Automatic metal part welding device

A technology for automatic welding and metal parts, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of welding work influence, small application range, and difficult fixation, etc., and achieve comprehensive welding, enhanced application range, and improved accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

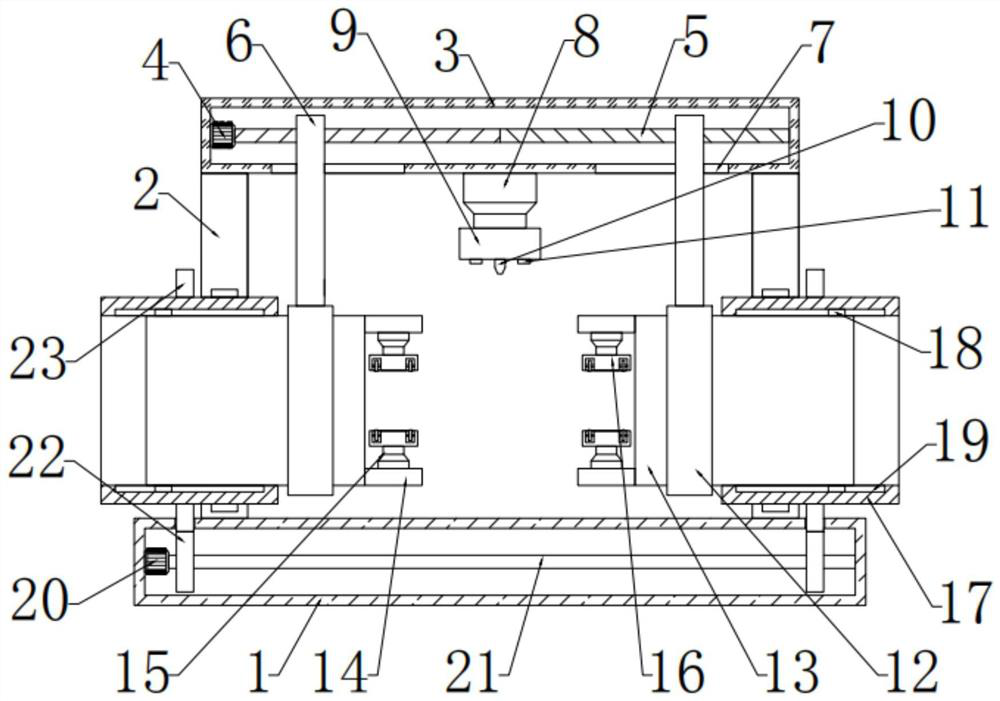

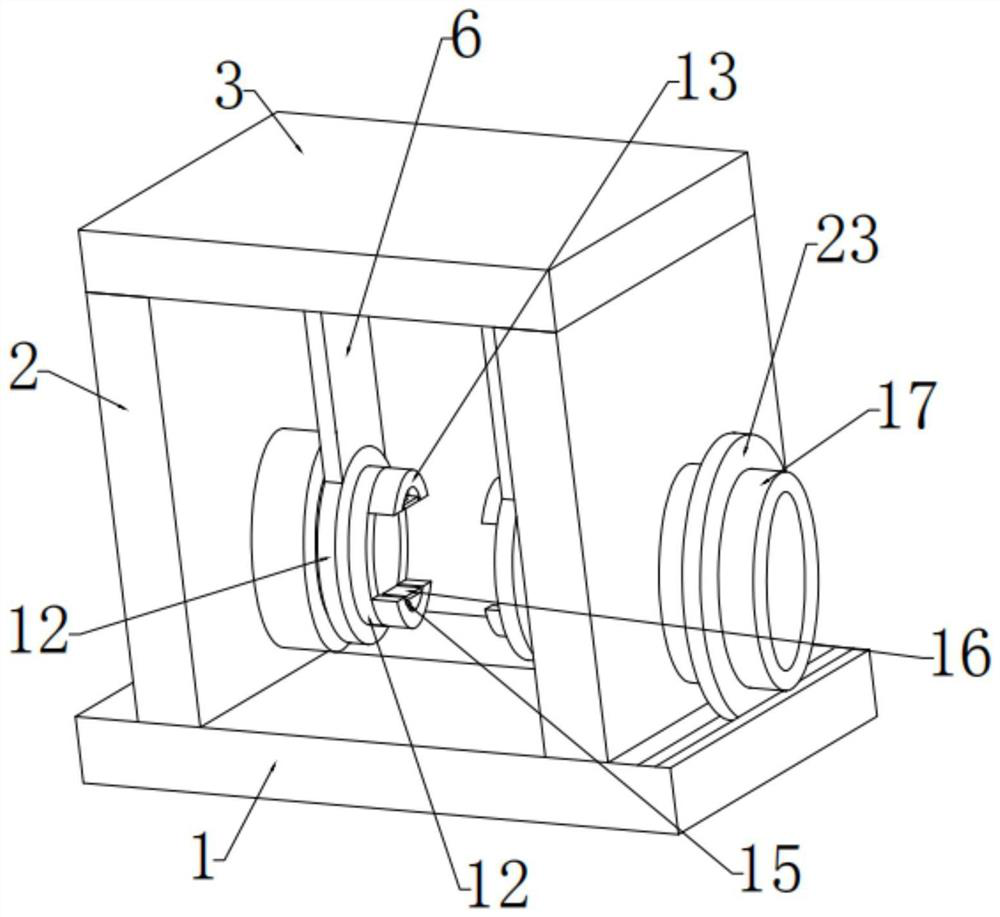

[0024] see Figure 1-3 , in an embodiment of the present invention, an automatic welding device for metal parts, including a base plate 1, the top of the left and right ends of the base plate 1 are fixedly connected with support plates 2, and the support plates 2 on both sides are provided with metal A clamping mechanism for parts, the top of the support plate 2 is fixedly connected with a top plate 3, the bottom of the top plate 3 is provided with a welding mechanism, and the left and right sides of the welding mechanism are provided with adjustment mechanisms connected with the clamping mechanism.

Embodiment 2

