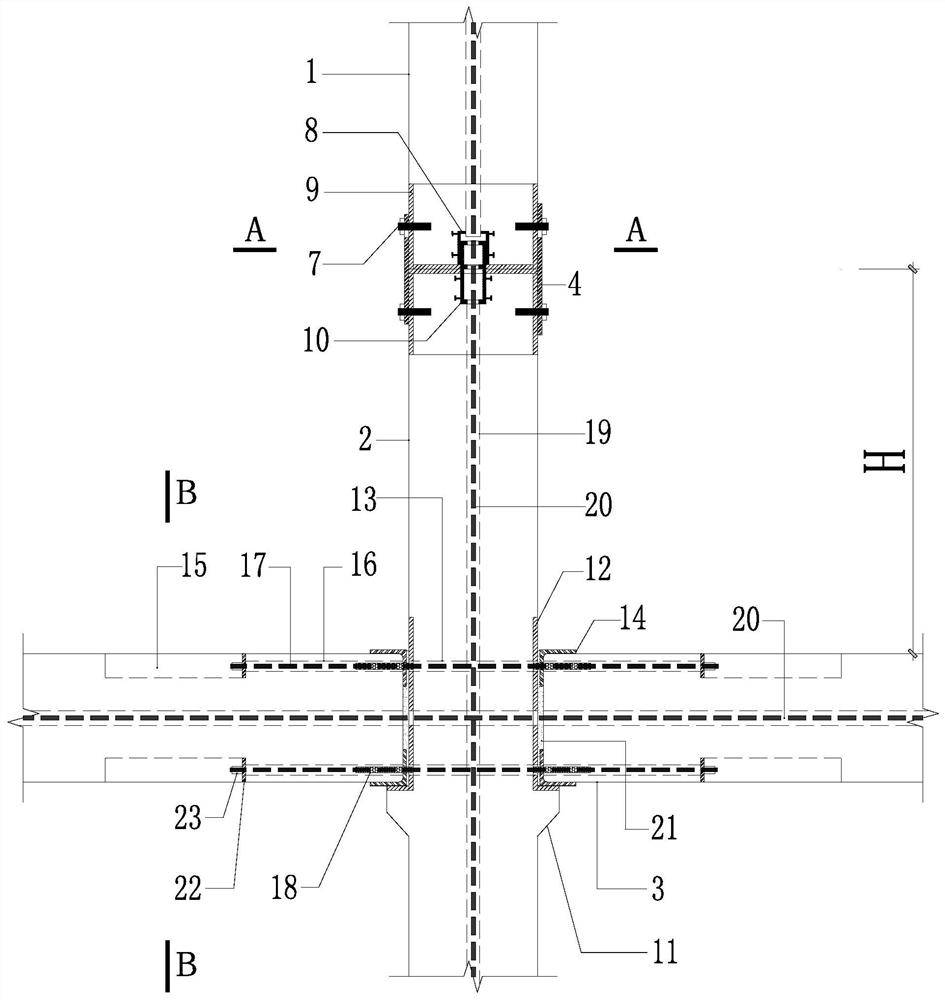

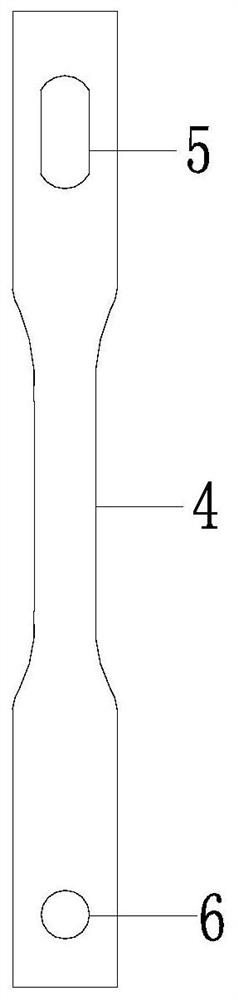

[0034] Such as Figure 1-5 As shown, this embodiment takes two frame columns as an example to describe the structure of the high-position splicing energy-consuming beam-column node: a high-position splicing energy-consuming beam-column node, which consists of: an upper prefabricated frame column 1; a lower prefabricated frame column 2; Prefabricated frame beam 3; Energy dissipation board 4.

