Hierarchical pore molecular sieve, and preparation method and application thereof

A molecular sieve and multi-stage pore technology, applied in the field of porous materials, can solve the problems of low mass transfer efficiency, single molecular sieve pore structure, and low adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

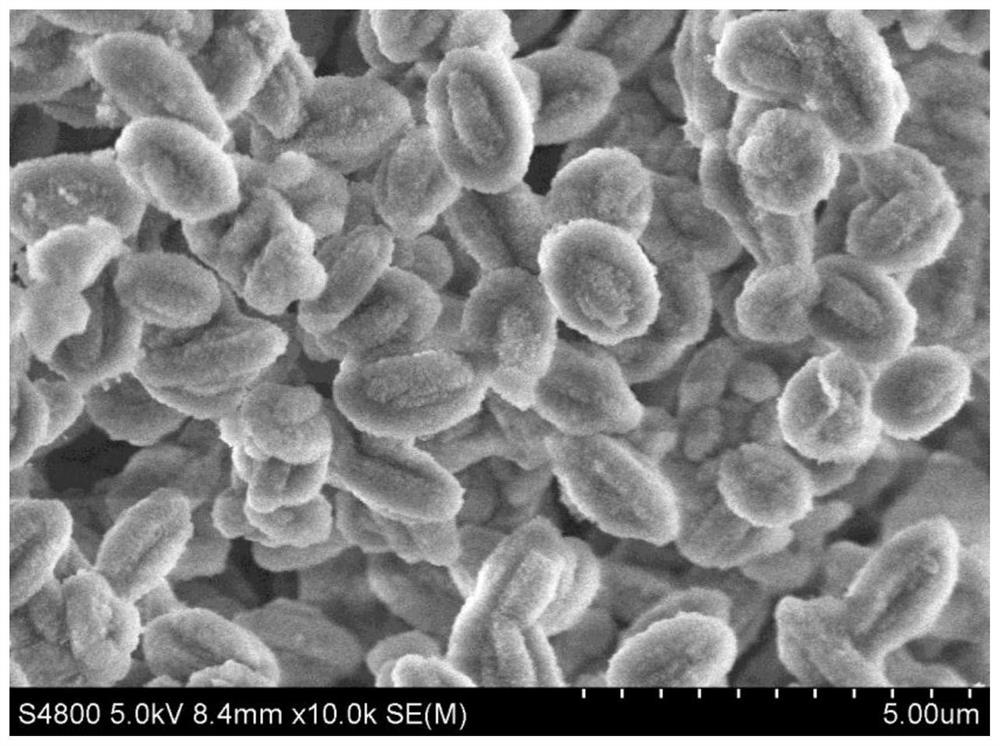

[0064] In another preferred embodiment, the present invention provides a method for synthesizing a hierarchically porous molecular sieve HZSM-5. The HZSM-5 molecular sieve has high adsorption capacity for VOCs components.

