Direct-current support film capacitor resistant to large ripple current

A film capacitor and DC support technology, applied in the direction of film/thick film capacitors, capacitors, laminated capacitors, etc., can solve the problems of insufficient ripple current capability and easy internal heating, etc., to increase ripple current capability and reduce Equivalent series resistance ESR, effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

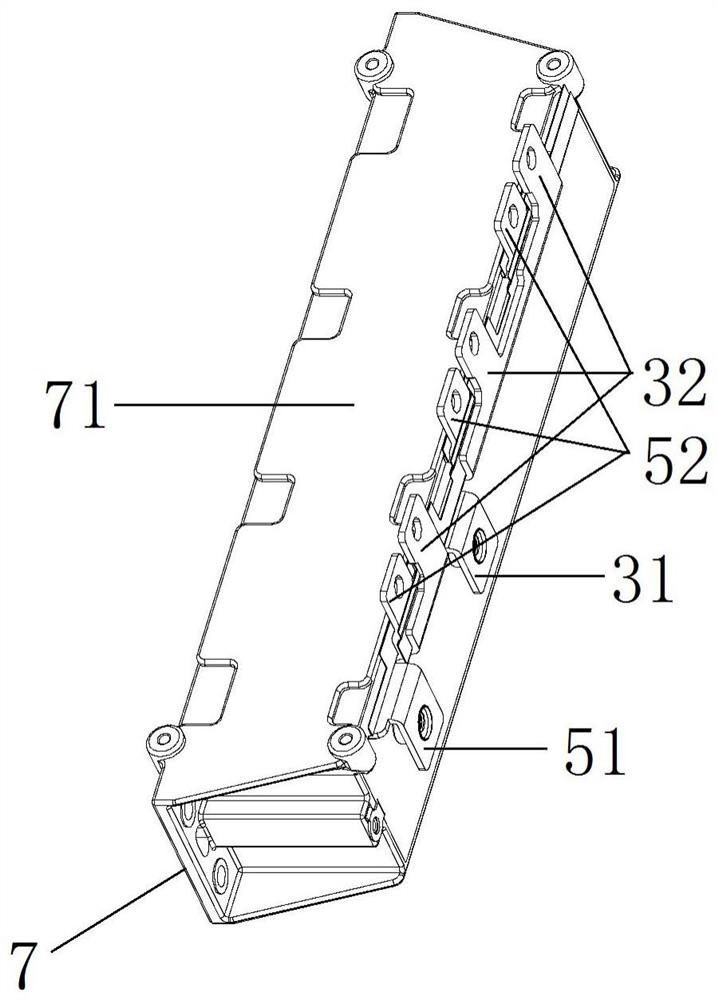

[0030] Shown in conjunction with the accompanying drawings is a specific embodiment of a DC support film capacitor with high ripple current resistance according to the present invention, which mainly includes a capacitor body 1, and the capacitor body 1 includes a core group 2, a lower busbar 3, an insulating layer 4, Upper busbar 5.

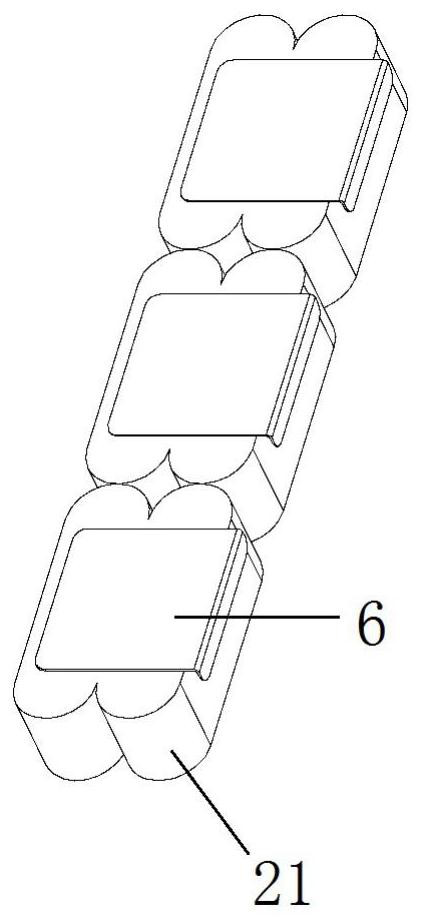

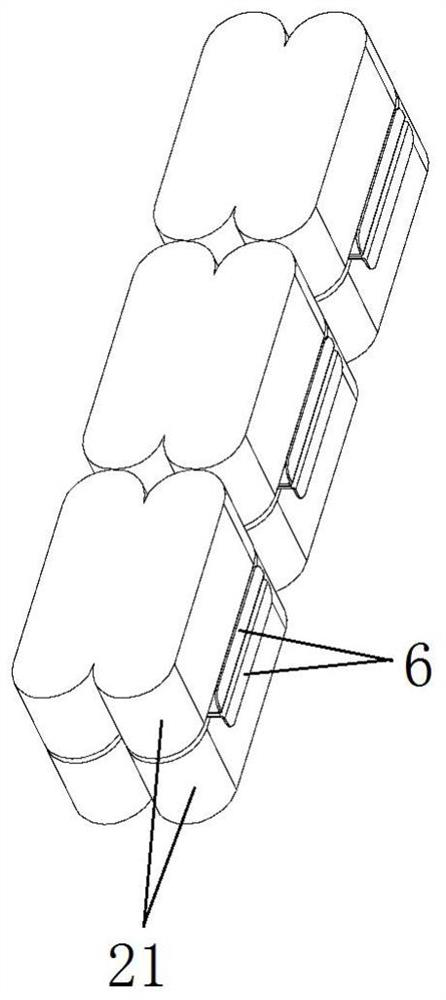

[0031] The core set 2 includes twelve cores 21 , each core 21 is formed by winding a metallized polypropylene film 22 , and the ratio of length to width of the metallized polypropylene film 22 is 3-9:1. The metallized polypropylene film 22 has a metal conductive region 22a, the metal conductive region 22a is provided with a T-type insulating region 22b, and the T-type insulating region 22b has several, distributed along the length direction of the metallized polypropylene film 22 at equal intervals so that The metal conductive region 22a is divided into several regions, and a fuse 22c is provided between two adjacent T-shaped insulating regions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com