[0035] Wherein, the upper prefabricated frame column 1 and the lower prefabricated frame column 2 (ie, the support columns mentioned above), combined with the production, transportation and hoisting capabilities of the prefabricated components, adopt a two-layer or three-layer prefabrication. The splicing surface of the upper prefabricated frame column 1 and the lower prefabricated frame column 2 is set at a position that is less stressed and convenient for construction, and the height (H) from the floor is generally 1 / 4 to 1 / 3 of the floor.

[0036] Wherein, the upper prefabricated frame col...

Embodiment 2

[0049] This embodiment provides a construction method for high-position splicing energy-consuming beam-column nodes, including the following steps:

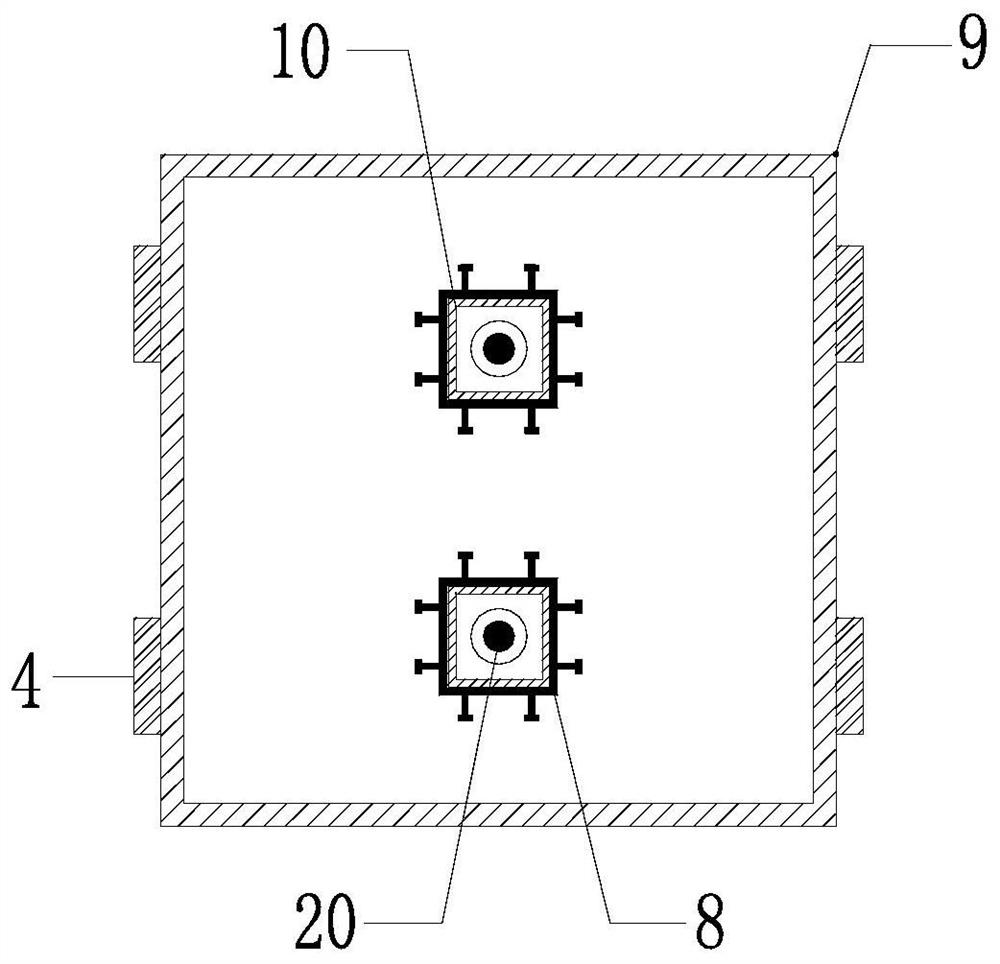

[0050] Step 1. When the upper prefabricated frame column 1 is prefabricated in the factory, a square steel tube 8 and a steel shoe 9 are pre-embedded at the bottom, and the embedded corrugated tube 19 forms a non-bonded prestressed rib tunnel, and the square outer tube 8 and the corrugated tube 19 are sealed. After the steel bars are tied up, the concrete is poured and cured;

[0051] Step 2. When the lower prefabricated frame column 2 is prefabricated in the factory, the shear key 10, the steel shoe 9 and the protective steel plate 12 are pre-embedded on the top, and the embedded corrugated pipe 19 forms a non-bonded prestressed tendon channel, the shear key 10 and the bellows 19 rooms are sealed, and bolt holes are provided at the position of connecting bolt 7. After the steel bars are tied up, the concrete is poured and cured. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com