Integrated sink having steam heating module

A heating module and steam technology, applied in the field of kitchen appliances, can solve the problems that do not meet the requirements of consumers' healthy water, affect the steam generation efficiency of the steam oven, and reduce the storage volume of the steam oven, so as to improve the quality of healthy water and increase the steam The effect of generating efficiency and improving the utilization of kitchen space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the electrical connection includes an electrical connection and a communication connection, wherein the communication connection includes a wired communication connection and a wireless communication connection.

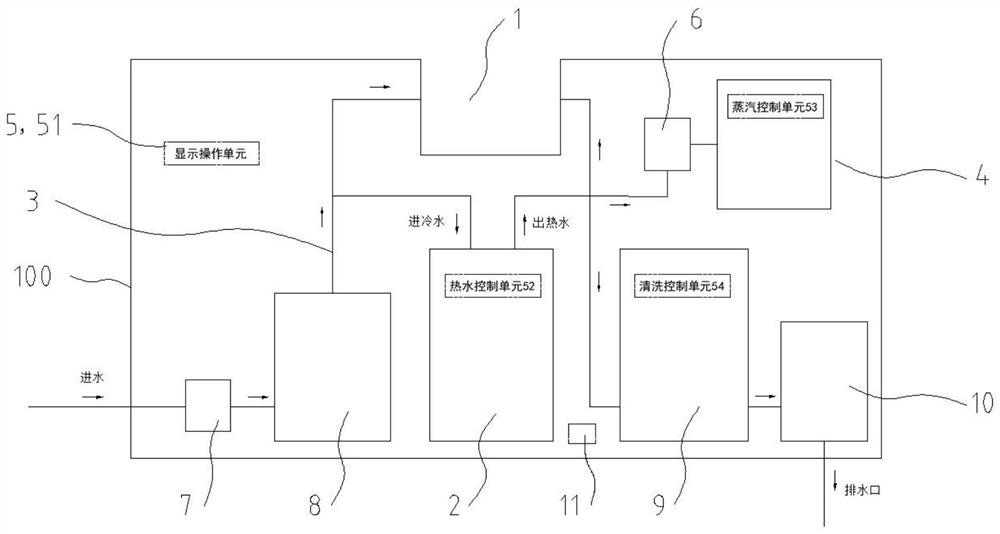

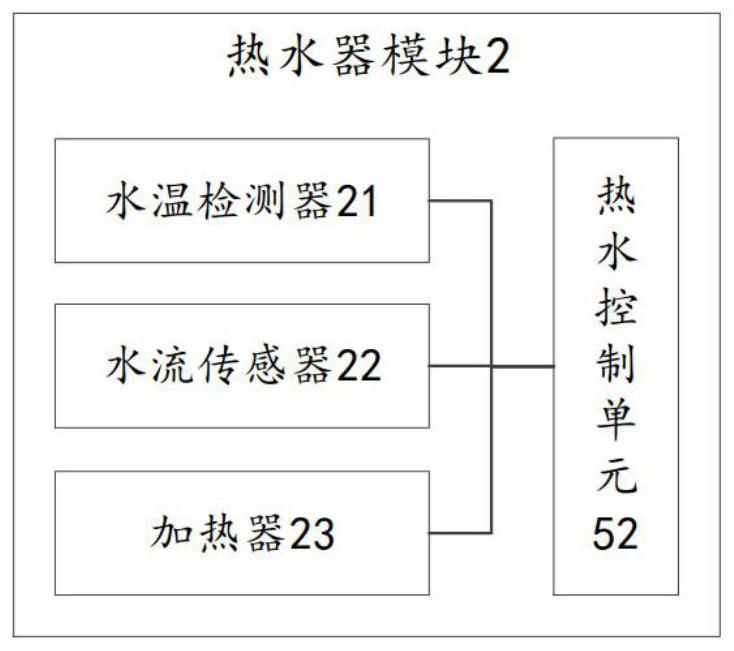

[0029] like figure 1 As shown, an integrated sink with a steam heating module includes a cabinet body 100 , a sink 1 , a water heater module 2 , a main water inlet pipe 3 , a steam heating module 4 for cooking food, a water treatment module 8 and a control module 5 . The cabinet body 100 is provided with a water tank installation hole (not shown in the figure), and the water tank 1 is embedded in the water tank installation hole. Both the water heater module 2 and the steam heating module 4 are arranged in the cabinet body 100 , and the hot water outlet of the water heater module 2 communicates with the hot water inlet of the water tank 1 and the water injection port of the steam heating module 4 respectively. At least part of the main wat...

Embodiment 2

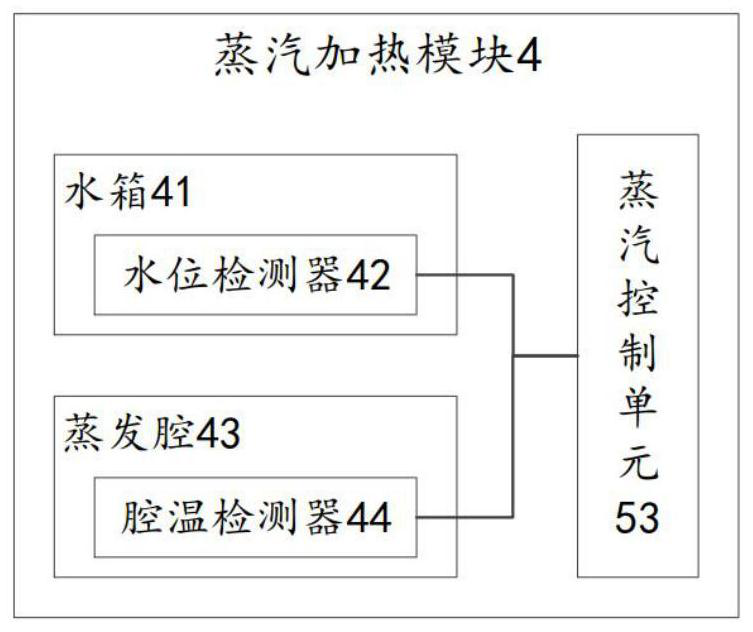

[0069] The difference between this embodiment and Embodiment 1 is that the control logic of the steam heating module 4 is different. Specifically, the control parameters include temperature information, and the control module 5 can control the working state of the water heater module 2 according to the temperature information monitored by the cavity temperature detector 44 .

[0070] More specifically, the temperature information includes a preheating temperature value. When the chamber temperature detector 44 detects that the internal temperature of the evaporation chamber 43 reaches the preheating temperature value, the control module 5 is also used to obtain and judge whether the outlet water temperature of the water heater module 2 reaches the temperature threshold, and control the water heater module 2 according to the judgment result. Whether to heat. Thus, the internal temperature of the evaporation chamber 43 is monitored in real time by the chamber temperature detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com