Anti-cracking high-strength aerated building block

A high-strength technology of aerated blocks, applied in the field of building materials, can solve the problems of impermeability and compressive strength of autoclaved aerated concrete blocks, and the difficulty of applying autoclaved aerated concrete blocks to load-bearing walls. Achieve the effect of increasing aggregate packing density, compactness, compressive strength and cracking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

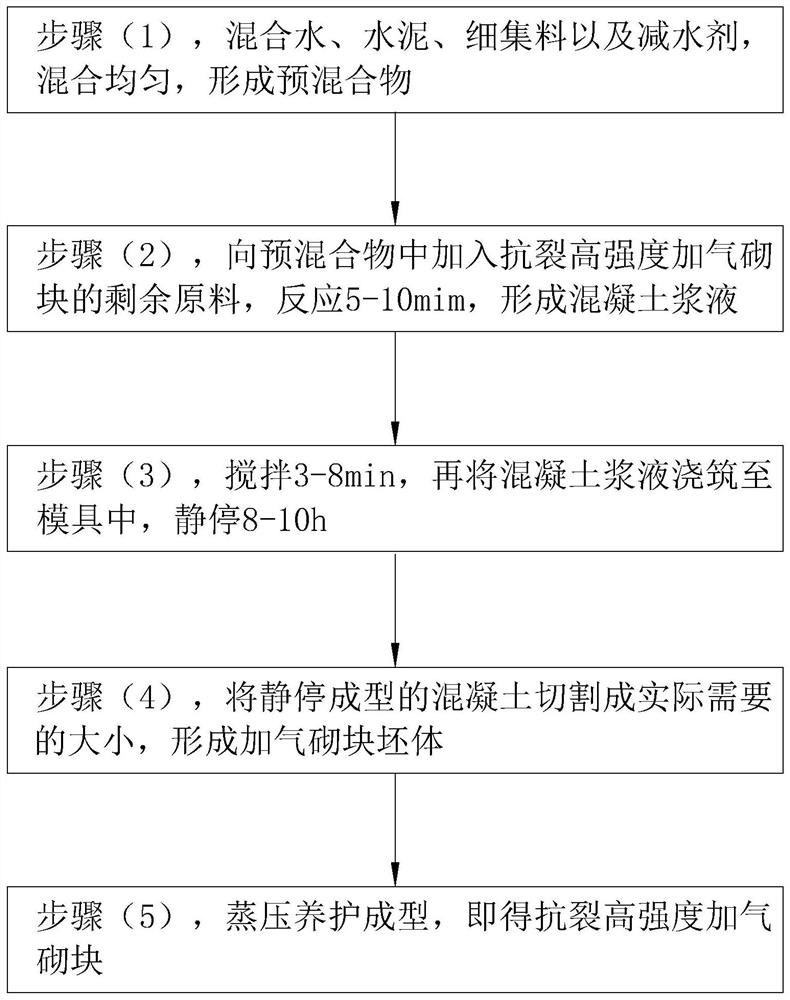

[0072] refer to figure 1 , is a method for preparing a crack-resistant high-strength aerated block disclosed by the present invention, comprising the following steps:

[0073] Step (1), adding water, cement, fine aggregate and water reducing agent into the mortar mixer, stirring and mixing evenly to form a pre-mixture.

[0074] Step (2), add foaming agent, polydimethylsiloxane, cobalt 2-ethylhexanoate and benzoin dimethyl ether to the pre-mixture while stirring, stir and mix evenly, let it stand for 5 minutes to form concrete slurry.

[0075] Step (3), stir for 3 minutes, then pour the concrete slurry into the mold, and send the mold poured with the concrete slurry to the static curing room to allow sufficient foaming and static curing, and control the static curing temperature to 60 ℃, control static stop curing time is 8h.

[0076] In step (4), the statically formed concrete in step (3) is demoulded first, and then the concrete is cut into actual required specifications t...

Embodiment 2

[0081] The difference of embodiment 1 is:

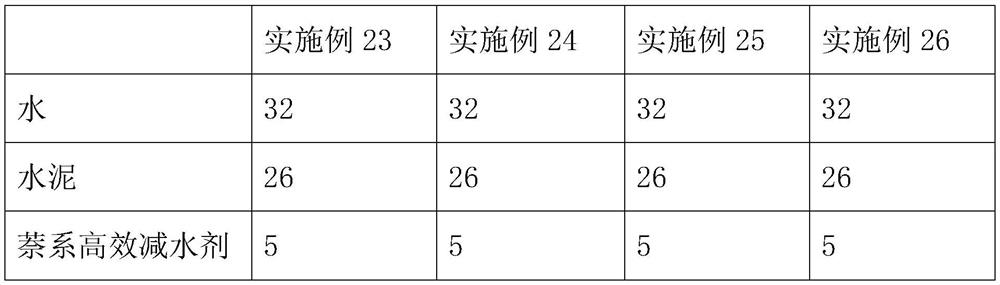

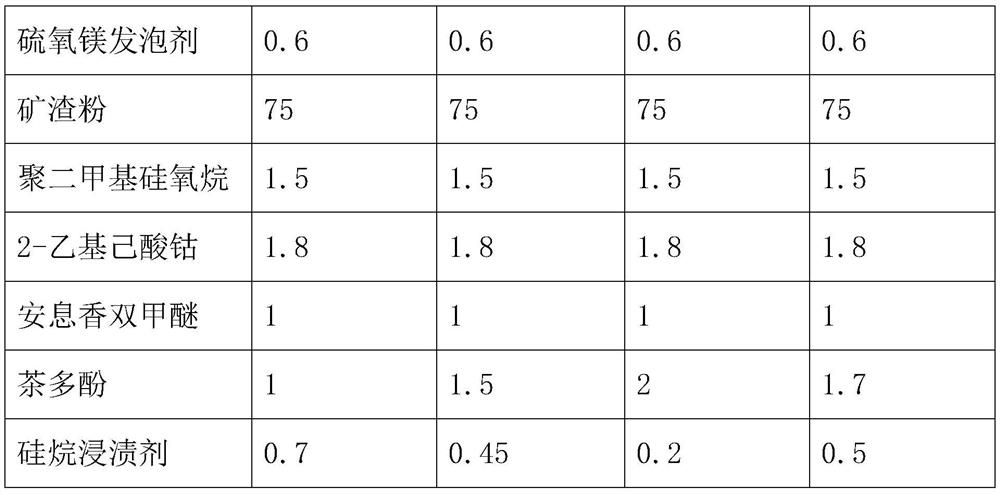

[0082] The raw material components and contents of crack-resistant high-strength aerated blocks are shown in Table 1.

[0083] The time of standing reaction in step (2) is 7.5min;

[0084] In the step (3), the stirring time is controlled to be 5.5 min, and the time for static stopping and curing is controlled to be 9 h.

Embodiment 3

[0086] The difference of embodiment 1 is:

[0087] The raw material components and contents of crack-resistant high-strength aerated blocks are shown in Table 1.

[0088] The time of standing reaction in step (2) is 10min;

[0089] In the step (3), the stirring time is controlled to be 8 min, and the time for static stop and maintenance is controlled to be 10 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com