Test platform for straddle monorail maintenance equipment

A straddle-type monorail and test platform technology, which is applied in track maintenance, machine/structural component testing, track, etc., can solve problems such as short reserved time, affecting debugging, testing and other research work efficiency, and improve the use of Effects on Stability and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

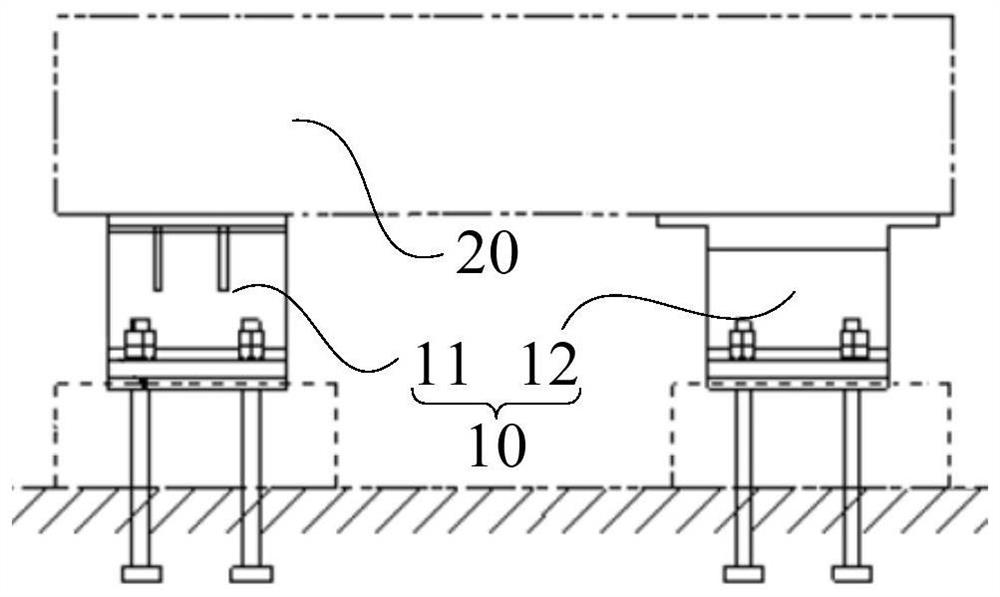

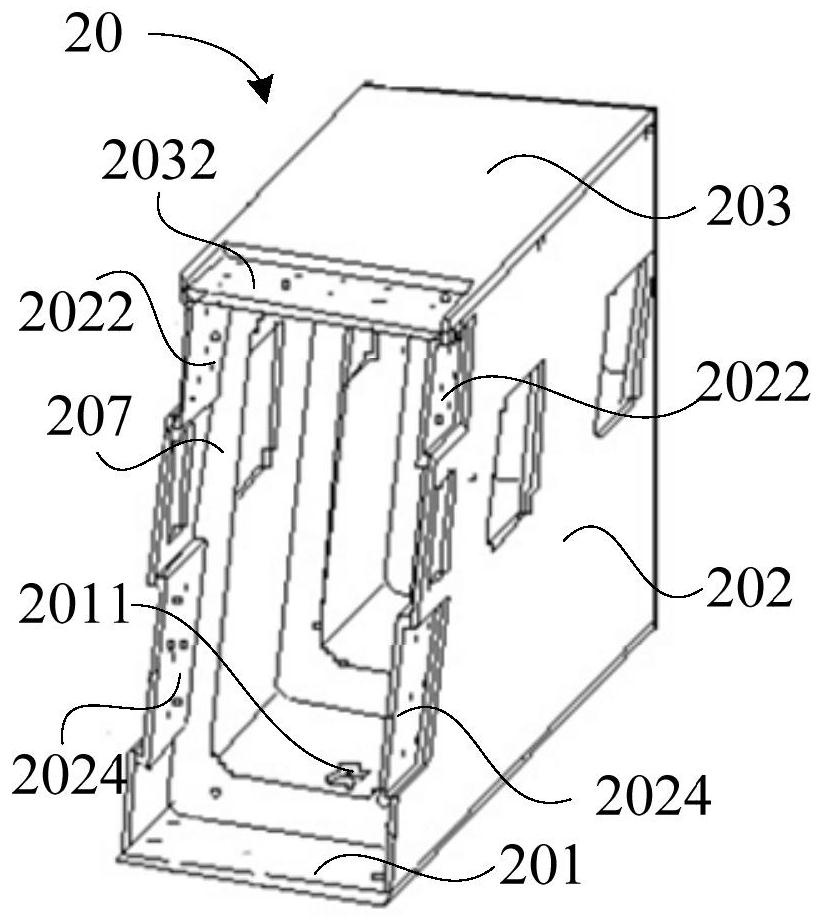

[0078] The total length of the test platform is 115m, including track beam 20 (also called rail beam), fixed support 11, movable support 12, foundation cement abutment (referred to as abutment 13) and stopper 21 (such as a fixed hydraulic buffer stopper) device 21), etc., including straight segment S1 (87.5m), curved segment S2 (15m) and straight segment S3 (12.5m). The number of rail beams is 9, including 8 straight beams, 1 curved beam, and the radius of the curve is 50m. The rail beam type is a steel structure box beam, which adopts a simply supported structure. One end uses a fixed support 11, and the other end uses a movable support. 