Non-coal-pillar longwall mining method based on 120 mode

A mining method and a technology without coal pillars, which can be used in mining equipment, surface mining, mining equipment, etc., can solve problems such as low strength and weak integrity, and achieve the effects of improving efficiency, simple construction, and preventing air leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

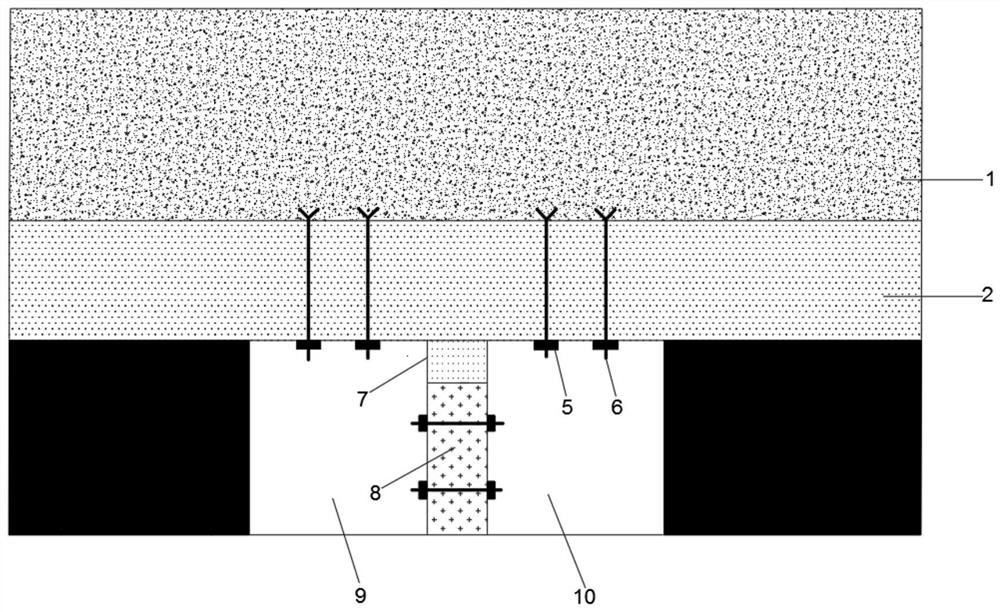

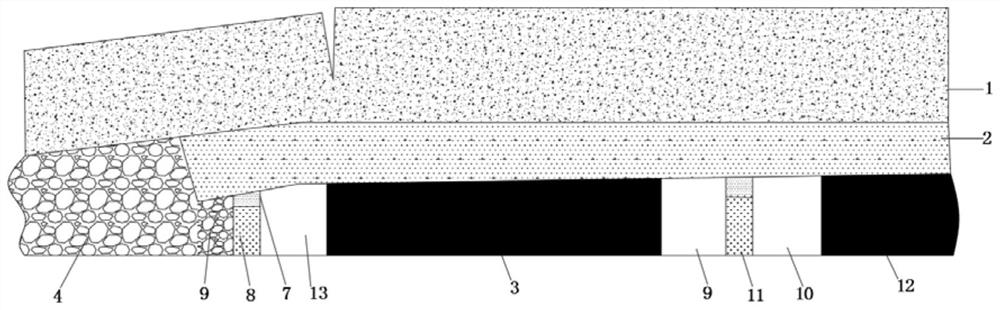

[0027] A longwall mining method without coal pillars based on the 120 model. Specifically, one working face is arranged, a wide roadway is dug and divided into two roadways, and 0 coal pillars are left for mining. Building a supporting wall to isolate the goaf and reserved roadway, so as to ensure the continuity of mining and improve the efficiency of roadway retention and mining, the steps of the method include:

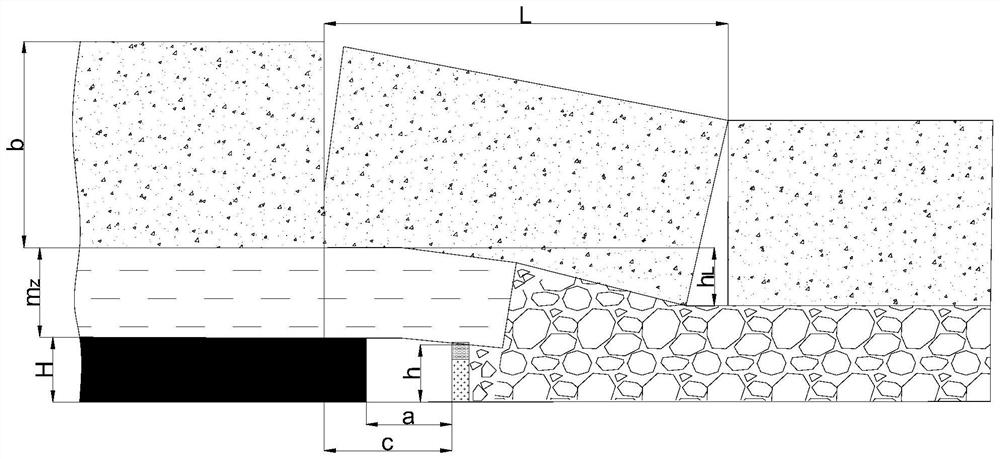

[0028] A. Design the working face within the stope range and divide the mining range. Before mining at the working face, calculate the maximum sinking of the gob-side entry retaining roof according to the known geological conditions and the mechanical structure model of the stope roof subsidence calculation, combined with the mining conditions quantity. Among them, the maximum sinking amount of the roof h L The calculation is specifically:

[0029]

[0030] Among them, C is the distance from the filling body beside the roadway to the fracture line at the end of...

Embodiment 2

[0038] On the basis of Example 1, combined with the mining of the 712 working face of a certain mine, the longwall mining method without coal pillars based on the 120 model will be further explained.

[0039] The 712 working face has a full height at one time mining, the thickness of the coal seam is 4m, and the strike length of the working face is 350m. ). According to the geological conditions, the thickness b of the old roof is determined to be 25.7m, the thickness of the immediate roof is 0.4m, the distance from the roadside filling body to the fracture line at the end of the rock beam on the old roof is 6m, and the span of the rock beam on the old roof is 30m. The crushing expansion coefficient of gangue is taken as 1.3. According to the mining conditions, the design width a of the wide roadway is 8m, and the roadway height h is 3m.

[0040] Calculate the predicted value h of the maximum possible subsidence of the roof of the gob-side entry L :

[0041]

[0042] h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com