Device and process for packaging UVC LED chip on wafer

A chip and wafer technology, applied in the field of packaging devices, can solve problems such as damage to wafer circuits, and achieve the effect of facilitating wafer slotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

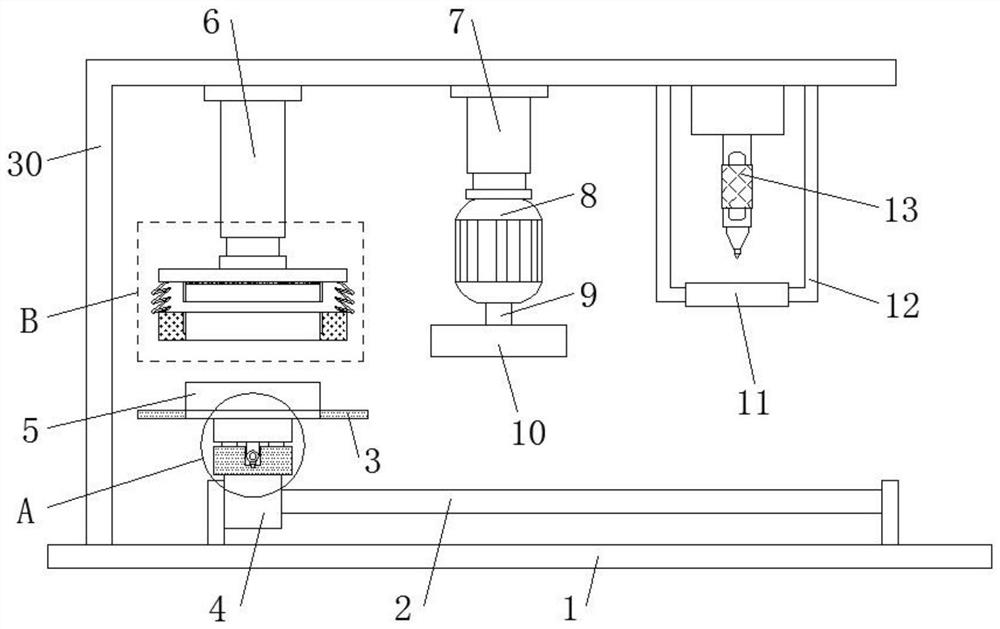

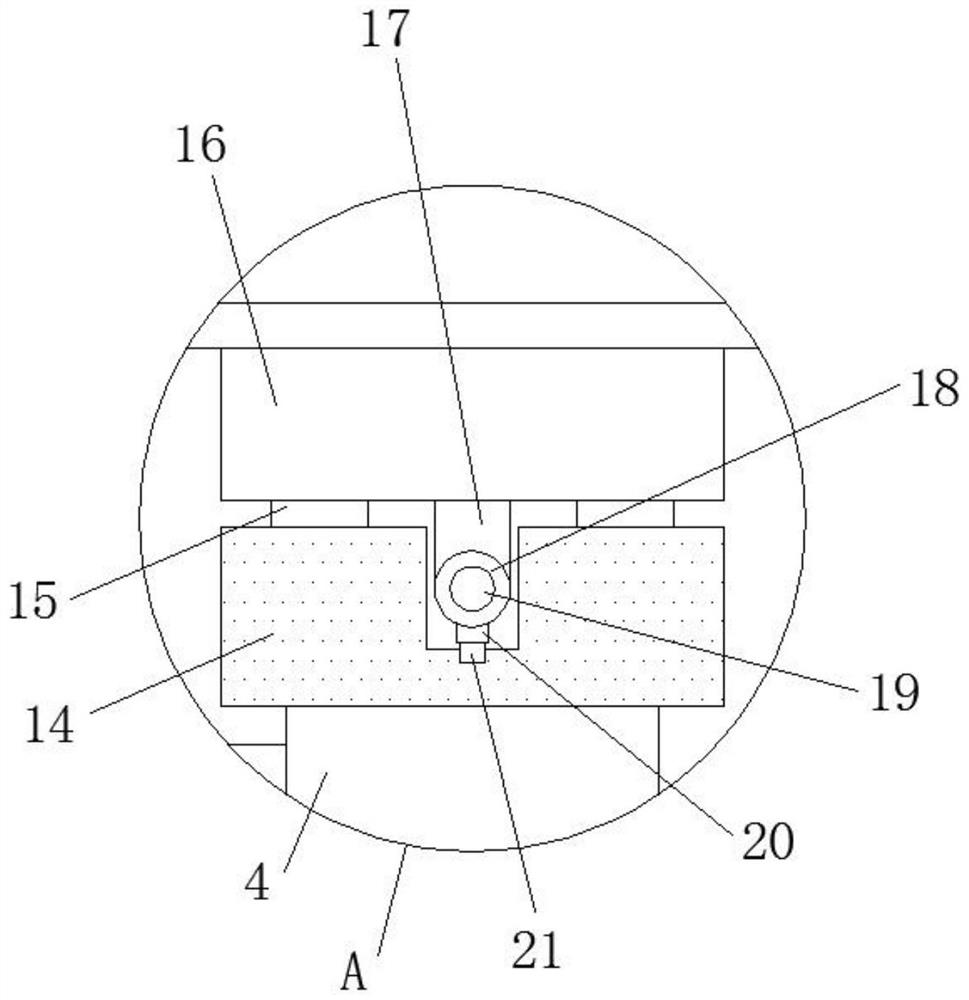

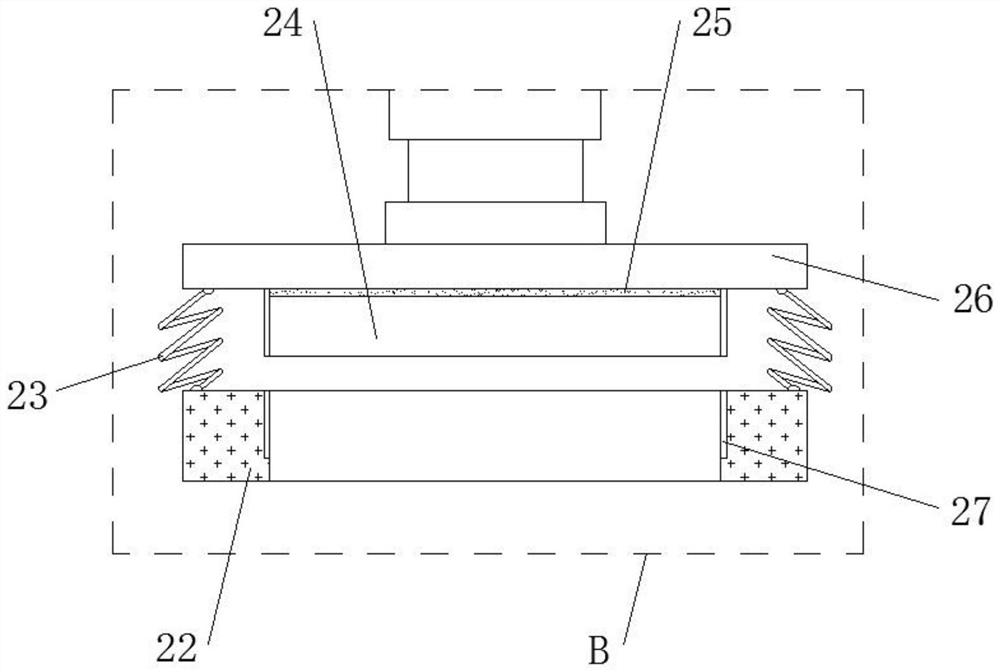

[0026] refer to Figure 1-4 , a device for packaging UVC LED chips on a wafer, including a base plate 1 and an L-shaped frame 30, the L-shaped frame 30 is fixed on the top outer wall of the base plate 1 by bolts, and the L-shaped frame 30 is inverted, and the base plate 1 An electric slide rail 2 is fixed on the outer wall of the top by bolts, and a slider 4 is slidably connected to one side of the outer wall of the electric slide rail 2. The first electric telescopic rod 6 is fixed by bolts, and one end of the extension rod of the first electric telescopic rod 6 is provided with a coating mechanism. Rod 7, one end of the extension rod of the second electric telescopic rod 7 is fixed with a micromotor 8 by a bolt, and one end of the output shaft of the micromotor 8 is keyed to a transmission shaft 9, and a grinding wheel 10, L A slotting mechanism is provided at a position close to the second electric telescopic rod 7 on the top inner wall of the jig 30 .

[0027] In the pre...

Embodiment 2

[0032] refer to Figure 5 , a device for packaging UVC LED chips on a wafer. Compared with Embodiment 1, this embodiment has a riser 28 fixed on the bottom outer wall of the bottom plate 1 close to the electric slide rail 2 through bolts, and the riser 28 is close to the electric slide rail. 2 is fixed with hot blower 29 by bolt on the one side outer wall.

[0033] When in use, after the operation is completed, the hot air blower 29 can be started for slight blowing, and the rising hot air is used to dry the wafer by using the principle of rising hot air, so as to avoid direct drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com