Single-component waterproof high-hardness water-based floor paint and preparation method thereof

A high-hardness, floor paint technology, applied in the field of floor paint, can solve the problems of poor water resistance, low hardness, poor wear resistance, etc., and achieve the effect of reducing the possibility of efflorescence, improving weather resistance, and promoting emulsion cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

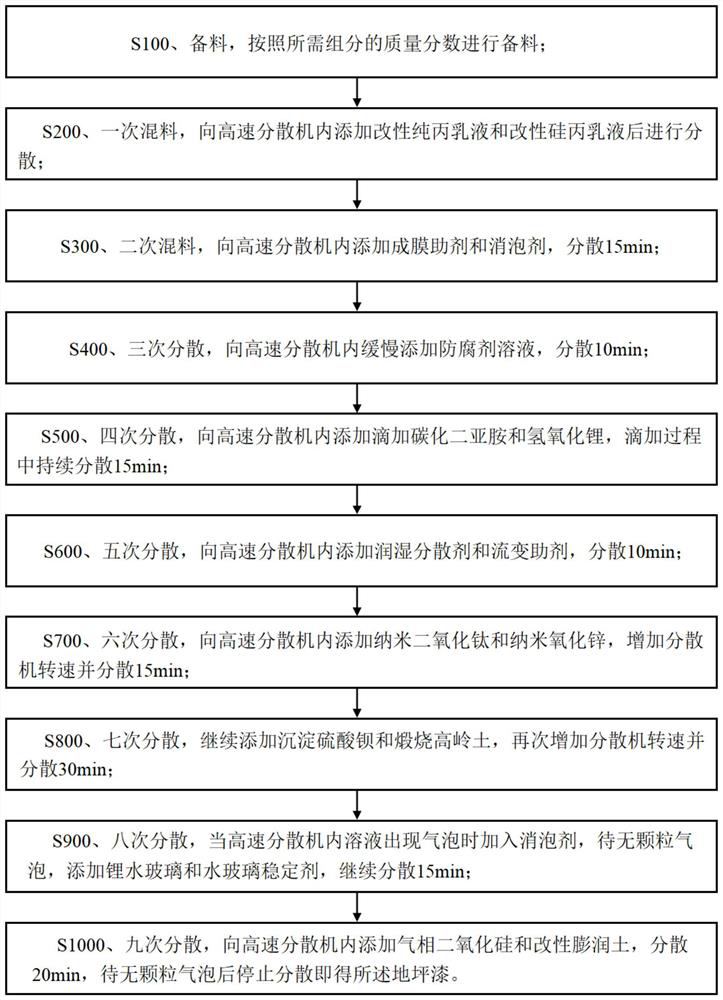

Image

Examples

Embodiment 1

[0034] Refer to the attached figure 1 , a one-component waterproof high-hardness water-based floor paint of the present embodiment includes the following components:

[0035] 10-25 parts of modified pure acrylic emulsion, 15-25 parts of modified silicone-acrylic emulsion, 0.7-1 part of film-forming aid, 20-30 parts of lithium water glass, 5-7 parts of calcined kaolin and 7-10 parts of precipitated barium sulfate share.

[0036] It also includes 0.1-0.3 part of lithium hydroxide, 1.5-2 part of polycarbodiimide, 0.1-0.2 part of wetting and dispersing agent and 0.1-0.2 part of rheology aid.

[0037] It also includes 0.2-0.4 parts of defoamer, 0.2-0.4 parts of preservatives, 3-5 parts of nano-zinc oxide and 10-15 parts of nano-titanium dioxide.

[0038] Also included are 0.1-0.3 parts of water glass stabilizer, 1-1.5 parts of fumed silica and 1-1.5 parts of modified bentonite.

[0039] A preparation method of one-component waterproof high-hardness water-based floor paint, speci...

Embodiment 2

[0055] A one-component waterproof high-hardness water-based floor paint and a preparation method thereof of the present embodiment specifically include the following steps:

[0056] S100, prepare materials, prepare materials according to the mass fraction of the required components;

[0057] S200, one-time mixing, adding modified pure acrylic emulsion and modified silicone-acrylic emulsion to the high-speed dispersing machine and then dispersing;

[0058] S300, secondary mixing, add film-forming aids and defoamer to the high-speed disperser, and disperse for 15 minutes;

[0059] S400, disperse three times, slowly add preservative solution to the high-speed disperser, and disperse for 10min;

[0060] S500, four times of dispersion, add dropwise carbodiimide and lithium hydroxide to the high-speed disperser, and continue to disperse for 15min during the dropwise addition;

[0061] S600, five times of dispersion, add wetting and dispersing agent and rheology aid to the high-spe...

Embodiment 3

[0071] A one-component waterproof high-hardness water-based floor paint and a preparation method thereof of the present embodiment specifically include the following steps:

[0072] S100, prepare materials, prepare materials according to the mass fraction of the required components;

[0073] S200, one-time mixing, adding modified pure acrylic emulsion and modified silicone-acrylic emulsion to the high-speed dispersing machine and then dispersing;

[0074] S300, secondary mixing, add film-forming aids and defoamer to the high-speed disperser, and disperse for 15 minutes;

[0075] S400, disperse three times, slowly add preservative solution to the high-speed disperser, and disperse for 10min;

[0076] S500, four times of dispersion, add dropwise carbodiimide and lithium hydroxide to the high-speed disperser, and continue to disperse for 15min during the dropwise addition;

[0077] S600, five times of dispersion, add wetting and dispersing agent and rheology aid to the high-spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com