12. It is connected to the foundation cement abutment by pre-embedded bolts, the fixed end is fully restrained, the movable end is released in the longitudinal direction, the rail beam can move in the longitudinal direction, and each rail beam is connected by finger plates 204. The width of the rail beam running surface can be switched betwee...

specific Embodiment 2

[0084] On the basis of specific embodiment 1, such as Figure 8 As shown, the fixed support 11 adopts a box-type welding structure, which is welded by the top plate A401, the horizontal plate A402, the side plate A403, the bottom plate A404 and the rib plate 405. The thickness of the bottom plate A404 is 30 mm, and the thickness of the rib plate 405 is 15 mm. , the top plate A401, the horizontal plate A402 and the side plate A403 are 20mm thick, and the top plate A401 is connected to the rail beam through 4 bolts. It is understandable that the use of box-type welded structures rather than solid steel beam structures can help reduce costs on the basis of structural strength.

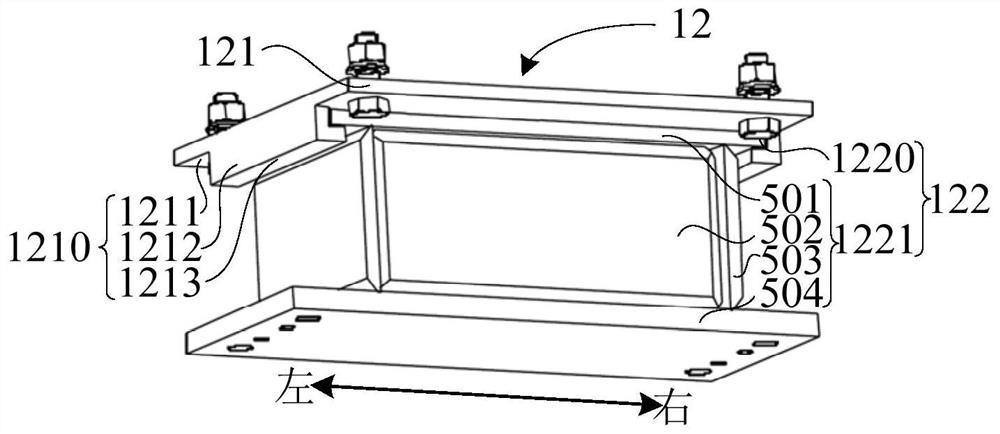

[0085] Such as figure 2 As shown, the movable support 12 is composed of a connecting block (i.e. the sliding part 121) and a welding seat (i.e. the fixing part 122). The connecting block is connected to the rail beam through 4 bolts, and the welding seat also adopts a box-type welding structure. It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com