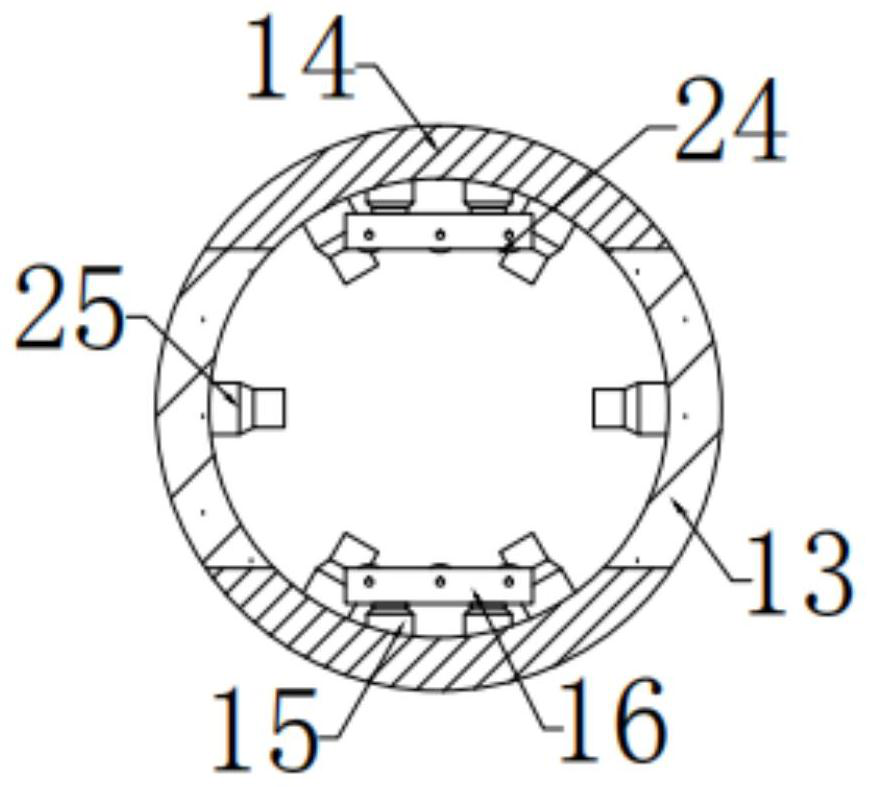

[0026] In this embodiment, the clamping mechanism includes a rotating cylinder 17 arranged on the supporting plate 2 in bearing connection, a fixed tube 13 is arranged inside the rotating cylinder 17, and the upper and lower sides of the fixed tube 13 are fixedly connected and set with limited positions. Block 18, the limit block 18 is slidingly connected with the limit groove 19 arranged on the inner side of the drum 17, and a plurality of third telescopic rods 25 are fixedly connected on the inner side wall of the fixed tube 13, and the fixed tube 13 is close to The upper and lower ends of one side of the welding mechanism are fixedly connected with a baffle plate 14, and the opposite side of the baffle plate 14 on both sides is fixedly connected with a second telescopic rod 15, and the other end of the second telescopic rod 15 is fixedly connected with a Clamping plate 16, by setting clamping mechanism, utilizes clamping plate 16, can provide fixing to plate or irregular met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com