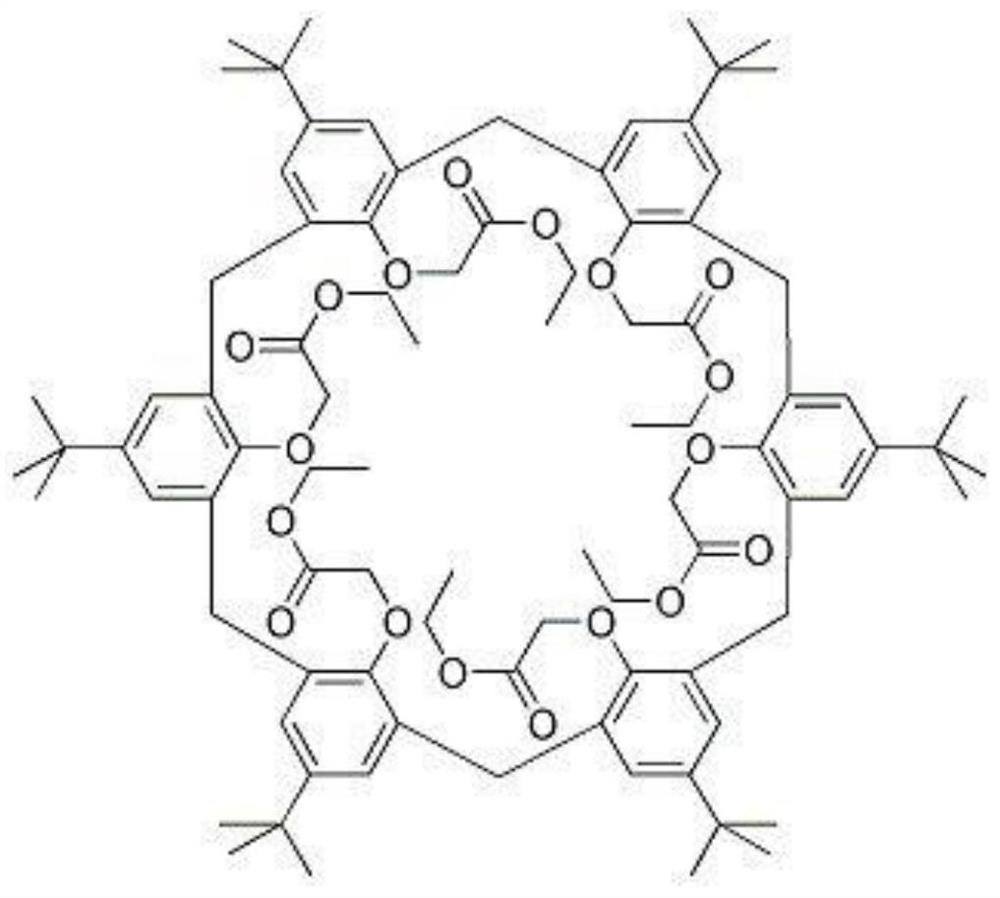

[0065] Preferably, the high adsorption performance HZSM-5 molecular sieve is made of tetraethyl silicate (TEOS), aluminum isopropoxide Al (i-PrO) 3 , tetrapropylammonium hydroxide (TPAOH), cyclic organic compounds, such as β-cyclodextrin (β-CD), polyether F127 or calixarene cyclic organic compounds as raw materials, through steam-assisted synthesis, to obtain High adsorption performance HZSM-5 molecular sieve.

[0066] In another preferred embodiment, the present invention provides a molecular sieve with hierarchical pores, which is characterized by high adsorption capacity HZSM-5 molecular sieve.

[0067] Preferably, in the above-mentioned high adsorption capacity HZSM-5 molecular sieve, the adsorption capacity of the HZSM-5 molecular sieve to VOCs compon...

Embodiment 1

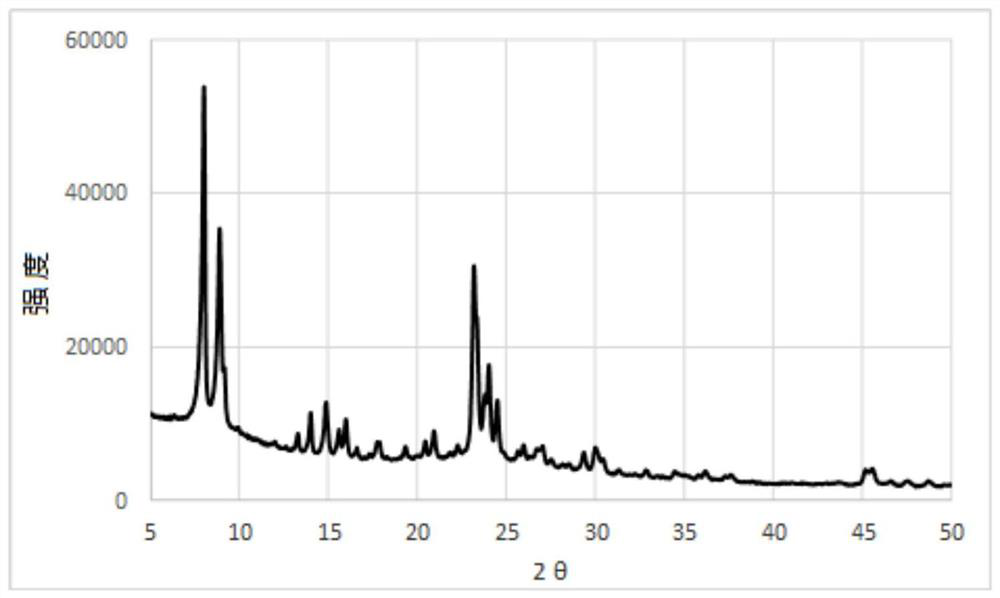

[0075] Embodiment 1: the preparation of HZSM-5 (polyether F127 is hard templating agent) molecular sieve

[0076] (1) Add 2.0g of F127 into 50g of deionized water and stir until completely dissolved.

[0077] (2) After adding 0.50g aluminum isopropoxide (2.48mmol) and 20.8g TEOS (100.0mmol) and stirring vigorously (stirring speed 200r / min) for 4 hours, add 5.1gTPAOH dropwise (20 drops / min), 40°C Continue to stir (stirring speed is 200r / min) to solidify into gel.

[0078] (3) The gel was dried at 60° C. for 8 hours, and then dried at 80° C. for 12 hours until the quality of the gel did not change to obtain a xerogel.

[0079] (4) The xerogel was crystallized at 160° C. for 18 hours by a steam-assisted method, and the product was filtered, washed, and dried at 100° C. overnight.

[0080] Among them, the process of the steam-assisted method is: put the dry gel into the polytetrafluoroethylene liner (volume 120mL) of the autoclave, add 5-15mL water to the 20mL glass sample bottl...

Embodiment 2

[0093]Embodiment 2: Preparation of HZSM-5 (beta-CD is a hard template) molecular sieve

[0094] (1) Add 2.0g of β-CD into 50g of deionized water and stir until completely dissolved.

[0095] (2) After adding 0.25g aluminum isopropoxide (1.24mmol) and 10.4g TEOS (49.92mmol) and stirring vigorously (stirring speed: 200r / min) for 4 hours, add 5.1gTPAOH dropwise (20 drops / min) at 40°C Continue to stir (stirring speed is 200r / min) to solidify into gel.

[0096] (3) The gel was dried at 60° C. for 8 hours, and then dried at 80° C. for 12 hours until the quality of the gel did not change to obtain a xerogel.

[0097] (4) The xerogel was crystallized at 160° C. for 18 hours by a steam-assisted method, and the product was filtered, washed, and dried at 100° C. overnight.

[0098] (5) Calcining at 600°C for 10 hours to remove the organic template, and obtain a multi-order pore molecular sieve HZSM-5.

[0099] The schematic diagram of the molecular structure of β-CD used in this examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com