In-service hydraulic concrete structure internal loss monitoring and early warning system and method

A hydraulic concrete, monitoring and early warning technology, applied in processing detection response signals, using acoustic wave emission technology for material analysis, instruments, etc., can solve the problem of difficult to achieve accurate positioning of internal damage in large-volume structures, intricate cables, complicated operations, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

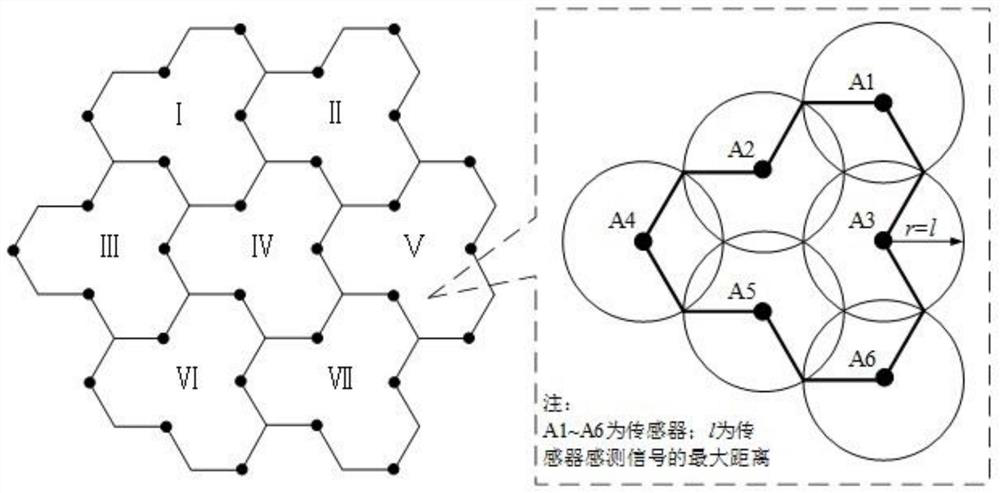

[0208] In order to explain the damage localization method of the present invention more clearly, a specific embodiment is provided here. It should be noted that what is provided here is a simplified two-dimensional acoustic emission source localization test, which is intended to provide a further supplementary description of the damage localization method of the present invention, and should not be construed as a limitation of the present invention.

[0209] The hydraulic concrete mix ratio used in the test of the present invention is the concrete mix ratio recommended by a certain dam, as shown in Table 2.

[0210] Table 2 Hydraulic concrete mix ratio

[0211]

[0212] The cement uses P·C32.5R composite Portland cement, the river sand is medium sand with a fineness modulus F.M=2.81, and the coarse aggregate is continuously graded crushed stone with a particle size of 5-25mm.

[0213] The instrument used is mainly the SAMOSTM acoustic emission acquisition instrument develo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com